Discover the Best Deals on Plastic Extruder Machines

By:Admin

One company that has been making waves in the plastic extruder machine market is {}. Their dedication to quality and innovation has set them apart from their competitors, making them a trusted name in the industry. With a focus on customer satisfaction and reliability, they have gained a strong reputation for providing high-quality plastic extruder machines.

The company's dedication to quality is reflected in the pricing of their machines. While their machines may not be the cheapest on the market, they offer a combination of advanced features and reliable performance that make them a worthwhile investment for companies looking to enhance their plastic extrusion processes. The price of their machines is reflective of the high level of engineering and technology that goes into their production, ensuring that customers receive a product that meets their needs and exceeds their expectations.

When considering the price of a plastic extruder machine, it is important to take into account the long-term benefits that come with investing in a quality machine. While it may be tempting to opt for a cheaper option, companies may find that they are sacrificing performance and reliability in the long run. By investing in a high-quality machine, businesses can expect improved efficiency, reduced downtime, and ultimately, a better return on their investment.

The price of a plastic extruder machine from {} reflects the company's commitment to providing the best value for their customers. By offering a range of machines at different price points, they are able to cater to the needs of various businesses, whether big or small. This versatility has made them a popular choice for companies looking to upgrade their plastic extrusion processes.

In addition to the price of their machines, {} also offers excellent customer service and support. With a team of knowledgeable and experienced professionals, they are able to provide assistance and guidance to their customers, helping them to select the right machine for their specific needs. This level of support is invaluable for businesses that are new to plastic extrusion, as it can help them make informed decisions and get the most out of their investment.

As the plastic extruder machine market continues to grow, the pricing of these machines will undoubtedly be a significant consideration for businesses. With the range of options offered by {}, companies can find a machine that fits their budget without compromising on quality. By investing in a plastic extruder machine from {}, businesses can look forward to improved productivity, reduced waste, and ultimately, a stronger competitive edge in their industry.

Company News & Blog

Understanding the Importance of PET Recycling for a Sustainable Future

In a world where sustainability and environmental consciousness have become increasingly important, [Company Name] has taken a significant step towards furthering its commitment to corporate social responsibility through the implementation of a PET recycling program. This initiative aims to reduce the company's carbon footprint and contribute to the global efforts towards a cleaner and greener planet.[Company Name] is a leading global company in the manufacturing and distribution of consumer products, with a strong emphasis on quality, innovation, and ethical business practices. With a diverse range of products that cater to the needs of consumers worldwide, the company has always been at the forefront of industry trends and advancements.Recognizing the growing concern for environmental preservation, [Company Name] has made a conscious effort to incorporate sustainability into its business operations. One of the key measures taken by the company is the implementation of a PET recycling program. PET, or polyethylene terephthalate, is a commonly used plastic material that is widely utilized in the production of bottles, containers, and packaging materials. Unfortunately, PET waste has become a major environmental concern, as it is non-biodegradable and poses a significant threat to the ecosystem.In response to this pressing issue, [Company Name] has initiated a comprehensive PET recycling program that seeks to address the challenges posed by PET waste. The program encompasses the collection, processing, and recycling of PET materials, with the ultimate goal of reducing the environmental impact of the company's products. By implementing a closed-loop system for PET recycling, [Company Name] aims to minimize the use of virgin plastics and promote a circular economy that prioritizes sustainability and resource conservation.As part of the PET recycling program, [Company Name] has established strategic partnerships with recycling facilities and organizations that specialize in the processing of PET materials. These collaborations have enabled the company to streamline its recycling operations and ensure that the collected PET waste is efficiently converted into reusable materials. By leveraging the expertise of its partners, [Company Name] has been able to optimize the recycling process and achieve higher rates of material recovery, thus contributing to the reduction of plastic pollution and the conservation of natural resources.Furthermore, [Company Name] has been actively promoting awareness and education about PET recycling, both internally among its employees and externally to its customers and stakeholders. Through various communication channels and outreach initiatives, the company has been advocating for responsible plastic use and encouraging the adoption of sustainable practices. By fostering a culture of environmental stewardship, [Company Name] is striving to instill a sense of collective responsibility for the planet and inspire positive change within its industry and beyond.The implementation of the PET recycling program underscores [Company Name]'s unwavering commitment to environmental sustainability and corporate citizenship. By taking proactive steps to mitigate the environmental impact of its operations, the company is setting a positive example for its peers and demonstrating its dedication to making a meaningful difference in the fight against plastic pollution. Through the PET recycling initiative, [Company Name] is not only embracing its role as a socially responsible corporate entity but also paving the way for a more sustainable future for generations to come.In conclusion, [Company Name]'s PET recycling program serves as a testament to its progressive approach towards sustainability and environmental stewardship. By embracing the principles of circular economy and resource efficiency, the company is championing a cause that transcends business objectives and resonates with the broader imperative of safeguarding the planet. As [Company Name] continues to expand its PET recycling efforts, it is poised to make a lasting impact on the global environmental landscape while inspiring positive change within the industry and society as a whole.

