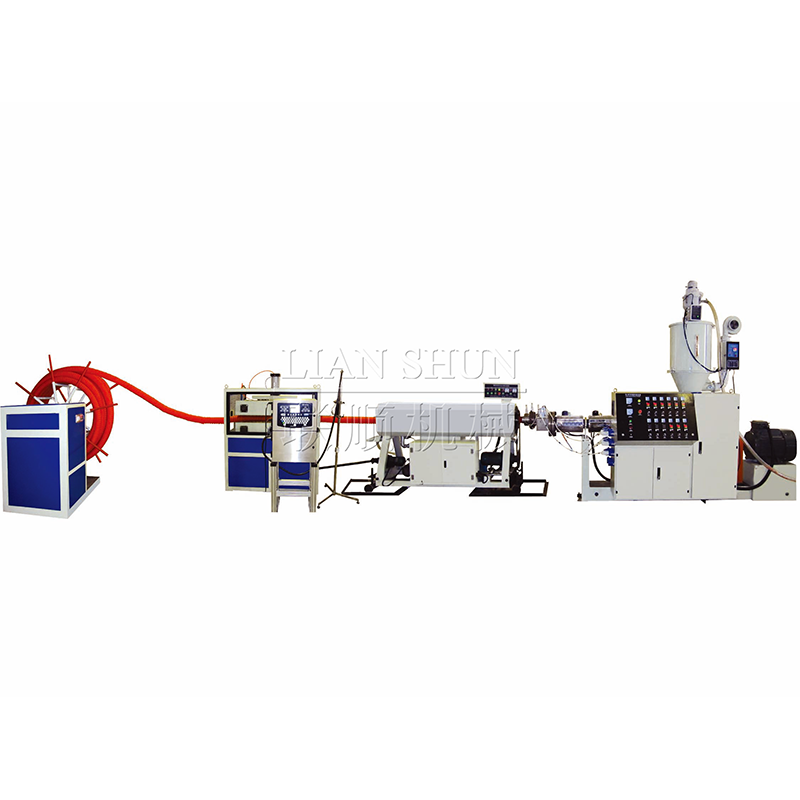

High-Quality PPR Pipe Extruding Machine for Efficient Production

By:Admin

{Company Name} is proud to announce the launch of its latest innovation, the Ppr Pipe Extruding Machine. This state-of-the-art machine is designed to revolutionize the production of Ppr pipes, offering a range of advanced features and capabilities that set it apart from traditional manufacturing methods.

The Ppr Pipe Extruding Machine is equipped with cutting-edge technology, including high-precision extrusion systems and automatic control functions, to ensure the highest quality and efficiency in pipe production. This machine is designed to meet the growing demand for Ppr pipes in various industries, such as plumbing, construction, and agricultural irrigation.

One of the key features of the Ppr Pipe Extruding Machine is its ability to produce pipes with superior strength, durability, and resistance to corrosion. This is achieved through the use of high-quality materials and advanced manufacturing processes, which result in pipes that can withstand high pressure and temperature, making them ideal for a wide range of applications.

In addition to its exceptional quality, the Ppr Pipe Extruding Machine is also highly efficient, with a high-speed production capacity that allows for the rapid manufacturing of pipes in large quantities. This makes it an ideal solution for companies looking to increase their production output and meet the growing demand for Ppr pipes in the market.

Furthermore, the Ppr Pipe Extruding Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive control panel and automated functions enable operators to oversee the production process with ease, while its durable construction and low maintenance requirements ensure long-term reliability and cost-effectiveness.

The launch of the Ppr Pipe Extruding Machine represents a significant milestone for {Company Name}, as it further solidifies our position as a leading provider of innovative solutions for the manufacturing industry. We are committed to pushing the boundaries of what is possible in pipe production, and the introduction of this machine is a testament to our dedication to delivering excellence and value to our customers.

We believe that the Ppr Pipe Extruding Machine has the potential to transform the way Ppr pipes are produced, offering a more efficient, cost-effective, and sustainable solution that meets the evolving needs of the market. As such, we are excited to bring this cutting-edge technology to our customers and partners, to help them stay ahead of the competition and drive growth in their respective industries.

With the launch of the Ppr Pipe Extruding Machine, {Company Name} is poised to set new standards in pipe production, offering unmatched quality, efficiency, and reliability that will benefit our customers and contribute to the advancement of the manufacturing industry as a whole. We are confident that this machine will be a game-changer for companies looking to enhance their production capabilities and achieve new levels of success in the market.

