Efficient HDPE Bottle Washing Line for Recycling Process

By:Admin

The HDPE bottle washing line is equipped with cutting-edge technology that allows for the efficient and effective cleaning of a wide range of HDPE bottles. This includes bottles used for packaging a variety of products, such as detergents, shampoos, and household cleaners. The line is designed to remove contaminants and impurities from the bottles, resulting in high-quality, clean HDPE material that can be used for the production of new plastic products.

"We are thrilled to introduce this new HDPE bottle washing line to our facility," said [Company Name]'s CEO. "At [Company Name], we are dedicated to finding innovative solutions for recycling and sustainability, and this new line will allow us to further advance our efforts in reducing the environmental impact of plastic waste."

The launch of the HDPE bottle washing line aligns with [Company Name]'s broader mission to promote a circular economy by recycling and reusing plastic materials. By investing in advanced recycling technologies, [Company Name] aims to minimize the environmental impact of plastic waste and contribute to a more sustainable future.

In addition to the environmental benefits, the new HDPE bottle washing line will also enhance [Company Name]'s ability to meet the growing demand for high-quality recycled plastic materials. This is particularly important as more and more companies are seeking sustainable alternatives to virgin plastic for their manufacturing needs.

The installation of the HDPE bottle washing line is just one of many initiatives [Company Name] has undertaken to improve its recycling capabilities. The company has also implemented a comprehensive quality control process to ensure that the recycled HDPE material meets the highest standards for purity and consistency.

Furthermore, [Company Name] is committed to working with its customers and partners to promote the use of recycled plastic materials. By offering a reliable supply of clean, high-quality HDPE material, the company aims to support the transition to a more sustainable and circular economy.

"We believe that recycling plays a crucial role in reducing the environmental impact of plastic waste," said [Company Name]'s CEO. "With the introduction of the new HDPE bottle washing line, we are excited to strengthen our position as a leader in the recycling industry and contribute to a more sustainable future."

As [Company Name] continues to expand its recycling capabilities, the company remains focused on driving positive change in the industry. Through its investments in advanced technologies and commitment to sustainability, [Company Name] is well-positioned to make a meaningful impact in the ongoing effort to reduce plastic waste and promote a circular economy.

The launch of the HDPE bottle washing line represents a significant milestone for [Company Name], and the company looks forward to the opportunities it will create for sustainable innovation and environmental progress. With its continued dedication to recycling and sustainability, [Company Name] is poised to lead the way towards a more circular and responsible approach to plastic usage.

Company News & Blog

High-Quality PVC Ceiling Machine for Sale - Find Out More!

PVC Ceiling Machine Revolutionizes Manufacturing ProcessThe manufacturing industry has undergone a significant transformation with the introduction of the innovative PVC Ceiling Machine from a leading company in the field. This state-of-the-art machine has redefined the production process for PVC ceiling materials, streamlining operations and enhancing efficiency for manufacturers around the world.With a focus on delivering advanced manufacturing solutions, the company has developed a cutting-edge PVC Ceiling Machine that is designed to meet the growing demands of the industry. By leveraging the latest technologies and engineering expertise, the machine offers a range of capabilities that have set a new standard for PVC ceiling production.One of the key features of the PVC Ceiling Machine is its high-speed production capabilities, allowing manufacturers to significantly increase their output without compromising on quality. This has proven to be a game-changer for businesses looking to meet the growing market demand for PVC ceiling materials, empowering them to scale their operations and gain a competitive edge.Furthermore, the machine's precision engineering and automated functions have resulted in a more efficient and consistent production process. From material feeding and mixing to shaping and cutting, the PVC Ceiling Machine offers unparalleled accuracy and reliability, ensuring that every product meets the highest standards of quality.In addition to its performance capabilities, the PVC Ceiling Machine also offers a level of versatility that is unmatched in the industry. With the ability to produce a wide range of PVC ceiling products in various sizes, shapes, and designs, manufacturers can cater to diverse customer needs and market preferences with ease.The company behind this revolutionary machine is renowned for its commitment to innovation and customer satisfaction. With a strong track record of delivering cutting-edge solutions and unrivaled technical support, they have established themselves as a trusted partner for manufacturers seeking to elevate their production capabilities.It is worth noting that the PVC Ceiling Machine is not only a technological breakthrough but also a testament to the company's dedication to sustainability. Through its efficient design and energy-saving features, the machine promotes eco-friendly manufacturing practices, aligning with the global push for greener and more responsible production processes.As the manufacturing industry continues to evolve, the introduction of the PVC Ceiling Machine has made a significant impact, paving the way for a new era of efficiency, productivity, and quality in PVC ceiling production. With its advanced features, unmatched performance, and the backing of a reputable company, this machine has become a game-changer for manufacturers worldwide.In conclusion, the PVC Ceiling Machine from {} is poised to revolutionize the manufacturing process for PVC ceiling materials, offering a compelling combination of speed, precision, versatility, and sustainability. As manufacturers embrace this innovative solution, they are well-positioned to meet the demands of a dynamic market and achieve new levels of success in their operations.