Efficient Manufacturing Machine for Electrical PVC Pipe Production Unveiled

Title: Revolutionary Electrical PVC Pipe Manufacturing Machine Set to Transform the IndustryIntroduction:In a bid to revolutionize the Electrical PVC Pipe Manufacturing industry, a renowned manufacturing company has developed an innovative machine that promises to streamline the production process while maintaining the highest standards of quality and efficiency. By integrating cutting-edge technology, this groundbreaking device aims to enhance productivity levels, reduce resource consumption, and meet the increasing demands of the market. This article delves into the key features and potential benefits of this game-changing manufacturing machine.Section 1: Background and Industry Overview (150 words)The Electrical PVC Pipe Manufacturing industry has experienced steady growth in recent years due to the increasing demand for electrical infrastructure in both commercial and residential sectors. Traditionally, the manufacturing process involved multiple stages, leading to higher production costs and longer lead times. However, with technological advancements paving the way for innovation, companies are constantly seeking ways to optimize their manufacturing processes.Section 2: Introduction of the Electrical PVC Pipe Manufacturing Machine (150 words)The new Electrical PVC Pipe Manufacturing Machine brings a fresh perspective to the industry by leveraging state-of-the-art technology. This fully automated machine is designed to integrate various production processes, from raw material preparation to final product packaging, into a single streamlined operation. By eliminating the need for manual labor and multiple machines, this device promises to significantly enhance productivity levels, reduce production time, and offer superior quality control.Section 3: Features and Benefits of the Electrical PVC Pipe Manufacturing Machine (250 words)- Advanced Technology: The manufacturing machine utilizes cutting-edge technology, including computer numerical control (CNC) systems, to ensure precise and consistent pipe production. This technology enables measurements and adjustments to be made with unprecedented accuracy, resulting in high-quality end products.- Enhanced Efficiency: Through the integration of various processes into a single operation, the machine maximizes efficiency by minimizing the time required for material handling, equipment setup, and changeovers. This leads to higher production rates, shorter lead times, and reduced manufacturing costs.- Quality Assurance: The machine incorporates automatic quality control mechanisms, which continually monitor and adjust key parameters during the manufacturing process. With this feature, manufacturers can ensure that each PVC pipe produced meets the required specifications, leading to improved customer satisfaction.- Eco-Friendly Operation: The machine is designed with sustainability in mind. Its energy-efficient systems and optimized resource consumption minimize waste, reducing the overall environmental impact of the manufacturing process.- Versatile Production: The machine is adaptable to various pipe sizes and specifications, allowing manufacturers to cater to a wide range of customer requirements. This flexibility ensures a competitive edge in the market, enabling companies to respond quickly to evolving industry demands.Section 4: Conclusion (100 words)The introduction of the Electrical PVC Pipe Manufacturing Machine signifies a milestone in the evolution of the industry. By combining advanced technology, streamlined processes, and environmental sustainability, this game-changing device has the potential to revolutionize the manufacturing landscape. As companies seek ways to increase productivity, reduce costs, and meet customer demands, the utilization of this machine could serve as a catalyst for success in the highly competitive Electrical PVC Pipe Manufacturing industry.