In conclusion, the Ppr Pipe Extruding Machine from {Company Name} is a game-changing innovation that is set to redefine the production of Ppr pipes, offering superior quality, efficiency, and reliability that will benefit companies across various industries. With its advanced features and user-friendly design, this machine represents a significant leap forward in the manufacturing industry, and we are excited to bring its potential to our customers and partners around the world.

Company News & Blog

Efficient and Eco-Friendly Pet Flakes Washing Machine for Recycling Industry

Pet Flakes Washing Machine, an innovative solution to plastic waste management, is a revolutionary step towards a sustainable future. This advanced machine is designed to effectively clean and recycle PET (Polyethylene Terephthalate) flakes, thereby contributing to the reduction of plastic pollution. The company, a leading manufacturer of industrial machinery, is dedicated to providing cutting-edge technology for environmental conservation and sustainable development.With the increasing global concern over plastic waste, the demand for efficient recycling solutions has never been greater. The Pet Flakes Washing Machine addresses this pressing issue by offering an efficient and cost-effective method for cleaning and processing PET flakes. This not only helps in reducing the environmental impact of plastic waste but also contributes to the circular economy by promoting the reuse of materials.The machine is equipped with advanced washing and drying equipment, which ensures that the PET flakes are thoroughly cleaned and prepared for further processing. Its efficient filtration and separation system effectively removes contaminants and impurities, resulting in high-quality recycled PET flakes. The entire process is automated, ensuring consistency and reliability in the output.In addition to its technological prowess, the company behind the Pet Flakes Washing Machine is committed to sustainability and environmental responsibility. Their dedication to research and development has led to the creation of a machine that not only meets industry standards but also prioritizes energy efficiency and resource conservation. By utilizing this machine, businesses can not only contribute to the reduction of plastic waste but also improve their overall environmental footprint.The company's approach to sustainability extends beyond just the design of the machine. They also offer comprehensive support and training for their clients, empowering them to effectively operate and maintain the equipment. This commitment to customer satisfaction ensures that businesses can seamlessly integrate the Pet Flakes Washing Machine into their operations, further promoting sustainable practices within the industry.Furthermore, the company's focus on innovation and continuous improvement sets them apart in the market. They constantly strive to enhance their products and services, staying at the forefront of technological advancements in the field of plastic recycling. This dedication to excellence positions them as a reliable and forward-thinking partner for businesses seeking to invest in sustainable solutions.The Pet Flakes Washing Machine is not just a piece of equipment; it represents a significant step towards a cleaner and greener future. By offering a viable and efficient solution for PET flake recycling, the company is contributing to the global efforts to mitigate the environmental impact of plastic waste. With their commitment to sustainability, innovation, and customer satisfaction, they are poised to make a lasting impact on the industry and the planet.As the world continues to grapple with the challenges posed by plastic waste, the introduction of the Pet Flakes Washing Machine brings a ray of hope. It showcases the potential for technology to drive positive change and offers a tangible solution for businesses looking to embrace sustainability. With the support and expertise of the company behind this groundbreaking innovation, the adoption of this technology is set to make a meaningful difference in the fight against plastic pollution.