Affordable Recycling Machines for Sale: Find the Best Prices Today

[Company Introduction]{Company Name} is a leading provider of waste management and recycling solutions. With a focus on sustainability and environmental responsibility, {Company Name} offers a range of products and services aimed at reducing the impact of waste on the planet. The company's mission is to create a more sustainable future by providing innovative and effective recycling solutions for businesses and communities.[Recycling Machines Price]In line with their commitment to environmental sustainability, {Company Name} has recently announced the launch of their latest recycling machine, designed to make recycling more convenient and efficient for consumers. The new machine, equipped with state-of-the-art technology, simplifies the recycling process, making it easier for individuals to contribute to a more sustainable future.At an introductory price of $5000, the recycling machine is a cost-effective investment for businesses and organizations looking to incorporate sustainable practices into their operations. With its compact design and user-friendly interface, the machine is suitable for a wide range of settings, including offices, schools, public spaces, and more. The affordable price point makes it an accessible option for businesses of all sizes, furthering {Company Name}'s mission to make recycling a viable and realistic option for all.The new recycling machine comes equipped with advanced sorting capabilities, allowing it to effectively separate various types of recyclable materials. This feature not only streamlines the recycling process but also ensures that materials are properly sorted and prepared for further processing, contributing to the overall efficiency of the recycling chain. Additionally, the machine includes a user-friendly interface, making it easy for individuals to operate and engage with the recycling process.{Company Name} has emphasized that the affordability of the new recycling machine does not compromise its quality or performance. Built to the highest standards, the machine is durable and reliable, capable of withstanding regular use in high-traffic environments. Furthermore, {Company Name} offers comprehensive support and maintenance services, ensuring that the machine continues to operate at peak performance over time.The unveiling of the new recycling machine is a significant step forward for {Company Name} in their efforts to promote sustainable waste management practices. By making recycling more accessible and convenient, the company aims to encourage greater participation in recycling initiatives, ultimately reducing the amount of waste that ends up in landfills and incinerators. This, in turn, contributes to the conservation of natural resources and the mitigation of environmental pollution.The launch of the new recycling machine is a testament to {Company Name}'s dedication to innovation and sustainability. By offering a high-quality, affordable solution for recycling, the company is empowering businesses and communities to take proactive steps towards a greener, more sustainable future. As awareness of the environmental impact of waste continues to grow, the demand for accessible and effective recycling solutions is on the rise, and {Company Name} is poised to meet this demand with their latest offering.{Company Name} remains committed to advancing the cause of environmental sustainability through their range of products and services. The new recycling machine, with its competitive price and cutting-edge features, is a testament to the company's ongoing efforts to make a positive impact on the planet. As businesses and individuals increasingly prioritize sustainability, {Company Name} is well-positioned to lead the way in providing practical, effective solutions for waste management and recycling.

