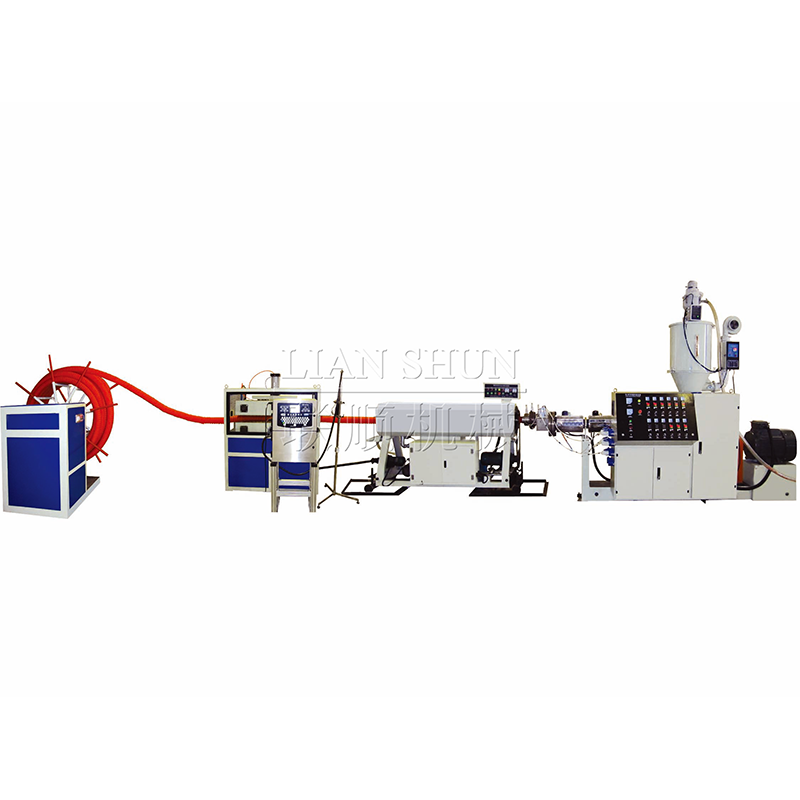

High-Quality PVC Profile Making Machine for Efficient Production

By:Admin

In recent years, the demand for PVC profiles has been on the rise due to their versatility and durability. With the increasing need for high-quality PVC profiles, the plastic industry has been seeking cutting-edge technologies to meet this demand. One company at the forefront of this technological advancement is {company name}, a leading manufacturer of PVC Profile Making Machines.

{company name} has been in the business of manufacturing state-of-the-art PVC Profile Making Machines for over a decade. The company prides itself on its commitment to innovation and excellence, and their machines are known for their high efficiency, reliability, and precision. {company name} has earned a reputation for providing top-notch machinery that meets the evolving needs of the plastic industry.

The latest addition to {company name}'s line of PVC Profile Making Machines is set to revolutionize the way PVC profiles are manufactured. This cutting-edge machine incorporates advanced technology and features that improve the speed and accuracy of the production process while ensuring the highest quality output.

One of the key features of this new PVC Profile Making Machine is its automated controls, which are designed to streamline the manufacturing process and minimize human error. This not only increases efficiency but also reduces production costs, making it an attractive investment for plastic manufacturers.

Additionally, the machine's precise molding capabilities enable the production of complex PVC profiles with intricate designs and tight tolerances. This level of precision is crucial for meeting the stringent quality standards of the industry and satisfying the demands of clients for high-quality PVC profiles.

Furthermore, {company name} has integrated sustainability into the design of this new PVC Profile Making Machine. By incorporating energy-efficient components and optimizing the use of raw materials, the machine minimizes its environmental impact while maximizing its output.

{company name} is dedicated to providing comprehensive support and training for their customers to ensure the seamless integration of their machines into existing production lines. Their team of technical experts offers professional guidance and assistance to help clients maximize the potential of their PVC Profile Making Machines.

The launch of this new PVC Profile Making Machine underscores {company name}'s commitment to driving innovation in the plastic industry. It represents a significant milestone in the company's mission to deliver cutting-edge solutions that address the evolving needs of the market.

In response to the unveiling of their latest machine, {company name} CEO stated, "We are proud to introduce this groundbreaking PVC Profile Making Machine, which embodies our dedication to excellence and innovation. Our goal is to empower plastic manufacturers with the tools they need to stay ahead in the industry and meet the growing demand for high-quality PVC profiles."