Innovative Plastic Extruder Machine Revolutionizes Manufacturing Processes

**[Extruder Machine Plastic] Revolutionizes Plastic Manufacturing with Cutting-Edge Technology**In a world where plastic products have become an integral part of our daily lives, the demand for efficient and innovative plastic manufacturing solutions has never been higher. That's where [Extruder Machine Plastic] comes in. [Extruder Machine Plastic], a leading manufacturer of plastic extrusion machinery, has been at the forefront of revolutionizing the plastic manufacturing industry with its cutting-edge technology and state-of-the-art equipment. The company has been providing high-quality and reliable extrusion machines to a wide range of industries, including packaging, construction, automotive, and more.Established in [Year], [Extruder Machine Plastic] has quickly earned a reputation for its commitment to innovation, quality, and customer satisfaction. The company's team of experienced engineers and technicians are dedicated to developing advanced extrusion machinery that meets the evolving needs of the industry.One of the key factors that set [Extruder Machine Plastic] apart from its competitors is its relentless focus on research and development. The company continuously invests in exploring new materials, technologies, and manufacturing processes to stay ahead of the curve. This dedication to innovation has allowed [Extruder Machine Plastic] to introduce a range of cutting-edge extrusion machines that are tailored to meet the specific requirements of its clients.One such groundbreaking innovation is the [Extruder Machine Plastic]'s latest extrusion machine, which has been designed to provide unparalleled precision, efficiency, and versatility in plastic manufacturing. This state-of-the-art machine is equipped with advanced features that enable faster production speeds, reduced material wastage, and improved product quality.The [Extruder Machine Plastic] extrusion machine also incorporates smart technology that allows for seamless integration with other manufacturing processes, enhancing overall production efficiency. Additionally, the machine's user-friendly interface and intuitive controls make it easy for operators to monitor and adjust key parameters in real-time, ensuring consistent and reliable production.Furthermore, [Extruder Machine Plastic] places a strong emphasis on sustainability and environmental responsibility. The company's extrusion machines are designed to optimize energy usage and minimize waste, aligning with the growing demand for eco-friendly manufacturing practices.As a testament to its commitment to excellence, [Extruder Machine Plastic] has received numerous accolades and certifications in recognition of its exceptional quality and performance. The company's dedication to continuous improvement and customer satisfaction has cemented its position as a trusted partner for businesses seeking reliable and advanced plastic extrusion solutions.With a global presence and a strong track record of success, [Extruder Machine Plastic] is poised to lead the way in shaping the future of plastic manufacturing. The company's dedication to innovation, quality, and sustainability sets it apart as a pioneer in the industry.As the demand for high-quality plastic products continues to grow, [Extruder Machine Plastic] remains committed to empowering businesses with the tools they need to thrive in today's competitive market. With its cutting-edge technology and unwavering dedication to excellence, [Extruder Machine Plastic] is set to revolutionize the plastic manufacturing industry for years to come.