Ultimate Guide to PVC Profile Extrusion: Everything You Need to Know

PVC Profile Extrusion: Revolutionizing the Building IndustryPVC profile extrusion is a process that has been rapidly gaining popularity in the building industry. This innovative technology allows for the creation of high-quality, durable, and cost-effective PVC profiles that are used in a wide range of applications, from windows and doors to electrical conduits and plumbing fixtures.One company that has been leading the way in PVC profile extrusion is {}. With years of experience and expertise in the industry, {} has been at the forefront of developing and implementing advanced extrusion technologies to meet the growing demand for high-performance PVC profiles.The company's state-of-the-art manufacturing facility is equipped with the latest extrusion machinery and tools, allowing them to produce a wide variety of PVC profiles with precision and efficiency. From custom-designed profiles to standard shapes and sizes, {} has the capability to cater to the diverse needs of their clients.One of the key advantages of PVC profile extrusion is the ability to create profiles that offer superior strength, durability, and resistance to harsh environmental conditions. This makes PVC profiles an ideal choice for outdoor applications, where they can withstand exposure to sunlight, moisture, and extreme temperatures without deteriorating.In addition to their durability, PVC profiles are also lightweight, making them easy to handle and install. This, combined with their low maintenance requirements, makes PVC profiles a cost-effective solution for builders and contractors looking to optimize their construction projects.Furthermore, PVC profiles are highly customizable, allowing for the incorporation of various design elements, colors, and finishes. This versatility makes them an attractive choice for architects and designers seeking to achieve a specific aesthetic appeal in their projects.Another significant advantage of PVC profile extrusion is the material's excellent thermal and sound insulation properties. This makes PVC profiles an energy-efficient option for building applications, helping to reduce heating and cooling costs while providing a comfortable indoor environment.Additionally, PVC profiles are inherently resistant to corrosion, rot, and decay, making them a long-lasting solution for both residential and commercial projects. This durability ensures that PVC profiles maintain their structural integrity over time, contributing to the overall longevity of buildings and infrastructure.As environmental sustainability becomes increasingly important in the construction industry, PVC profile extrusion offers a greener alternative to traditional building materials. PVC profiles can be recycled and repurposed, reducing the ecological footprint of construction projects and contributing to a more circular economy.With the versatility, durability, and sustainability of PVC profile extrusion, it is no surprise that this innovative technology has been embraced by manufacturers and builders worldwide. From enhancing the performance of building materials to driving architectural innovation, PVC profiles are revolutionizing the way we build and design the world around us.As {}. continues to evolve and expand their PVC profile extrusion capabilities, they remain committed to delivering the highest quality products and services to their clients. With a focus on innovation, efficiency, and customer satisfaction, {}. is poised to shape the future of the building industry with their cutting-edge PVC profile extrusion technology.