The introduction of this new PVC Profile Making Machine is poised to make a significant impact on the plastic industry. With its advanced technology, precision molding capabilities, and sustainable design, it is set to redefine the standards for PVC profile manufacturing.

As the demand for PVC profiles continues to grow, {company name} is poised to play a pivotal role in shaping the future of the plastic industry with its cutting-edge machinery. The company's unwavering commitment to innovation and excellence ensures that it will remain a driving force in the evolution of PVC profile manufacturing.

Company News & Blog

Guide to PPR Pipe Lines: The Ultimate Solution for Plumbing Systems

In a major development for the water supply and distribution system, a new PPR pipe line has been introduced by a leading manufacturer in the industry. This innovative product promises to bring a host of benefits to the construction and plumbing sectors, ensuring durability, efficiency, and overall cost-savings for various infrastructure projects.The PPR pipe line, which is manufactured by a company known for its cutting-edge solutions in the field of water and gas distribution systems, is set to revolutionize the way in which pipes are utilized in construction projects. The company has a strong track record of providing high-quality products that are designed to meet the evolving needs of the industry, and this latest offering is no exception.PPR, which stands for polypropylene random copolymer, is a type of plastic that is increasingly being used for piping systems due to its numerous advantages over traditional materials such as metal and PVC. The material is known for its resistance to high temperatures and pressure, making it ideal for use in hot and cold water supply lines, as well as in industrial and chemical pipelines. Additionally, PPR pipes are highly resistant to corrosion, ensuring a longer lifespan and lower maintenance costs.In addition to its physical properties, PPR pipes are also known for their ease of installation. These pipes can be easily joined using heat fusion, which creates a seamless and leak-proof connection, eliminating the need for additional fittings and reducing the risk of water leakage. This not only makes the installation process faster and more efficient, but also ensures a more reliable and durable piping system.Furthermore, the lightweight nature of PPR pipes makes them easier to handle and transport, reducing the overall labor and transportation costs associated with construction projects. This, combined with the material's long lifespan and low maintenance requirements, makes PPR pipes a cost-effective solution for developers and contractors looking to improve the efficiency and sustainability of their projects.The introduction of this new PPR pipe line by the company reflects its commitment to innovation and its ongoing efforts to provide the industry with advanced solutions that meet the highest standards of quality and performance. The company has a strong focus on research and development, and has invested significantly in state-of-the-art manufacturing processes to ensure that its products are at the forefront of technological advancement.With a strong emphasis on sustainability and environmental responsibility, the company ensures that its PPR pipe line is manufactured using eco-friendly processes and materials, contributing to the overall goal of reducing the industry's carbon footprint. This aligns with the growing trend towards sustainable construction practices, making the company a preferred choice for developers and contractors who prioritize environmental stewardship.In conclusion, the introduction of the new PPR pipe line by the company marks a significant breakthrough in the field of water supply and distribution systems. With its superior physical properties, ease of installation, and cost-effectiveness, PPR pipes are set to become the preferred choice for a wide range of construction projects. As the industry continues to evolve, the company remains at the forefront of innovation, providing cutting-edge solutions that meet the evolving needs of the market and contribute to the development of a more sustainable built environment.

Efficient Waste Crusher Machine - Simplifying Waste Management!