Pp Extruder Machine: An Overview of the Latest Equipment in Plastic Extrusion

Pp Extruder Machine has been making waves in the manufacturing industry with its cutting-edge technology and state-of-the-art equipment. The company has been leading the way in providing high-quality extrusion machines that can meet the demands of various industries. With a strong focus on innovation and customer satisfaction, Pp Extruder Machine has established itself as a reliable and trusted partner for businesses in need of efficient and reliable extrusion solutions.The company's success can be attributed to its commitment to delivering top-notch products and services. Pp Extruder Machine takes pride in its team of highly skilled and experienced professionals who work tirelessly to develop and manufacture extrusion machines that are second to none. The company also invests heavily in research and development to stay ahead of the curve and continuously improve its products and processes.Pp Extruder Machine offers a wide range of extrusion machines to cater to the diverse needs of its clients. Whether it's for the production of plastic pipes, profiles, sheets, or other plastic products, the company has the right equipment to get the job done efficiently and effectively. Its extruders are designed to deliver high productivity, energy efficiency, and consistent quality, helping businesses streamline their production processes and achieve better results.One of the key factors that sets Pp Extruder Machine apart from its competitors is its dedication to customer satisfaction. The company works closely with its clients to understand their specific requirements and provide customized solutions that best suit their needs. Pp Extruder Machine doesn't just sell machines – it offers comprehensive support and after-sales services to ensure that its clients get the most out of their investment and achieve their production goals.In addition to its commitment to quality and customer satisfaction, Pp Extruder Machine also places great emphasis on environmental sustainability. The company understands the importance of responsible manufacturing and has implemented eco-friendly practices in its operations. Its extrusion machines are designed to minimize waste and energy consumption, helping businesses reduce their environmental footprint while maximizing their productivity.Furthermore, Pp Extruder Machine is dedicated to staying abreast of the latest industry trends and technological advancements. The company continually upgrades its equipment and processes to incorporate the latest innovations, ensuring that its clients have access to the most advanced extrusion solutions available. By staying at the forefront of technology, Pp Extruder Machine enables businesses to stay competitive and meet the evolving demands of the market.Looking ahead, Pp Extruder Machine is poised to further expand its presence in the global market. The company is committed to forging partnerships with businesses worldwide and providing them with top-of-the-line extrusion machines that deliver exceptional performance and value. With its solid track record, dedication to excellence, and forward-looking approach, Pp Extruder Machine is well-positioned to maintain its leadership in the industry and continue driving innovation and progress.In conclusion, Pp Extruder Machine has established itself as a leading provider of high-quality extrusion solutions. With its focus on innovation, customer satisfaction, environmental sustainability, and technological advancement, the company has set the bar high for manufacturing excellence. Businesses in search of reliable and efficient extrusion machines need look no further than Pp Extruder Machine for all their needs.

Benefits and Uses of Small Twin Screw Extruders

Title: Small Twin Screw Extruder: Revolutionizing Polymer Processing Industry Introduction:In today's fast-paced industrial world, efficient and effective machinery plays a crucial role in driving growth and innovation. Addressing the increasing demand for polymer processing with enhanced productivity and versatility, {Company Name}'s Small Twin Screw Extruder is transforming the industry. This state-of-the-art machine combines cutting-edge technology with superior build quality, taking polymer processing to new heights. Advancement in Polymer Processing:Polymer processing technology has evolved significantly over the years, with extrusion playing a key role in manufacturing various products. The Small Twin Screw Extruder by {Company Name} exemplifies the latest advancements in this field. As the demand for polymer-based applications continues to grow in sectors such as packaging, construction, and automotive, the extruder offers unparalleled efficiency, precision, and flexibility.Key Features and Benefits:1. Compact Design: The Small Twin Screw Extruder boasts a compact structure, making it suitable for use in constrained spaces. Its ergonomic design ensures ease of use and maintenance, saving both time and effort.2. High Efficiency: The extruder is equipped with twin screws that operate in perfect sync, facilitating a highly efficient and streamlined extrusion process. This results in improved productivity and reduced energy consumption, ultimately leading to cost savings for manufacturers.3. Versatility: From simple polymer compounding to intricate product development, the Small Twin Screw Extruder caters to a diverse range of applications. Its adjustable parameters allow manufacturers to customize the machine's settings to meet their specific requirements, enabling enhanced product development and quality control.4. Superior Mixing Capability: The machine's twin screws provide exceptional mixing and dispersion of various additives, fillers, and additives, ensuring homogeneous product output. This feature enables manufacturers to achieve consistent quality and reduces material waste, resulting in significant savings.5. Enhanced Processing Control: The extruder's advanced control systems, coupled with user-friendly interfaces, empower operators to monitor and adjust process parameters with ease. Real-time data display and analysis enable quick decision-making, reducing downtime and enhancing overall efficiency.Industry Impact:The introduction of {Company Name}'s Small Twin Screw Extruder has had a profound impact on the polymer processing industry. The machine's advanced capabilities have paved the way for innovation and efficiency, transforming the way manufacturers approach polymer-based applications. With reduced production costs, enhanced product quality, and increased overall productivity, manufacturers can now meet the evolving demands of their customers more effectively.Future Prospects:The Small Twin Screw Extruder by {Company Name} is not just a testament to the present advancements in the polymer processing industry but also an indicator of its future potential. Continuous research and development efforts by {Company Name} promise further improvements in machine design, performance, and versatility. As the industry continues to demand optimized processes, customization, and material compatibility, the Small Twin Screw Extruder offers exciting possibilities for manufacturers.Conclusion:{Company Name}'s Small Twin Screw Extruder has revolutionized the polymer processing industry by combining state-of-the-art technology with unparalleled efficiency and versatility. With its compact design, high efficiency, superior mixing capability, and enhanced processing control, the extruder empowers manufacturers to produce high-quality polymer-based products while optimizing costs and resources. As the demand for polymer applications grows, {Company Name} remains committed to pushing the boundaries of innovation, driving the industry forward.