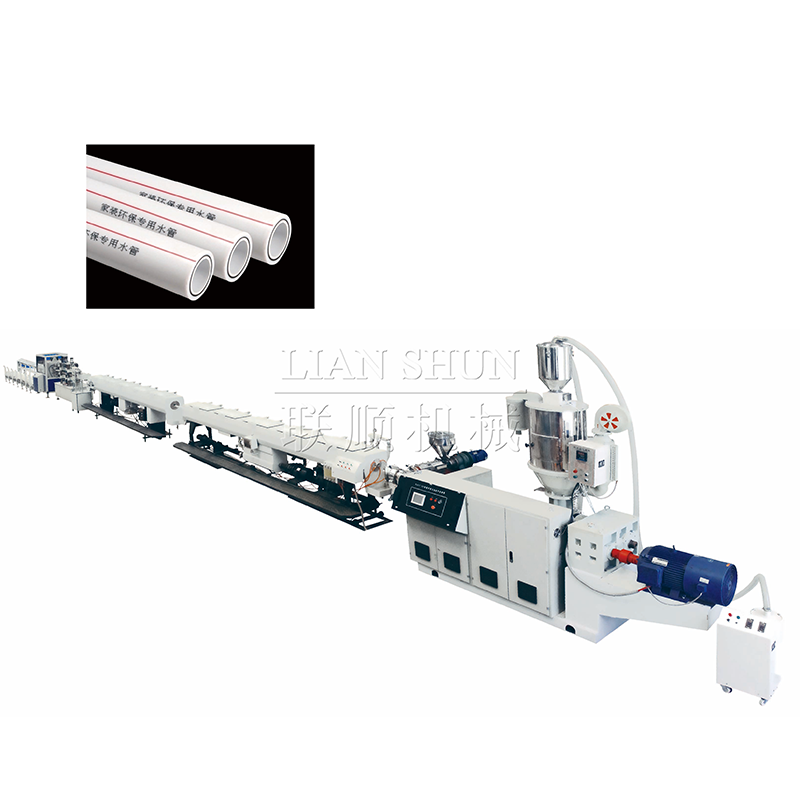

Durable and Versatile PPR Pipe Line for Various Applications

Ppr Pipe Line Company recently announced the launch of its new line of PPR pipes, designed to meet the growing demand for high-quality and durable piping solutions in the construction industry. This latest addition to the company's product portfolio is expected to further strengthen their position as a leading provider of innovative and reliable piping systems.The new PPR pipes are manufactured using the latest technology and highest quality materials, ensuring superior performance and durability. They are designed to be resistant to corrosion, chemicals, and high temperatures, making them suitable for a wide range of applications, including hot and cold water supply, heating systems, and industrial piping.Ppr Pipe Line Company has been a trusted name in the industry for many years, known for their commitment to delivering top-notch products and exceptional customer service. They have built a strong reputation for their reliability, expertise, and dedication to meeting the needs of their clients.The company's comprehensive range of piping solutions includes PPR pipes, fittings, and accessories, all of which are engineered to meet the highest standards of quality and safety. Their products are widely used in residential, commercial, and industrial construction projects, and are preferred by contractors and engineers for their ease of installation and long-term performance.In addition to their high-quality products, Ppr Pipe Line Company also offers a range of services to support their clients throughout the project lifecycle. Their team of experienced engineers and technical experts provide assistance with product selection, design, installation, and maintenance, ensuring that their clients receive the most suitable solutions for their specific requirements.The launch of the new PPR pipes demonstrates Ppr Pipe Line Company's commitment to innovation and continuous improvement. By staying at the forefront of technological advancements and industry trends, they are able to develop products that meet the evolving needs of their clients and offer sustainable solutions for the future.“We are excited to introduce our new line of PPR pipes, which have been meticulously engineered to deliver exceptional performance and reliability,” said the spokesperson for Ppr Pipe Line Company. “As a company, we are constantly striving to raise the bar and set new standards in the industry. Our latest offering is a testament to our dedication to providing the best possible solutions for our customers.”Ppr Pipe Line Company's dedication to quality and innovation has earned them a loyal customer base and a strong market presence. Their products are widely recognized for their superior quality, durability, and performance, and are trusted by construction professionals around the world.With the launch of the new PPR pipes, Ppr Pipe Line Company looks set to further solidify their position as a leading provider of cutting-edge piping solutions. Their commitment to excellence, combined with their extensive industry expertise and customer-centric approach, makes them a reliable partner for any construction project.

High-Quality Pp Pipe Machine: Latest Updates and Industry Insights

A leading manufacturer in the plastic machinery industry, {Company Name} has recently launched its latest innovation, the PP Pipe Machine. This state-of-the-art machine is designed to meet the increasing demand for high-quality polypropylene pipes in various industrial and commercial applications.The PP Pipe Machine is the result of {Company Name}'s extensive research and development efforts, aimed at providing its customers with advanced and efficient solutions for pipe production. With a focus on precision engineering and technological innovation, the machine offers a range of features that set it apart in the market.One of the key advantages of the PP Pipe Machine is its ability to produce pipes with superior strength and durability. The machine is equipped with advanced extrusion technology that ensures the uniform distribution of material, resulting in pipes that are resistant to corrosion, heat, and chemical damage. This makes the pipes suitable for a wide range of applications, including water supply, drainage, irrigation, and industrial fluid transport.In addition to its exceptional product quality, the PP Pipe Machine also boasts high production efficiency. With a fully automated operation and precision control systems, the machine is able to maintain a high production speed while ensuring consistent pipe dimensions and wall thickness. This not only increases the output capacity but also reduces production costs for manufacturers, making it a highly cost-effective solution for pipe production.Furthermore, the PP Pipe Machine is designed for versatility, allowing for the production of pipes in various sizes and specifications. This flexibility enables manufacturers to cater to a diverse range of customer requirements, while also adapting to evolving market demands. Additionally, the machine is equipped with user-friendly interfaces and controls, making it easy for operators to set up, monitor, and adjust the production parameters as needed.With its cutting-edge technology and superior performance, the PP Pipe Machine is poised to make a significant impact in the plastic pipe manufacturing industry. {Company Name} is confident that the machine will not only meet the current needs of its customers but also drive innovation and growth in the industry as a whole.{Company Name} is a globally recognized leader in the design and manufacture of plastic machinery, with a strong focus on delivering high-quality, reliable, and efficient solutions to its customers. With a proven track record of innovation and excellence, the company has established itself as a trusted partner for manufacturers across various industries, offering a comprehensive range of plastic machinery including extrusion lines, injection molding machines, and auxiliary equipment.In addition to its advanced technology and product quality, {Company Name} places a strong emphasis on customer satisfaction and support. The company is committed to providing comprehensive pre-sales and after-sales services, including technical consultation, equipment installation and commissioning, and ongoing maintenance and support. This approach has earned {Company Name} a reputation for reliability and trustworthiness, further solidifying its position as a leading supplier in the plastic machinery market.Looking ahead, {Company Name} remains dedicated to driving innovation and excellence in the plastic machinery industry, and the launch of the PP Pipe Machine is a testament to the company's ongoing commitment to meeting the evolving needs of its customers and the industry as a whole. With its cutting-edge technology and superior performance, the PP Pipe Machine is set to elevate the standards of pipe production, offering manufacturers a reliable and efficient solution for meeting the growing demand for high-quality polypropylene pipes.