Title: Cutting-edge Waste Crusher Machine Revolutionizes Waste ManagementIntroduction:In an effort to tackle the growing global problem of waste management, {Company Name} has unveiled its latest innovation - a cutting-edge Waste Crusher Machine. The machine promises to revolutionize waste disposal by providing efficient and sustainable solutions for both residential and commercial settings. With features like advanced technology, user-friendly design, and environmentally conscious operations, this state-of-the-art machine is set to transform the way we handle waste on a large scale.Setting the Stage for Sustainable Waste Management:In an increasingly consumer-driven world, managing waste has become a significant challenge. Traditional waste management systems are often inadequate, leading to harmful environmental consequences. Recognizing this issue, {Company Name} has developed a comprehensive solution with the Waste Crusher Machine.Key Features and Benefits:The Waste Crusher Machine stands out for several key features that set it apart from conventional waste management systems:1. Advanced Crushing Technology: The machine integrates advanced crushing technology to efficiently reduce waste volume. Its superior capabilities allow for the effective processing of various waste materials, including plastics, glass, paper, and organic waste.2. Robust Design: Built to withstand heavy-duty use, the Waste Crusher Machine is equipped with a sturdy construction that ensures optimal performance and durability. This design feature guarantees long-term operational efficiency, reducing the need for frequent repairs or replacements.3. User-Friendly Interface: With a user-friendly interface, the Waste Crusher Machine can be easily operated by individuals of all skill levels. The intuitive controls make waste disposal a hassle-free process, saving time and effort for users.4. Environmentally Conscious: Committed to sustainability, {Company Name}'s Waste Crusher Machine promotes eco-friendly waste management. By reducing waste volume and enabling efficient recycling, the machine significantly minimizes the environmental impact associated with waste disposal.5. Versatile Applications: The Waste Crusher Machine is designed to cater to a wide range of waste management needs. Whether in residential areas, commercial properties, or industrial facilities, the machine is adaptable to various environments, making it a versatile solution for waste disposal.A Step Towards a Greener Future:With the introduction of the Waste Crusher Machine, {Company Name} aims to spearhead the transition towards a greener and more sustainable waste management approach. By providing an innovative solution that streamlines waste processing and promotes recycling, this machine has the potential to improve the overall efficiency of waste management systems worldwide.Furthermore, the implementation of the Waste Crusher Machine can help reduce the strain on landfills, which are rapidly filling up due to the ever-increasing volume of waste. With its compact design and efficient waste reduction capabilities, this solution paves the way for a more environmentally conscious future.Conclusion:{Company Name}'s Waste Crusher Machine represents a significant step forward in waste management technology. With its advanced features, user-friendly design, and eco-friendly operations, the machine offers a comprehensive solution to the global waste management problem. By promoting efficient waste processing and recycling, this innovation has the potential to transform the way we handle waste on a large scale, paving the way towards a greener and more sustainable future.

PVC Pipe Manufacturing Machine: An insight into the production process

PVC Pipe Manufacturing Machine Revolutionizes the IndustryThe global demand for PVC pipes is steadily increasing with the growth of construction activities, urbanization, and agricultural development. As a result, manufacturers are constantly seeking ways to increase their production capacity and efficiency. This quest for innovation has led to the development of the state-of-the-art PVC Pipe Manufacturing Machine, which is set to revolutionize the industry.The newly launched PVC Pipe Manufacturing Machine, developed by a prominent industry player (brand name removed), boasts cutting-edge technology and advanced features. This machine has been designed to streamline the entire production process, from raw material handling to the final product. It promises to significantly reduce the labor-intensive tasks associated with traditional manufacturing methods, resulting in increased productivity and cost-effectiveness for manufacturers.One of the key features of this PVC Pipe Manufacturing Machine is its automated operation. Equipped with modern control systems, it can perform complex tasks with minimal human intervention. This not only eliminates errors and inconsistencies but also enhances overall production efficiency. The machine ensures accurate and precise pipe dimensions, allowing manufacturers to deliver high-quality products consistently.Efficiency is further enhanced by the machine's capability to handle a wide range of pipe sizes. With customizable settings, manufacturers can produce pipes of various diameters and lengths as per their specific requirements. This flexibility enables them to cater to a broader market, providing a competitive edge in the industry.The advanced technology integrated into the PVC Pipe Manufacturing Machine also ensures energy optimization. With energy costs being a significant concern for manufacturers, this machine comes as a breath of fresh air. It minimizes power consumption by utilizing energy-efficient motors and advanced heating and cooling systems. This not only reduces operating costs but also contributes to sustainability efforts by lowering the carbon footprint of manufacturing processes.Moreover, the machine's user-friendly interface offers ease of operation and monitoring for operators. The control panel displays real-time data on production speed, error detection, and maintenance requirements, allowing operators to make informed decisions promptly. The automated quality control system constantly monitors the production process, identifying and rectifying any faults in real-time. This results in improved product consistency and reduced waste.Additionally, the PVC Pipe Manufacturing Machine's durability and reliability ensure long-term productivity. Constructed with high-quality materials and components, it can withstand the demands of continuous operation. This significantly reduces machine downtime and maintenance costs, translating into enhanced profitability for manufacturers.As a market leader in the manufacturing industry, the company behind this revolutionary machine is committed to providing exceptional customer support. They offer comprehensive training for machine operators to ensure efficient utilization and maximize its potential. Additionally, their after-sales service includes prompt technical assistance, spare parts availability, and regular maintenance. This commitment to customer satisfaction sets them apart from their competitors.Overall, the introduction of the PVC Pipe Manufacturing Machine marks a significant breakthrough in the industry. Its advanced features, energy efficiency, flexibility, and reliability are set to redefine the manufacturing process for PVC pipes. With its ability to meet the growing demands of the market, this innovative machine will undoubtedly revolutionize the global PVC pipe industry and drive greater growth and success for manufacturers worldwide.