How Hdpe Pipe Extrusion Can Benefit Your Business

[Hdpe Pipe Extrusion] Company Leads the Industry in Producing High-Quality Pipes[Company Name], a leading manufacturer in the field of HDPE pipe extrusion, has been making waves in the industry with its cutting-edge technology and commitment to producing top-quality products. With a focus on innovation and efficiency, [Company Name] has established itself as a key player in the market, providing high-quality HDPE pipes for a wide range of applications.The company's dedication to producing superior HDPE pipes stems from its state-of-the-art manufacturing facilities and a team of highly skilled professionals. By leveraging advanced extrusion technology, [Company Name] is able to consistently deliver products that meet and exceed industry standards. This has earned the company a reputation for reliability and excellence in the market.One of the key factors that sets [Company Name] apart from its competitors is its commitment to sustainability. The company adheres to strict environmental guidelines and invests in eco-friendly production processes, making it a responsible choice for customers who value sustainability and environmental stewardship. This dedication to sustainability is reflected in the quality of [Company Name]'s HDPE pipes, which are known for their durability and longevity.With a focus on delivering value to its customers, [Company Name] takes a customer-centric approach to its operations. The company offers a wide range of HDPE pipes in various sizes and specifications to cater to the diverse needs of its customers. Whether it's for water distribution, gas conveyance, or industrial applications, [Company Name] has the expertise and capabilities to provide tailored solutions for its clients.Furthermore, [Company Name] has built a solid track record of delivering projects on time and within budget, earning the trust of its customers and partners. This reliability and consistency have proven to be key factors in the company's success and growth in the industry.In addition to its focus on product quality and customer satisfaction, [Company Name] is also known for its commitment to research and development. The company continuously invests in exploring new technologies and materials to further enhance its product offerings. By staying at the forefront of innovation, [Company Name] is able to anticipate market trends and meet the evolving needs of its customers.As a testament to its success and impact on the industry, [Company Name] has received accolades and certifications for its manufacturing and quality standards. These recognitions serve as a testament to the company's dedication to excellence and its position as a leader in the HDPE pipe extrusion industry.Looking ahead, [Company Name] is poised to continue its growth trajectory and expand its presence in both local and international markets. Through strategic partnerships and investments in infrastructure, the company aims to further solidify its position as a preferred supplier of high-quality HDPE pipes.In conclusion, [Company Name] has demonstrated its leadership in the field of HDPE pipe extrusion through its commitment to innovation, sustainability, and customer satisfaction. With a strong focus on quality and reliability, the company has earned the trust and respect of its customers, setting the standard for excellence in the industry. As [Company Name] continues to push the boundaries of what's possible, it is well-positioned to shape the future of HDPE pipe extrusion and make a lasting impact on the market.