Discover the Best Deals on Plastic Extruder Machines

The plastic extruder machine market is experiencing a significant development, with the demand for these machines on the rise. As a result of this increasing demand, there has been much interest in the price of these machines. The price of a plastic extruder machine can vary greatly depending on the specifications and features, and it is important for companies to find the right balance between cost and quality.One company that has been making waves in the plastic extruder machine market is {}. Their dedication to quality and innovation has set them apart from their competitors, making them a trusted name in the industry. With a focus on customer satisfaction and reliability, they have gained a strong reputation for providing high-quality plastic extruder machines.The company's dedication to quality is reflected in the pricing of their machines. While their machines may not be the cheapest on the market, they offer a combination of advanced features and reliable performance that make them a worthwhile investment for companies looking to enhance their plastic extrusion processes. The price of their machines is reflective of the high level of engineering and technology that goes into their production, ensuring that customers receive a product that meets their needs and exceeds their expectations.When considering the price of a plastic extruder machine, it is important to take into account the long-term benefits that come with investing in a quality machine. While it may be tempting to opt for a cheaper option, companies may find that they are sacrificing performance and reliability in the long run. By investing in a high-quality machine, businesses can expect improved efficiency, reduced downtime, and ultimately, a better return on their investment.The price of a plastic extruder machine from {} reflects the company's commitment to providing the best value for their customers. By offering a range of machines at different price points, they are able to cater to the needs of various businesses, whether big or small. This versatility has made them a popular choice for companies looking to upgrade their plastic extrusion processes.In addition to the price of their machines, {} also offers excellent customer service and support. With a team of knowledgeable and experienced professionals, they are able to provide assistance and guidance to their customers, helping them to select the right machine for their specific needs. This level of support is invaluable for businesses that are new to plastic extrusion, as it can help them make informed decisions and get the most out of their investment.As the plastic extruder machine market continues to grow, the pricing of these machines will undoubtedly be a significant consideration for businesses. With the range of options offered by {}, companies can find a machine that fits their budget without compromising on quality. By investing in a plastic extruder machine from {}, businesses can look forward to improved productivity, reduced waste, and ultimately, a stronger competitive edge in their industry.

Ultimate Guide to PVC Profile Extrusion: Everything You Need to Know

PVC Profile Extrusion: Revolutionizing the Building IndustryPVC profile extrusion is a process that has been rapidly gaining popularity in the building industry. This innovative technology allows for the creation of high-quality, durable, and cost-effective PVC profiles that are used in a wide range of applications, from windows and doors to electrical conduits and plumbing fixtures.One company that has been leading the way in PVC profile extrusion is {}. With years of experience and expertise in the industry, {} has been at the forefront of developing and implementing advanced extrusion technologies to meet the growing demand for high-performance PVC profiles.The company's state-of-the-art manufacturing facility is equipped with the latest extrusion machinery and tools, allowing them to produce a wide variety of PVC profiles with precision and efficiency. From custom-designed profiles to standard shapes and sizes, {} has the capability to cater to the diverse needs of their clients.One of the key advantages of PVC profile extrusion is the ability to create profiles that offer superior strength, durability, and resistance to harsh environmental conditions. This makes PVC profiles an ideal choice for outdoor applications, where they can withstand exposure to sunlight, moisture, and extreme temperatures without deteriorating.In addition to their durability, PVC profiles are also lightweight, making them easy to handle and install. This, combined with their low maintenance requirements, makes PVC profiles a cost-effective solution for builders and contractors looking to optimize their construction projects.Furthermore, PVC profiles are highly customizable, allowing for the incorporation of various design elements, colors, and finishes. This versatility makes them an attractive choice for architects and designers seeking to achieve a specific aesthetic appeal in their projects.Another significant advantage of PVC profile extrusion is the material's excellent thermal and sound insulation properties. This makes PVC profiles an energy-efficient option for building applications, helping to reduce heating and cooling costs while providing a comfortable indoor environment.Additionally, PVC profiles are inherently resistant to corrosion, rot, and decay, making them a long-lasting solution for both residential and commercial projects. This durability ensures that PVC profiles maintain their structural integrity over time, contributing to the overall longevity of buildings and infrastructure.As environmental sustainability becomes increasingly important in the construction industry, PVC profile extrusion offers a greener alternative to traditional building materials. PVC profiles can be recycled and repurposed, reducing the ecological footprint of construction projects and contributing to a more circular economy.With the versatility, durability, and sustainability of PVC profile extrusion, it is no surprise that this innovative technology has been embraced by manufacturers and builders worldwide. From enhancing the performance of building materials to driving architectural innovation, PVC profiles are revolutionizing the way we build and design the world around us.As {}. continues to evolve and expand their PVC profile extrusion capabilities, they remain committed to delivering the highest quality products and services to their clients. With a focus on innovation, efficiency, and customer satisfaction, {}. is poised to shape the future of the building industry with their cutting-edge PVC profile extrusion technology.