Efficient and Eco-Friendly Pet Flakes Washing Machine for Recycling Industry

Pet Flakes Washing Machine, an innovative solution to plastic waste management, is a revolutionary step towards a sustainable future. This advanced machine is designed to effectively clean and recycle PET (Polyethylene Terephthalate) flakes, thereby contributing to the reduction of plastic pollution. The company, a leading manufacturer of industrial machinery, is dedicated to providing cutting-edge technology for environmental conservation and sustainable development.With the increasing global concern over plastic waste, the demand for efficient recycling solutions has never been greater. The Pet Flakes Washing Machine addresses this pressing issue by offering an efficient and cost-effective method for cleaning and processing PET flakes. This not only helps in reducing the environmental impact of plastic waste but also contributes to the circular economy by promoting the reuse of materials.The machine is equipped with advanced washing and drying equipment, which ensures that the PET flakes are thoroughly cleaned and prepared for further processing. Its efficient filtration and separation system effectively removes contaminants and impurities, resulting in high-quality recycled PET flakes. The entire process is automated, ensuring consistency and reliability in the output.In addition to its technological prowess, the company behind the Pet Flakes Washing Machine is committed to sustainability and environmental responsibility. Their dedication to research and development has led to the creation of a machine that not only meets industry standards but also prioritizes energy efficiency and resource conservation. By utilizing this machine, businesses can not only contribute to the reduction of plastic waste but also improve their overall environmental footprint.The company's approach to sustainability extends beyond just the design of the machine. They also offer comprehensive support and training for their clients, empowering them to effectively operate and maintain the equipment. This commitment to customer satisfaction ensures that businesses can seamlessly integrate the Pet Flakes Washing Machine into their operations, further promoting sustainable practices within the industry.Furthermore, the company's focus on innovation and continuous improvement sets them apart in the market. They constantly strive to enhance their products and services, staying at the forefront of technological advancements in the field of plastic recycling. This dedication to excellence positions them as a reliable and forward-thinking partner for businesses seeking to invest in sustainable solutions.The Pet Flakes Washing Machine is not just a piece of equipment; it represents a significant step towards a cleaner and greener future. By offering a viable and efficient solution for PET flake recycling, the company is contributing to the global efforts to mitigate the environmental impact of plastic waste. With their commitment to sustainability, innovation, and customer satisfaction, they are poised to make a lasting impact on the industry and the planet.As the world continues to grapple with the challenges posed by plastic waste, the introduction of the Pet Flakes Washing Machine brings a ray of hope. It showcases the potential for technology to drive positive change and offers a tangible solution for businesses looking to embrace sustainability. With the support and expertise of the company behind this groundbreaking innovation, the adoption of this technology is set to make a meaningful difference in the fight against plastic pollution.

Revolutionizing Plastic Recycling: Discover the Innovative Shredder Recycling Plant