Efficient Agricultural Film Recycling Machine for Sustainable Waste Management

Agricultural Film Recycling Machine Revolutionizes Plastic Waste ManagementThe global issue of plastic waste and environmental pollution has led to the development of innovative recycling solutions to minimize the impact of plastic materials on the planet. One of the leading contributors to plastic waste is agricultural film, used extensively in the farming industry for purposes such as mulching, greenhouse covering, and silage protection. To address this pressing issue, a groundbreaking Agricultural Film Recycling Machine has been developed by a pioneering company specializing in environmental sustainability and waste management solutions. This innovative machine offers a sustainable and efficient method for recycling agricultural films, thereby reducing the environmental impact of plastic waste within the agriculture sector.The company behind this game-changing technology is dedicated to being at the forefront of sustainable development, with a strong focus on circular economy principles and reducing the environmental footprint of plastic materials. With a mission to empower industries to embrace a more sustainable approach to plastic usage, the company has invested heavily in research and development to create cutting-edge recycling equipment that meets the specific needs of the agriculture industry.The Agricultural Film Recycling Machine is designed to process a wide range of agricultural films, including but not limited to polyethylene (PE) films, polypropylene (PP) films, and biodegradable films. This advanced recycling system utilizes state-of-the-art technology to efficiently remove contaminants, such as soil, sand, and organic residues, from the agricultural films, ensuring a high-quality output that meets strict recycling standards.The machine incorporates a series of innovative processes, including washing, shredding, and extrusion, to transform used agricultural films into high-quality recycled plastic pellets. These pellets can then be used as raw materials for the production of new agricultural films or other plastic products, closing the loop on the plastic waste cycle and minimizing the need for virgin plastic materials.While traditional methods of agricultural film disposal often result in landfilling or incineration, the Agricultural Film Recycling Machine offers a more sustainable and environmentally friendly alternative. By repurposing used agricultural films into valuable recycled materials, this technology not only reduces the reliance on virgin plastics but also significantly lowers the carbon footprint associated with plastic production.Moreover, the implementation of the Agricultural Film Recycling Machine promotes a circular economy approach within the agriculture industry, where used plastic materials are reintegrated into the production cycle, thus conserving valuable resources and minimizing waste. This not only benefits the environment but also contributes to the economic sustainability of the agriculture sector by creating a closed-loop system for plastic materials.In addition to its environmental and economic advantages, the Agricultural Film Recycling Machine aligns with the global efforts to combat plastic pollution and achieve a more sustainable future. As countries worldwide are increasingly adopting stringent regulations and targets for plastic waste management, this innovative recycling technology offers a practical solution for the agriculture industry to meet these requirements and demonstrate environmental responsibility.The company's commitment to promoting sustainable agricultural practices and environmental stewardship through the development of the Agricultural Film Recycling Machine underscores its dedication to driving positive change in the industry. By enabling farmers and agricultural businesses to responsibly manage their plastic waste and minimize their environmental impact, this technology represents a significant step towards a more sustainable and circular agricultural ecosystem.As the world continues to grapple with the challenges of plastic pollution and environmental degradation, innovative solutions such as the Agricultural Film Recycling Machine play a crucial role in mitigating these issues and fostering a more sustainable future for the agriculture industry and the planet as a whole. With its transformative capabilities and environmental benefits, this cutting-edge recycling technology is set to revolutionize the management of agricultural film waste and pave the way for a more sustainable and circular economy.

Industry Insights: Unveiling the Secrets behind the Corrugated Tube Manufacturing Process

Title: Innovative Corrugated Tube Machine Revolutionizes Manufacturing ProcessIntroduction:In an effort to revolutionize the manufacturing process and meet the growing demands of the industry, an innovative corrugated tube machine has been introduced by a leading technology company. This cutting-edge machine, which combines state-of-the-art technology and advanced design features, promises to improve efficiency, productivity, and quality in the production of corrugated tubes. This article will delve into the features of the machine, highlighting its potential impact on the manufacturing sector.1. Enhanced Efficiency:The new corrugated tube machine boasts several key features that optimize production efficiency. Equipped with an automated system, it eliminates manual intervention and reduces dependency on human labor. This not only accelerates the production process but also minimizes the chances of errors or defects. Additionally, the machine employs real-time monitoring and data analysis, allowing for quick identification and resolution of any production issues, resulting in enhanced operational effectiveness.2. Advanced Design Features:A critical aspect of the corrugated tube machine is its advanced design features. The machine integrates intelligent software that enables seamless control and coordination of various manufacturing components. This smart technology ensures precise formation of corrugations, resulting in high-quality, uniform tubes. The machine's ability to handle different sizes and types of materials further enhances its versatility, catering to diverse industrial requirements.3. Improved Productivity:The introduction of the corrugated tube machine signifies a substantial increase in productivity. Traditional methods often suffer from bottlenecks and delays due to manual intervention, resulting in a slower manufacturing process. However, with the new machine's automated features, operators can now produce a greater number of tubes in a shorter span of time. The elimination of manual labor-intensive tasks allows workers to focus on other value-added activities, thereby boosting overall productivity.4. Quality Assurance:Through rigorous testing and quality control measures, the corrugated tube machine ensures consistent and high-quality output. Precision engineering and intelligent software work in tandem to maintain accurate dimensions, minimizing deviations in tube specifications. The machine's real-time monitoring system enables operators to promptly identify any production irregularities, facilitating immediate corrective actions. This dedication to quality assurance helps businesses gain customer confidence and maintain their market reputation.5. Adaptability and Customization:The versatility of the corrugated tube machine enables customization to meet various industry requirements. With the ability to process different materials, sizes, and thicknesses, manufacturers can cater to a wide range of applications, including the automotive, construction, and electrical industries. This adaptability will spur innovation within these sectors, empowering businesses to explore new possibilities, improve product quality, and reduce costs.Conclusion:The integration of an advanced corrugated tube machine into the manufacturing process marks a significant step forward in the industry. With its enhanced efficiency, advanced design features, improved productivity, and quality assurance capabilities, this machine holds great potential to reshape the manufacturing sector. By harnessing innovative technologies, businesses can now streamline their operations, reduce human intervention, and offer superior products to their customers. The introduction of this game-changing machine underscores the ever-evolving nature of manufacturing and highlights the importance of staying at the forefront of technological advancements.