High-Quality PVC Profile Making Machine for Efficient Production

PVC Profile Making Machine Revolutionizing the Plastic IndustryIn recent years, the demand for PVC profiles has been on the rise due to their versatility and durability. With the increasing need for high-quality PVC profiles, the plastic industry has been seeking cutting-edge technologies to meet this demand. One company at the forefront of this technological advancement is {company name}, a leading manufacturer of PVC Profile Making Machines.{company name} has been in the business of manufacturing state-of-the-art PVC Profile Making Machines for over a decade. The company prides itself on its commitment to innovation and excellence, and their machines are known for their high efficiency, reliability, and precision. {company name} has earned a reputation for providing top-notch machinery that meets the evolving needs of the plastic industry.The latest addition to {company name}'s line of PVC Profile Making Machines is set to revolutionize the way PVC profiles are manufactured. This cutting-edge machine incorporates advanced technology and features that improve the speed and accuracy of the production process while ensuring the highest quality output.One of the key features of this new PVC Profile Making Machine is its automated controls, which are designed to streamline the manufacturing process and minimize human error. This not only increases efficiency but also reduces production costs, making it an attractive investment for plastic manufacturers.Additionally, the machine's precise molding capabilities enable the production of complex PVC profiles with intricate designs and tight tolerances. This level of precision is crucial for meeting the stringent quality standards of the industry and satisfying the demands of clients for high-quality PVC profiles.Furthermore, {company name} has integrated sustainability into the design of this new PVC Profile Making Machine. By incorporating energy-efficient components and optimizing the use of raw materials, the machine minimizes its environmental impact while maximizing its output.{company name} is dedicated to providing comprehensive support and training for their customers to ensure the seamless integration of their machines into existing production lines. Their team of technical experts offers professional guidance and assistance to help clients maximize the potential of their PVC Profile Making Machines.The launch of this new PVC Profile Making Machine underscores {company name}'s commitment to driving innovation in the plastic industry. It represents a significant milestone in the company's mission to deliver cutting-edge solutions that address the evolving needs of the market.In response to the unveiling of their latest machine, {company name} CEO stated, "We are proud to introduce this groundbreaking PVC Profile Making Machine, which embodies our dedication to excellence and innovation. Our goal is to empower plastic manufacturers with the tools they need to stay ahead in the industry and meet the growing demand for high-quality PVC profiles."The introduction of this new PVC Profile Making Machine is poised to make a significant impact on the plastic industry. With its advanced technology, precision molding capabilities, and sustainable design, it is set to redefine the standards for PVC profile manufacturing.As the demand for PVC profiles continues to grow, {company name} is poised to play a pivotal role in shaping the future of the plastic industry with its cutting-edge machinery. The company's unwavering commitment to innovation and excellence ensures that it will remain a driving force in the evolution of PVC profile manufacturing.