Bottle Crusher Machine: Revolutionizing Waste Management with Advanced Technology

Title: Revolutionary Bottle Crusher Machine Transforms Recycling IndustryIntroduction (approximately 100 words):In an era where sustainability and environmental responsibility are more crucial than ever, ABC Company is leading the way with their revolutionary Bottle Crusher Machine. The cutting-edge technology behind this innovative solution is set to transform the recycling industry by streamlining the process of plastic bottle disposal. By eliminating the need for manual sorting and reducing the volume of bottles considerably, this machine is set to greatly enhance recycling efforts and decrease the carbon footprint associated with plastic waste.Body:1. Overcoming Recycling Challenges (approximately 200 words):The Bottle Crusher Machine by ABC Company is designed to tackle the challenges that traditional recycling methods face head-on. Manual sorting of plastic bottles is a labor-intensive and time-consuming process, often leading to inefficiencies and increased costs. Moreover, large volumes of bottles fill up landfill sites rapidly, causing environmental concerns. To tackle these challenges, ABC Company has developed a state-of-the-art solution. By employing advanced technology such as artificial intelligence and machine learning algorithms, the Bottle Crusher Machine can quickly and accurately sort different types of plastic bottles, significantly reducing manual labor and increasing operational efficiency.2. Key Features and Functionality (approximately 200 words):The Bottle Crusher Machine incorporates several key features that set it apart from traditional recycling methods. One such feature is its ability to automatically crush and compact plastic bottles of various shapes and sizes. This process ultimately results in reduced storage requirements, enabling recycling centers to maximize their available space.Moreover, the machine is equipped with advanced sensors and algorithms that enable it to differentiate between different types of plastic bottles. By sorting these bottles based on their composition, the machine ensures that they are sent for appropriate recycling or disposal processes. This innovative functionality helps significantly reduce contamination in recycling streams, resulting in higher-quality recycled materials.3. Positive Environmental Impact (approximately 200 words):The Bottle Crusher Machine's introduction is expected to have a significant positive impact on reducing plastic waste and promoting sustainable practices. With the ability to compact bottles, the machine helps minimize the amount of space required for storage and transportation of plastic waste. This ultimately reduces the carbon footprint associated with plastic disposal.In addition, by streamlining the recycling process and enhancing efficiency, the machine encourages more people to recycle their plastic bottles. With increased convenience and reduced effort required on the part of consumers, the rate of recycling is likely to rise considerably. This, in turn, will lead to a decreased reliance on landfill sites, thereby preserving natural resources and mitigating the adverse effects of plastic waste on the environment.Conclusion (approximately 100 words):The introduction of ABC Company's Bottle Crusher Machine marks a significant step forward in revolutionizing the recycling industry. By combining cutting-edge technology, efficient sorting algorithms, and a commitment to sustainability, this machine is set to transform plastic bottle disposal. With the potential to increase recycling rates, reduce contamination, and streamline operations, this revolutionary device paves the way for a more sustainable future. ABC Company's continued dedication to driving positive environmental change positions them at the forefront of the recycling industry, working towards a cleaner and greener planet.