Affordable Prices for Grinders: Find the Best Deals Now

Grinder Price, a rapidly growing company in the home appliance industry, has been making headlines for its innovative and high-quality products. The company has built a strong reputation for offering reliable and durable grinders that are designed to cater to the various needs of consumers. With an extensive range of products and a commitment to customer satisfaction, Grinder Price has established itself as a leading player in the market.The company’s commitment to delivering top-notch grinders at competitive prices has earned it a loyal customer base and glowing reviews from industry experts. Grinder Price’s dedication to quality and innovation has set it apart from its competitors, making it a go-to choice for consumers looking for reliable and efficient home appliances.One of the key factors behind Grinder Price’s success is its relentless focus on research and development. The company invests heavily in the development of new technologies and features that enhance the performance and longevity of its grinders. By staying at the forefront of innovation, Grinder Price continues to push the boundaries of what is possible in the home appliance industry, setting new standards for quality and functionality.In addition to its dedication to product development, Grinder Price also places a strong emphasis on customer satisfaction. The company’s customer service team is highly trained and dedicated to providing support and assistance to consumers, ensuring that every customer has a positive experience with their products. This commitment to excellence has helped Grinder Price build a reputation for reliability and trustworthiness, further solidifying its position in the industry.Furthermore, Grinder Price’s commitment to sustainability sets it apart as a responsible and forward-thinking company. The company prioritizes the use of eco-friendly materials and production methods, minimizing its environmental impact while still delivering top-quality products. This focus on sustainability has resonated with consumers who are increasingly conscious of the environmental impact of their purchasing decisions, further strengthening Grinder Price’s appeal in the market.Despite the challenges posed by the global pandemic, Grinder Price has continued to thrive and expand its reach. The company’s online presence has enabled it to reach a wider audience and connect with consumers around the world. By leveraging the power of e-commerce and digital marketing, Grinder Price has been able to increase its market share and solidify its position as a global leader in the home appliance industry.Looking ahead, Grinder Price is poised for even greater success as it continues to push the boundaries of innovation and quality in the home appliance industry. With its unwavering commitment to excellence, sustainability, and customer satisfaction, Grinder Price is well-positioned to maintain its strong growth trajectory and remain a top choice for consumers in search of high-quality grinders.In conclusion, Grinder Price has established itself as a leading player in the home appliance industry, known for its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, sustainability, and digital marketing, Grinder Price is well-positioned for continued success and growth in the years to come. As the company continues to expand its reach and its product offerings, consumers can expect to see even more exciting and reliable grinders from Grinder Price in the future.