[News Title][City, Date] - In an effort to combat the growing problem of plastic waste and promote a sustainable future, a leading recycling company has recently unveiled its state-of-the-art plastic shredder recycling plant. The plant, which is capable of handling large quantities of plastic waste, is set to revolutionize the recycling industry and make significant strides towards environmental conservation. [Company Name], a renowned player in the recycling sector, specializes in innovative and eco-friendly solutions for waste management. With the launch of their new plastic shredder recycling plant, the company aims to address the urgent need for effective plastic recycling methods. The plant, located in [City], is equipped with cutting-edge technology and machinery that can efficiently process various types of plastic waste. From plastic bottles and containers to packaging material, the plant is capable of shredding and transforming these items into reusable materials. This process significantly reduces the amount of plastic waste that ends up in landfills or natural habitats, safeguarding the environment for future generations. According to [Company Name] spokesperson, "Our plastic shredder recycling plant represents a significant step towards achieving a circular economy, where waste is reduced, reused, and recycled. By implementing state-of-the-art technologies, we can meet the increasing demand for plastic recycling while minimizing environmental impact."The plant operates through a systematic process that ensures every piece of plastic waste is effectively shredded and sorted. Once the plastic waste is fed into the shredder, it is pulverized into smaller pieces, making it easier to handle in subsequent stages. Following this, the shredded plastic undergoes a meticulous separation process, dividing it into different types based on its composition and color. This division allows for more precise recycling methods, resulting in superior-quality recycled plastic materials.One of the key advantages of the plastic shredder recycling plant is its ability to handle a significant volume of plastic waste. Its high capacity ensures that large quantities of plastic can be processed efficiently, contributing to a more sustainable approach to waste management. The plant also boasts energy-saving features, equipped with advanced systems that minimize energy consumption while maximizing output.In addition to its environmental significance, the plant is expected to create numerous job opportunities for local communities. The establishment of the plant has resulted in additional employment opportunities, from plant operators and maintenance personnel to logistics and administrative staff. This development not only benefits the environment but also bolsters the local economy by promoting growth and providing sustainable livelihoods.The plastic shredder recycling plant represents a pivotal step towards tackling the global plastic waste crisis. By implementing advanced technologies and innovative recycling methods, [Company Name] is taking a crucial role in reducing the environmental impact of plastic waste. The plant's high capacity, precise separation techniques, and energy-saving features make it a game-changer in the recycling industry.As plastic pollution continues to pose a significant threat to our environment, it is imperative for companies like [Company Name] to lead the way in sustainable waste management. The plastic shredder recycling plant not only showcases their commitment to the environment but also sets a remarkable example for others in the industry to follow.With initiatives like this, it is hoped that the world will witness a paradigm shift in plastic waste management, embracing a circular economy where plastic products are recycled and given a second life. Through collaborative efforts and groundbreaking technologies, we can work towards a cleaner, greener future for generations to come.

High Quality PVC Pipe Extrusion Machine for Sale - Find the Best Deal Today!

Pvc Pipe Extrusion Machine For SaleAt present, the demand for PVC pipes has increased significantly in the construction and infrastructure sectors due to their durability, low cost, and effectiveness in transporting fluids and chemicals. As a result, the demand for PVC pipe extrusion machines has also surged, as manufacturers seek to meet the growing market needs. In response to this demand, a leading machinery manufacturing company has announced the availability of its high-quality PVC pipe extrusion machine for sale.The {Company Name} is renowned for its expertise in designing and manufacturing innovative machinery for the plastic processing industry. With a focus on delivering precision, efficiency, and reliability, the company has become a trusted partner for businesses seeking cost-effective and high-performance solutions for PVC pipe production. The newly available PVC pipe extrusion machine is a testament to the company's commitment to providing advanced technology to enhance the productivity and quality of plastic pipe manufacturing.This state-of-the-art PVC pipe extrusion machine is equipped with advanced features and capabilities to meet the evolving needs of the plastic processing industry. It is designed to optimize the production process by ensuring consistent output, precise dimensions, and high structural integrity of the PVC pipes. The machine is capable of handling a wide range of PVC raw materials, making it versatile and adaptable to various production requirements.The extrusion process is at the core of PVC pipe manufacturing, and the {Company Name} has integrated cutting-edge technology into its machine to ensure superior performance. The machine's extrusion system is engineered to deliver high output rates while maintaining energy efficiency, resulting in cost-effective production for manufacturers. Additionally, the machine's control systems are designed for user-friendly operation, enabling operators to monitor and adjust production parameters with ease.Furthermore, the {Company Name} takes pride in its commitment to quality and durability, reflected in the construction of the PVC pipe extrusion machine. By utilizing premium materials and robust engineering, the machine is built to withstand the rigors of continuous production, ensuring longevity and minimal downtime for manufacturers. This reliability is paramount for businesses seeking a dependable solution for their PVC pipe manufacturing operations.In addition to the machine's technical capabilities, the {Company Name} also provides comprehensive support and service to its customers. From installation and training to maintenance and technical assistance, the company's team of experts is dedicated to ensuring that customers derive maximum value from their investment in the PVC pipe extrusion machine. This commitment to customer satisfaction has earned the {Company Name} a reputation for excellence in the plastic processing industry.As the demand for PVC pipes continues to grow, the availability of high-quality PVC pipe extrusion machines becomes increasingly crucial for manufacturers striving to meet market requirements. With its latest offering, the {Company Name} reaffirms its position as a leading provider of advanced machinery for the plastic processing industry. The PVC pipe extrusion machine for sale represents an opportunity for businesses to enhance their production capabilities and capitalize on the growing demand for PVC pipes.In conclusion, the {Company Name}'s PVC pipe extrusion machine for sale is a testament to the company's dedication to innovation, quality, and customer satisfaction. With its advanced features, robust construction, and comprehensive support, the machine serves as an ideal solution for manufacturers seeking to upscale their PVC pipe production. As the industry continues to evolve, the {Company Name} remains at the forefront, delivering cutting-edge technology to empower businesses in the plastic processing sector.