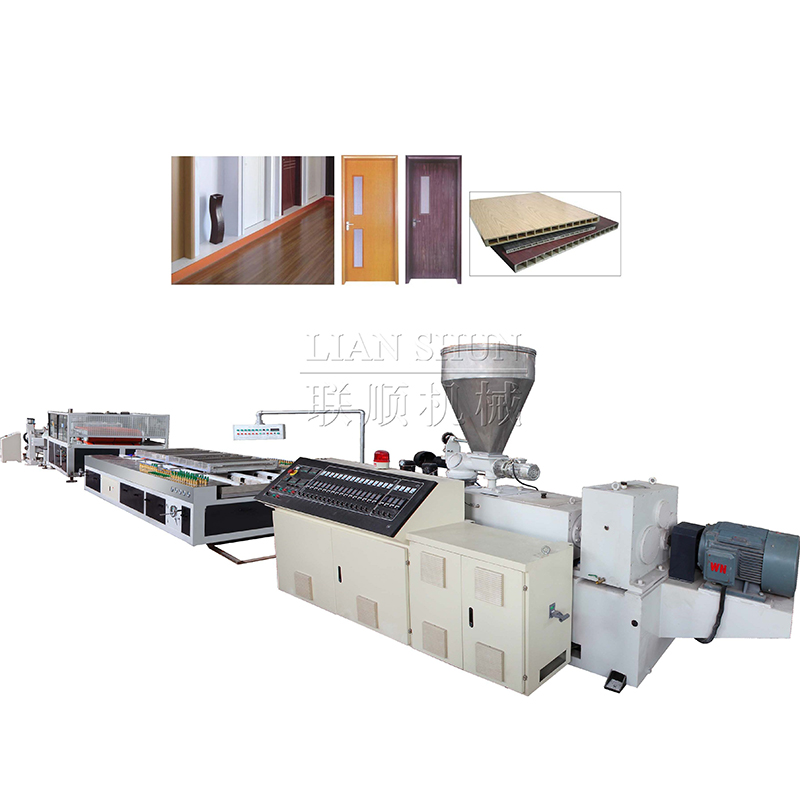

Top Quality WPC Machine for Efficient Wood Plastic Composite Production

The demand for wood-plastic composites (WPC) has been steadily increasing in recent years due to their environmentally friendly nature and their wide range of applications. As a result, the market for WPC machines has been growing as well, with companies constantly seeking innovative and efficient machines to meet the rising demand.One of the top players in the WPC machine industry is {}. The company is renowned for its high-quality machines that offer superior performance and reliability. With years of experience in the industry, {} has established itself as a leading supplier of WPC machines, catering to the needs of a diverse clientele worldwide.The WPC machine offered by {} is a state-of-the-art piece of equipment that is designed to meet the rigorous demands of the industry. It is capable of producing high-quality wood-plastic composites with precision and efficiency. The machine is equipped with advanced technology and features that enable it to process a variety of materials, resulting in WPC products that are both durable and environmentally sustainable.One of the key advantages of the {} WPC machine is its versatility. It is capable of producing a wide range of WPC products, including decking, fencing, and furniture components, among others. This flexibility makes it an ideal choice for companies looking to diversify their product offerings and cater to different market segments.In addition to its exceptional performance, the {} WPC machine is also known for its user-friendly design. It is equipped with an intuitive control system that makes operation easy and efficient. Furthermore, the machine is built to withstand the rigors of continuous operation, ensuring minimal downtime and maximum productivity for its users.It is worth noting that {} is not only a supplier of WPC machines, but also a partner to its clients. The company offers comprehensive support and technical assistance to its customers, ensuring that they are able to maximize the potential of the machine and achieve the best results. This commitment to customer satisfaction has earned {} a solid reputation in the industry.As the demand for WPC products continues to grow, the market for WPC machines is expected to expand as well. With its proven track record and commitment to innovation, {} is well-positioned to capitalize on this trend and remain a top choice for companies seeking reliable and efficient WPC machines.In conclusion, the {} WPC machine is a testament to the company's dedication to providing cutting-edge solutions for the production of wood-plastic composites. With its superior performance, versatility, and customer support, the machine has solidified {}'s position as a leading player in the WPC machine industry. As the market for WPC products continues to thrive, companies can count on {} to meet their production needs and drive their success in this burgeoning sector.