The Undisclosed Expenses Associated with Twin Screw Extruder Acquisition

Title: Affordable Twin Screw Extruder Solutions Revolutionize the Manufacturing IndustryIntroduction:In today's competitive manufacturing landscape, companies across various industries are constantly exploring cost-effective solutions to enhance their production processes. One such solution gaining increasing popularity is the Twin Screw Extruder. With its ability to efficiently process a wide range of materials, this machinery is enabling businesses to achieve higher productivity and quality standards while streamlining expenses. This article delves into the innovation behind Twin Screw Extruders and the significant cost reductions they offer, making them an indispensable asset for manufacturers worldwide.1. The Twin Screw Extruder Advantage:Twin Screw Extruders are versatile machines used in various industries, including plastics, food processing, pharmaceuticals, and chemical manufacturing. These extruders consist of two intermeshing screws that operate side by side within a barrel. When the material enters the extruder, the rotating screws move it forward, subjecting it to mechanical and thermal forces that facilitate mixing, melting, and homogenizing.The twin screw configuration offers many advantages over single screw extruders, including higher throughput rates, improved mixing capabilities, and enhanced control over material properties. This versatility allows manufacturers to work with a broader range of materials, opening up new possibilities for product development.2. New Cost-Effective Solutions:Traditionally, accessing Twin Screw Extruders came with a hefty price tag, often limiting their widespread adoption among small and medium enterprises. However, recent technological advancements and market competition have resulted in more affordable, yet equally efficient, alternatives.Thanks to innovative engineering and streamlined manufacturing processes, several companies, including industry leaders and newer entrants, are offering cost-effective Twin Screw Extruder solutions, efficiently meeting the needs of manufacturers at a reduced investment. These affordable alternatives do not compromise on performance, reliability, or quality, allowing businesses of all sizes to leverage the benefits of this technology.3. Enhanced Performance and Efficiency:The incorporation of advanced technology in new-generation Twin Screw Extruders has significantly improved their performance and efficiency. These machines are engineered to handle a broader range of materials, including polymer blends, resins, and additives, with precision and consistency.The enhanced process control mechanisms, efficient energy consumption, and optimized screw design of these extruders ensure higher throughput rates and improved product quality. This results in reduced wastage, enhanced product consistency, and lower production costs for manufacturers. Additionally, the ability of Twin Screw Extruders to accommodate materials with a wide range of viscosities and melt temperatures further adds to their efficiency.4. Cost Reduction Strategies:The affordability of Twin Screw Extruders can be attributed to various factors. One such factor is the improved manufacturing process, where advancements in production techniques and standardized components have reduced both material and labor costs. Additionally, manufacturers are focused on simplifying maintenance routines, thereby reducing operational expenses over the machine's lifetime.Moreover, increased market competition has prompted suppliers to offer more cost-friendly alternatives without compromising on quality. This intense competition has driven innovation and rethinking of traditional design practices, leading to more streamlined, efficient, and reasonably priced Twin Screw Extruder models.5. Impact on Industries:The broader accessibility to affordable Twin Screw Extruders is revolutionizing several industries, allowing manufacturers to enhance their processes, develop new products, and stay competitive in the market. With reduced investment costs, more companies can now embrace these extruders to meet growing consumer demands and market challenges.The plastics industry, for instance, benefits from the twin screw technology by efficiently processing a wide range of polymers, resulting in high-quality and consistent end products. Similarly, in food processing, the extruders' ability to blend, cook, and shape ingredients enables manufacturers to create a vast array of products, from breakfast cereals to functional snacks.Conclusion:The availability of affordable Twin Screw Extruders is transforming the manufacturing industry by enabling businesses of all sizes to streamline their processes and enhance productivity. With improved performance, efficiency, and reduced investment costs, these extruders are becoming an indispensable asset for manufacturers worldwide. As competition continues to spur innovation in this field, the future holds promising advancements in Twin Screw Extruder technology, paving the way for further cost efficiencies and enhanced manufacturing capabilities.