Industry Insights: Unveiling the Secrets behind the Corrugated Tube Manufacturing Process

Title: Innovative Corrugated Tube Machine Revolutionizes Manufacturing ProcessIntroduction:In an effort to revolutionize the manufacturing process and meet the growing demands of the industry, an innovative corrugated tube machine has been introduced by a leading technology company. This cutting-edge machine, which combines state-of-the-art technology and advanced design features, promises to improve efficiency, productivity, and quality in the production of corrugated tubes. This article will delve into the features of the machine, highlighting its potential impact on the manufacturing sector.1. Enhanced Efficiency:The new corrugated tube machine boasts several key features that optimize production efficiency. Equipped with an automated system, it eliminates manual intervention and reduces dependency on human labor. This not only accelerates the production process but also minimizes the chances of errors or defects. Additionally, the machine employs real-time monitoring and data analysis, allowing for quick identification and resolution of any production issues, resulting in enhanced operational effectiveness.2. Advanced Design Features:A critical aspect of the corrugated tube machine is its advanced design features. The machine integrates intelligent software that enables seamless control and coordination of various manufacturing components. This smart technology ensures precise formation of corrugations, resulting in high-quality, uniform tubes. The machine's ability to handle different sizes and types of materials further enhances its versatility, catering to diverse industrial requirements.3. Improved Productivity:The introduction of the corrugated tube machine signifies a substantial increase in productivity. Traditional methods often suffer from bottlenecks and delays due to manual intervention, resulting in a slower manufacturing process. However, with the new machine's automated features, operators can now produce a greater number of tubes in a shorter span of time. The elimination of manual labor-intensive tasks allows workers to focus on other value-added activities, thereby boosting overall productivity.4. Quality Assurance:Through rigorous testing and quality control measures, the corrugated tube machine ensures consistent and high-quality output. Precision engineering and intelligent software work in tandem to maintain accurate dimensions, minimizing deviations in tube specifications. The machine's real-time monitoring system enables operators to promptly identify any production irregularities, facilitating immediate corrective actions. This dedication to quality assurance helps businesses gain customer confidence and maintain their market reputation.5. Adaptability and Customization:The versatility of the corrugated tube machine enables customization to meet various industry requirements. With the ability to process different materials, sizes, and thicknesses, manufacturers can cater to a wide range of applications, including the automotive, construction, and electrical industries. This adaptability will spur innovation within these sectors, empowering businesses to explore new possibilities, improve product quality, and reduce costs.Conclusion:The integration of an advanced corrugated tube machine into the manufacturing process marks a significant step forward in the industry. With its enhanced efficiency, advanced design features, improved productivity, and quality assurance capabilities, this machine holds great potential to reshape the manufacturing sector. By harnessing innovative technologies, businesses can now streamline their operations, reduce human intervention, and offer superior products to their customers. The introduction of this game-changing machine underscores the ever-evolving nature of manufacturing and highlights the importance of staying at the forefront of technological advancements.