Cutting-Edge Film Recycling Machine Revolutionizes Waste Management

Title: Revolutionary Film Recycling Machine Revolutionizes Waste ManagementIntroduction:In a groundbreaking move towards sustainable waste management, a leading company {} has introduced an innovative Waste Film Recycling Machine. By efficiently recycling plastic film waste, this state-of-the-art machine aims to tackle the global environmental challenge of plastic pollution. Operating on cutting-edge technology, this recycling machine has the potential to revolutionize the way we handle plastic waste.Body:1. The Plastic Pollution Crisis:Plastic pollution has become a pressing global issue, as millions of tons of plastic waste enter our oceans and natural surroundings every year, causing irreversible harm to marine life and ecosystems. Single-use plastic films, such as shopping bags, food packaging, and agricultural films, contribute significantly to this crisis. Recognizing the urgency to address this problem, {} has developed an innovative solution that enables the efficient recycling of plastic films.2. Introducing the Waste Film Recycling Machine:The Waste Film Recycling Machine {} has developed is a cutting-edge piece of technology that can process and recycle plastic films efficiently. This machine employs a multi-step process that includes sorting, shredding, washing, and pelletizing, ensuring a thorough and complete recycling of plastic waste. Its advanced features make it possible to handle a wide range of plastic films, thereby ensuring maximum utilization of resources.3. Sorting and Shredding:The first step of the recycling process involves sorting the plastic films based on their composition and type. The Waste Film Recycling Machine uses advanced sensors and artificial intelligence algorithms to identify and separate different types of plastic films automatically. Then, the machine shreds the films into small pieces, making them easier to handle in subsequent steps.4. Washing and Cleaning:After shredding, the machine initiates a thorough washing and cleaning process to remove any impurities from the plastic film shreds. Through a combination of mechanical agitation, chemical treatment, and water filtration, this process effectively removes dirt, residue, and other contaminants, ensuring the production of high-quality recycled plastic materials.5. Pelletizing:Following the cleaning process, the machine transforms the cleaned plastic film shreds into plastic pellets. These pellets can serve as the raw materials for a plethora of industries, including packaging, textiles, and construction. By replacing virgin plastic materials with recycled plastic pellets, the Waste Film Recycling Machine assists in reducing the demand for fossil fuels and curbing greenhouse gas emissions.6. Environmental and Economic Benefits:The introduction of the Waste Film Recycling Machine brings forth numerous environmental and economic advantages. Firstly, it helps in reducing the strain on landfills and incinerators, as the plastic film waste is diverted from such disposal methods. Additionally, the machine promotes resource conservation by providing a viable way to reuse plastic films effectively. The recycled plastic pellets generated by the machine serve as a sustainable alternative to virgin plastic, contributing to a circular economy.Conclusion:The Waste Film Recycling Machine by {} presents an innovative solution to the growing problem of plastic pollution. By employing cutting-edge technology to recycle plastic films, this machine offers an efficient and sustainable way to manage plastic waste. With the potential to revolutionize waste management practices, this invention brings hope to a greener and cleaner future. By adopting such advancements, we can collectively address the plastic pollution crisis and work towards a more sustainable planet.

Pp Extruder Machine: An Overview of the Latest Equipment in Plastic Extrusion

Pp Extruder Machine has been making waves in the manufacturing industry with its cutting-edge technology and state-of-the-art equipment. The company has been leading the way in providing high-quality extrusion machines that can meet the demands of various industries. With a strong focus on innovation and customer satisfaction, Pp Extruder Machine has established itself as a reliable and trusted partner for businesses in need of efficient and reliable extrusion solutions.The company's success can be attributed to its commitment to delivering top-notch products and services. Pp Extruder Machine takes pride in its team of highly skilled and experienced professionals who work tirelessly to develop and manufacture extrusion machines that are second to none. The company also invests heavily in research and development to stay ahead of the curve and continuously improve its products and processes.Pp Extruder Machine offers a wide range of extrusion machines to cater to the diverse needs of its clients. Whether it's for the production of plastic pipes, profiles, sheets, or other plastic products, the company has the right equipment to get the job done efficiently and effectively. Its extruders are designed to deliver high productivity, energy efficiency, and consistent quality, helping businesses streamline their production processes and achieve better results.One of the key factors that sets Pp Extruder Machine apart from its competitors is its dedication to customer satisfaction. The company works closely with its clients to understand their specific requirements and provide customized solutions that best suit their needs. Pp Extruder Machine doesn't just sell machines – it offers comprehensive support and after-sales services to ensure that its clients get the most out of their investment and achieve their production goals.In addition to its commitment to quality and customer satisfaction, Pp Extruder Machine also places great emphasis on environmental sustainability. The company understands the importance of responsible manufacturing and has implemented eco-friendly practices in its operations. Its extrusion machines are designed to minimize waste and energy consumption, helping businesses reduce their environmental footprint while maximizing their productivity.Furthermore, Pp Extruder Machine is dedicated to staying abreast of the latest industry trends and technological advancements. The company continually upgrades its equipment and processes to incorporate the latest innovations, ensuring that its clients have access to the most advanced extrusion solutions available. By staying at the forefront of technology, Pp Extruder Machine enables businesses to stay competitive and meet the evolving demands of the market.Looking ahead, Pp Extruder Machine is poised to further expand its presence in the global market. The company is committed to forging partnerships with businesses worldwide and providing them with top-of-the-line extrusion machines that deliver exceptional performance and value. With its solid track record, dedication to excellence, and forward-looking approach, Pp Extruder Machine is well-positioned to maintain its leadership in the industry and continue driving innovation and progress.In conclusion, Pp Extruder Machine has established itself as a leading provider of high-quality extrusion solutions. With its focus on innovation, customer satisfaction, environmental sustainability, and technological advancement, the company has set the bar high for manufacturing excellence. Businesses in search of reliable and efficient extrusion machines need look no further than Pp Extruder Machine for all their needs.