Efficient Extruder Pelletizer: Enhancing Productivity and Quality

Extruder Pelletizer Revolutionizes Plastic Manufacturing ProcessThe global plastic industry is constantly evolving, driven by the demand for innovation, sustainability, and efficiency. In line with this, a leading manufacturer has recently unveiled their latest technological breakthrough – an advanced extruder pelletizer. This state-of-the-art equipment is set to revolutionize the plastic manufacturing process, offering numerous benefits to businesses operating in the industry.The extruder pelletizer, developed by a renowned company with years of experience in the field, is designed to streamline the production of plastic pellets. These pellets, which serve as the raw material for various plastic products, are crucial for manufacturers across multiple sectors, including packaging, construction, automotive, and healthcare.One of the key features that sets this extruder pelletizer apart from conventional models is its enhanced precision and efficiency. With cutting-edge technology and intelligent systems, it allows for precise control of the pelletizing process, resulting in consistent pellet size, shape, and quality. This level of precision is crucial for manufacturers who require uniform pellets in order to maintain their product's structural integrity and functionality.This new extruder pelletizer also offers a high degree of customization, catering to the unique needs of different manufacturers. It can handle a wide range of polymer materials, including polyethylene, polypropylene, polystyrene, and polyvinyl chloride, among others. With adjustable settings, manufacturers can easily adapt the equipment to meet their specific production requirements, whether it be for rigid or flexible plastics, high or low throughput rates, or different pellet sizes.Furthermore, the advanced design of this extruder pelletizer ensures optimal energy efficiency. It incorporates innovative features that minimize energy consumption, such as efficient heating systems and optimized motor controls. This not only helps to reduce the carbon footprint of plastic manufacturing processes but also translates into cost savings for businesses in the long run. By investing in this cutting-edge equipment, manufacturers can improve their overall sustainability profile and contribute to a greener future.Additionally, this extruder pelletizer boasts an intuitive user interface and advanced automation capabilities. With a user-friendly touchscreen display and remote monitoring options, operators can easily control and monitor the equipment's performance from a centralized location. Real-time data and analytics enable proactive maintenance, reducing downtime and enhancing productivity. This level of automation ensures an efficient and streamlined manufacturing process, allowing manufacturers to meet customer demands more effectively.Being a global leader in plastic manufacturing equipment, the company behind this revolutionary extruder pelletizer has a strong focus on research and development. Their expertise and commitment to innovation have allowed them to introduce cutting-edge solutions that empower manufacturers to stay ahead in an increasingly competitive industry. With a global network of service and support, they ensure that customers receive the necessary assistance and expertise to maximize the performance of their equipment.In conclusion, the introduction of the advanced extruder pelletizer marks a significant development in the plastic manufacturing industry. This state-of-the-art equipment offers precision, efficiency, customization, energy efficiency, user-friendliness, and automation, all of which contribute to streamlining the manufacturing process. As manufacturers strive to meet the demands of a rapidly changing market, investing in this revolutionary technology can unlock new opportunities, improve product quality, and drive sustainable growth.

Innovative Plastic Mixer Machine for Efficient Mixing

Plastic Mixer Machine Revolutionizes the Manufacturing IndustryIn the fast-paced world of manufacturing, efficiency and innovation are key to staying ahead of the competition. Companies are constantly looking for cutting-edge technology to streamline their production processes and improve the quality of their products. With this in mind, the introduction of the Plastic Mixer Machine by {Company Name} has been a game-changer for the industry.The Plastic Mixer Machine is a state-of-the-art piece of equipment that revolutionizes the way plastics are mixed and blended. With its advanced technology and precision engineering, the machine is able to mix different types of plastics with unparalleled accuracy and consistency. This not only ensures a higher quality end product, but also significantly reduces waste and production costs.{Company Name} has been a leader in the manufacturing industry for over 20 years, and their commitment to innovation and excellence is evident in the development of the Plastic Mixer Machine. The company's team of expert engineers and designers have worked tirelessly to create a machine that is not only highly efficient, but also easy to use and maintain. As a result, the Plastic Mixer Machine has quickly become a must-have piece of equipment for manufacturers around the world.One of the key features of the Plastic Mixer Machine is its versatility. It is capable of mixing a wide range of plastics, including polyethylene, polypropylene, PVC, and PET, among others. This means that manufacturers no longer have to invest in multiple machines for different types of plastics, saving both space and money. The machine's advanced control system allows for precise control over the mixing process, ensuring that the desired blend is achieved every time.In addition to its impressive mixing capabilities, the Plastic Mixer Machine is also designed with efficiency in mind. Its high-speed mixing technology allows for faster production times, while its energy-efficient design helps to reduce overall power consumption. This not only benefits the environment, but also translates to significant cost savings for manufacturers.Furthermore, the machine's user-friendly interface and intuitive controls make it easy for operators to monitor and adjust the mixing process as needed. This ensures a smooth and seamless production process, with minimal downtime and maximum output. The machine is also equipped with advanced safety features to protect operators and prevent accidents in the workplace.Over the years, {Company Name} has built a reputation for delivering top-quality products and exceptional customer service. The introduction of the Plastic Mixer Machine has only reinforced this reputation, as the machine has been met with rave reviews from manufacturers who have incorporated it into their production lines."We are thrilled with the performance of the Plastic Mixer Machine," says a satisfied customer. "It has completely transformed our production process and has allowed us to achieve a level of consistency and quality that we never thought possible. It truly is a game-changer for our business."As the manufacturing industry continues to evolve, the demand for cutting-edge technology like the Plastic Mixer Machine will only continue to grow. {Company Name} remains committed to staying at the forefront of this evolution, and will undoubtedly continue to push the boundaries of innovation in the years to come. With its revolutionary Plastic Mixer Machine, the company has cemented its position as a leader in the industry, and is poised to shape the future of manufacturing for years to come.