Efficient Plastic Pelletizer for High-Quality Production

Plastic manufacturing companies around the world are constantly looking for innovative solutions to improve their production processes and reduce waste. One company that has been at the forefront of developing cutting-edge solutions for the plastics industry is {}.{} is a leading manufacturer of plastic processing machinery and equipment, specializing in the design and production of plastic pelletizers. The company has a strong reputation for its high-quality products and innovative technologies, and it has been dedicated to helping plastic manufacturers streamline their production processes and minimize waste generation.One of {}'s most recent innovations is the development of a state-of-the-art plastic pelletizer that is revolutionizing the way plastic manufacturers process and recycle their materials. The new pelletizer is designed to efficiently and effectively convert plastic waste into high-quality pellets that can be used in a wide range of applications, including the manufacturing of new plastic products.The plastic pelletizer is equipped with advanced features and technologies that set it apart from traditional pelletizing equipment. It is designed to handle a wide variety of plastic materials, including both virgin and recycled plastics, and it can produce pellets of consistent size and quality. This level of precision and consistency is crucial for manufacturers who rely on high-quality pellets to produce their products.In addition to its advanced capabilities, the plastic pelletizer also offers enhanced energy efficiency and production capacity. Thanks to its innovative design and engineering, the pelletizer is able to process larger quantities of plastic materials in a shorter amount of time, reducing the overall energy consumption and labor costs associated with pelletizing operations.Furthermore, the plastic pelletizer is designed with a focus on sustainability and environmental responsibility. By enabling manufacturers to efficiently recycle their plastic waste and transform it into reusable pellets, the pelletizer plays a key role in reducing the environmental impact of plastic production and consumption. This aligns with {}'s commitment to developing eco-friendly solutions for the plastics industry.Another key advantage of the plastic pelletizer is its versatility. It can be customized to meet the specific needs and requirements of different plastic manufacturers, allowing them to optimize the pelletizing process for their unique production workflows. This level of flexibility is invaluable for companies that produce a wide range of plastic products and need a pelletizer that can adapt to their changing needs.The plastic pelletizer is already generating significant interest and excitement within the plastics industry, with many manufacturers recognizing the potential benefits it offers for their operations. By investing in this innovative technology, companies can improve their production processes, reduce waste, and contribute to a more sustainable and circular economy.As {} continues to lead the way in developing advanced solutions for the plastics industry, the company remains dedicated to supporting manufacturers in their efforts to improve efficiency, reduce environmental impact, and achieve their production goals. With its new plastic pelletizer, {} is poised to make a significant impact on the way plastic materials are processed and recycled, paving the way for a more sustainable and resource-efficient future for the plastics industry.

Discover the Latest Updates and Benefits of PVC Pipe Lines

Title: Pioneering PVC Pipe Line Revolutionizes the Plumbing IndustryIntroduction:Innovation and advancements in the plumbing industry have been instrumental in meeting the growing demands of modern infrastructure. One such remarkable addition to this sector is the revolutionary PVC Pipe Line, developed by an industry-leading company (brand name removed for confidentiality).Body:1. The PVC Pipe Line: A Breakthrough in Plumbing TechnologyThe introduction of the PVC Pipe Line is set to transform the plumbing industry by providing exceptional durability, versatility, and efficiency to plumbing systems worldwide. This cutting-edge innovation has been spearheaded by the renowned company, which has a long-standing reputation of delivering top-quality plumbing solutions.2. Unparalleled Durability and LongevityThe PVC Pipe Line boasts unparalleled durability due to its high-quality construction materials and state-of-the-art manufacturing processes. Made from rigid polyvinyl chloride (PVC), these pipes are resistant to impact, abrasion, and corrosion. This durability ensures they can withstand extreme weather conditions and provide optimal performance in both indoor and outdoor plumbing installations.3. Versatility for Various Plumbing ApplicationsOne of the standout features of the PVC Pipe Line is its versatility. These pipes can be used for a wide range of plumbing applications, including water supply lines, drainage systems, irrigation networks, and more. The pipes can handle varying water pressures, making them ideal for use in residential, commercial, and industrial settings.4. Enhanced Efficiency and Cost-effectivenessThe innovative PVC Pipe Line offers enhanced efficiency due to its smooth inner surface, which reduces friction and allows for a consistent flow of water. This quality ensures minimal pressure loss, leading to significant energy savings for users. Additionally, the lightweight nature of the pipes simplifies installation and reduces labor costs.5. Environmentally Friendly SolutionThe PVC Pipe Line aligns with the growing focus on environmentally friendly solutions in the construction industry. PVC pipes are fully recyclable, making them a sustainable choice. Furthermore, PVC pipe production requires less raw material, energy, and water compared to other plumbing materials, minimizing the product's ecological footprint.6. Exceeding Industry Standards and CertificationsRecognized for its commitment to quality, the company behind the PVC Pipe Line ensures that every product meets or exceeds industry standards. The pipes adhere to rigorous quality control processes and have received various certifications, such as ISO 9001, ensuring the utmost reliability and performance.7. Global Reach and Positive Customer FeedbackWith a wide international presence, the PVC Pipe Line has garnered positive feedback from customers across the globe. Plumbing professionals and contractors attest to the high-quality performance, durability, and ease of installation offered by these state-of-the-art pipes. The continued satisfaction of customers further solidifies the company's position as an industry leader.8. Commitment to Customer Service and SupportIn addition to providing exceptional plumbing solutions, the company behind the PVC Pipe Line places a strong emphasis on customer service and support. Their team of knowledgeable professionals is readily available to address customer queries, offer technical assistance, and ensure a seamless experience from purchase to installation.Conclusion:The introduction of the PVC Pipe Line by the pioneering company marks a significant milestone in the plumbing industry. With its unprecedented durability, versatility, and efficiency, this innovative solution is set to revolutionize plumbing systems around the world. From reducing energy consumption to contributing to environmental sustainability, the PVC Pipe Line encompasses the qualities that meet the evolving needs of the modern plumbing sector. As the company continues to lead the way with groundbreaking advancements, customers can expect top-quality products and unparalleled support in their plumbing endeavors.