PVC Pipe Manufacturing Unit Experiences Growth in Production

PVC Pipe Manufacturing Unit to Enhance Production CapacityWith the ever-growing demand for high-quality PVC pipes in the construction and infrastructure sectors, {Company Name} is proud to announce the expansion of its PVC pipe manufacturing unit. The company has been a leading player in the industry for over two decades, known for its commitment to innovation, quality, and customer satisfaction.The expansion of the PVC pipe manufacturing unit comes as a response to the increasing demand for PVC pipes in various applications such as water supply, drainage, irrigation, and sewerage. With the new and improved production capacity, {Company Name} aims to meet the growing needs of its customers while maintaining its uncompromising standards of product quality.The upgraded manufacturing unit is equipped with state-of-the-art machinery and technology, designed to enhance the efficiency and precision of the production process. This includes advanced extrusion lines, automated cutting and packaging systems, and quality control measures at every stage of production. These advancements will not only increase the overall output of PVC pipes but also ensure that each product meets the company's stringent quality standards.In addition to increasing production capacity, the expansion of the PVC pipe manufacturing unit will also create new employment opportunities, contributing to the local economy and furthering the company's commitment to social responsibility. {Company Name} has always placed importance on fostering a positive impact on the communities in which it operates, and the expansion of the manufacturing unit is a testament to this commitment.Furthermore, the company has also invested in research and development to innovate and introduce new product lines that cater to the evolving needs of its customers. This includes the development of specialized PVC pipes that offer enhanced durability, corrosion resistance, and environmental sustainability. With a focus on sustainability and environmental responsibility, {Company Name} is dedicated to providing products that not only meet industry standards but also contribute to a greener and more efficient infrastructure.The expansion of the PVC pipe manufacturing unit is a significant milestone for {Company Name} and underscores its position as a leader in the PVC pipe industry. The company's dedication to quality, innovation, and customer satisfaction has set it apart in a competitive market, and the expansion of its manufacturing capabilities reaffirms its commitment to meeting the growing demands of its customers.As {Company Name} continues to grow and evolve, it remains dedicated to upholding its core values of excellence, integrity, and sustainability. The expansion of the PVC pipe manufacturing unit is a reflection of these values and will enable the company to better serve its customers and contribute to the development of crucial infrastructure projects.In conclusion, the expansion of the PVC pipe manufacturing unit at {Company Name} represents a significant step forward for the company and the industry as a whole. With increased production capacity, advanced technology, and a focus on innovation, {Company Name} is well-positioned to meet the growing demand for high-quality PVC pipes and further solidify its reputation as a leader in the market. As the company continues to invest in its manufacturing capabilities, it remains committed to delivering exceptional products and driving positive change in the infrastructure and construction sectors.