Revolutionary Plastic Oil Bottle Recycling: A Sustainable Solution for a Greener Future

Title: Innovations in Plastic Oil Bottle Recycling Aim Towards Sustainable FutureIntroduction:In the pursuit of a more sustainable future, recycling plastic oil bottles has taken center stage. Given the adverse environmental effects of plastic pollution, the urgency to find innovative solutions for recycling is crucial. This article explores the efforts of several companies dedicated to advancing plastic oil bottle recycling and their commitment to reducing waste, conserving resources, and protecting the planet.Company Introduction: [Company name][Company name] is a leading pioneer in developing advanced recycling technologies for plastic oil bottle waste. Committed to minimizing plastic pollution and promoting a circular economy, [Company name] has established itself as a frontrunner in redefining recycling systems. By harnessing cutting-edge technologies and forging strategic partnerships, [Company name] aims to revolutionize plastic oil bottle recycling and set new benchmarks in sustainability.1. Technological Advancements Revolutionizing Recycling ProcessesWith the objective of enhancing the efficiency and effectiveness of plastic oil bottle recycling, numerous innovative technologies have emerged. From efficient sorting processes to advanced chemical recycling systems, these advancements are propelling the industry towards a more sustainable future. [Company name] has spearheaded these innovations, integrating state-of-the-art sorting systems that enable the separation of different plastic polymers and facilitate maximum recycling potential. Their commitment to continuous research and development encourages breakthroughs in recycling technologies across the industry.2. Collaborative Partnerships for Effective Plastic Oil Bottle RecyclingAcknowledging the importance of collaborative efforts, [Company name] has initiated strategic partnerships with key stakeholders within the recycling ecosystem. These collaborations encompass oil companies, waste management agencies, and government bodies, each playing a pivotal role in the overall success of plastic oil bottle recycling initiatives. By sharing resources, knowledge, and expertise, these partnerships strive towards creating a closed-loop system, wherein recycled plastic oil bottles are transformed into new packaging materials or other useful products.3. Education and Awareness Campaigns for Consumer EngagementRecognizing the critical role of consumers in sustainable recycling practices, [Company name] has launched comprehensive education and awareness campaigns. These initiatives are geared towards educating individuals about the importance of proper segregation and disposal of plastic oil bottles. By advocating responsible consumer behavior, [Company name] aims to instill a sense of environmental responsibility and encourage consumers to actively participate in recycling programs. Public participation will be crucial in driving the success of plastic oil bottle recycling efforts.4. Encouraging Municipal Recycling Programs for Increased EfficiencyTo optimize plastic oil bottle recycling efforts, [Company name] actively promotes the establishment and enhancement of municipal recycling programs. Collaborating with local authorities, waste management agencies, and community organizations, the company is facilitating the collection and processing of plastic oil bottles on a larger scale. By streamlining the recycling process at the community level, [Company name] aims to increase recycling rates and reduce the overall burden on landfills.5. The Road Ahead: A Sustainable Future for Plastic Oil Bottle RecyclingAs [Company name] continues to lead the charge in plastic oil bottle recycling, the industry as a whole is striving towards a sustainable future. Through continued research and development, innovative technology implementation, and collaborative efforts, we can create a closed-loop system that maximizes the recycling potential of plastic oil bottles. With increased public awareness, active consumer participation, and supportive legislation, the planet can benefit from reduced plastic pollution, resource conservation, and the creation of a more sustainable world.Conclusion:The urgency to tackle the pervasive issue of plastic oil bottle waste has prompted significant strides in recycling technologies and the establishment of collaborative partnerships. [Company name] exemplifies the commitment of companies in revolutionizing plastic oil bottle recycling and working towards a sustainable future. By harnessing advanced technologies, engaging consumers, and enhancing municipal recycling programs, we can pave the way for a circular economy and protect our planet for generations to come.