Powerful Shredder Machine: A Must-Have Tool for Efficient Waste Management

[Company Name] Unveils Cutting-Edge Shredder Machine to Revolutionize Waste Management Industry[City, Date] - [Company Name], a leading manufacturer of innovative machinery and equipment, has revealed its latest breakthrough in the field of waste management technology – the [Model Name] Shredder Machine. This cutting-edge piece of equipment promises to revolutionize the way businesses and industries dispose of their waste, offering a more efficient, cost-effective, and environmentally-friendly solution.The [Model Name] Shredder Machine is the result of years of research and development, aimed at addressing the growing challenges of waste management in today's fast-paced and increasingly industrialized world. With its advanced features and robust design, this shredder is set to make a significant impact on various sectors, including manufacturing, recycling, waste disposal, and more.One of the key features of the [Model Name] Shredder Machine is its high-capacity shredding capability, which allows it to process a wide range of materials with ease, including plastic, paper, metal, and even electronic waste. This versatility makes it an invaluable asset for businesses looking to streamline their waste management processes and reduce their environmental footprint.In addition to its impressive shredding capabilities, the [Model Name] Shredder Machine is also equipped with state-of-the-art safety features, ensuring optimal protection for operators and minimizing the risk of accidents in the workplace. This prioritization of safety aligns with [Company Name]'s commitment to delivering not only cutting-edge technology but also ensuring the well-being of its customers and their employees.Furthermore, the [Model Name] Shredder Machine is designed with efficiency in mind, featuring a user-friendly interface and automated functions that simplify operation and maximize productivity. This user-centric approach reflects [Company Name]'s dedication to providing practical solutions that meet the needs of modern businesses and industries.Speaking about the launch of the [Model Name] Shredder Machine, [Spokesperson Name], the CEO of [Company Name], expressed his enthusiasm for the potential impact of this innovative technology. "We are thrilled to introduce the [Model Name] Shredder Machine to the market, as we believe it has the power to revolutionize the way waste is managed and processed across various industries. This state-of-the-art shredder embodies our commitment to technological excellence and sustainability, and we are confident that it will set a new standard in waste management."The introduction of the [Model Name] Shredder Machine comes at a time when businesses and industries are increasingly prioritizing sustainable and efficient waste management solutions. With its innovative features and potential for widespread applicability, this shredder has already generated considerable interest among prospective customers, signaling a promising future for [Company Name] in the waste management industry.As the demand for effective waste management solutions continues to grow, [Company Name] is poised to establish itself as a leading provider of cutting-edge machinery and equipment, with the [Model Name] Shredder Machine representing just one of many innovative products in its portfolio. With a strong emphasis on research and development, customer satisfaction, and environmental responsibility, [Company Name] is well-positioned to lead the way in shaping the future of waste management technology.In conclusion, the unveiling of the [Model Name] Shredder Machine marks a significant milestone for [Company Name] and the waste management industry as a whole. With its advanced features, versatile applications, and user-centric design, this cutting-edge shredder has the potential to revolutionize the way businesses and industries handle their waste, paving the way for a more sustainable and efficient future.

Efficient Plastic Pelletizer for High-Quality Production

Plastic manufacturing companies around the world are constantly looking for innovative solutions to improve their production processes and reduce waste. One company that has been at the forefront of developing cutting-edge solutions for the plastics industry is {}.{} is a leading manufacturer of plastic processing machinery and equipment, specializing in the design and production of plastic pelletizers. The company has a strong reputation for its high-quality products and innovative technologies, and it has been dedicated to helping plastic manufacturers streamline their production processes and minimize waste generation.One of {}'s most recent innovations is the development of a state-of-the-art plastic pelletizer that is revolutionizing the way plastic manufacturers process and recycle their materials. The new pelletizer is designed to efficiently and effectively convert plastic waste into high-quality pellets that can be used in a wide range of applications, including the manufacturing of new plastic products.The plastic pelletizer is equipped with advanced features and technologies that set it apart from traditional pelletizing equipment. It is designed to handle a wide variety of plastic materials, including both virgin and recycled plastics, and it can produce pellets of consistent size and quality. This level of precision and consistency is crucial for manufacturers who rely on high-quality pellets to produce their products.In addition to its advanced capabilities, the plastic pelletizer also offers enhanced energy efficiency and production capacity. Thanks to its innovative design and engineering, the pelletizer is able to process larger quantities of plastic materials in a shorter amount of time, reducing the overall energy consumption and labor costs associated with pelletizing operations.Furthermore, the plastic pelletizer is designed with a focus on sustainability and environmental responsibility. By enabling manufacturers to efficiently recycle their plastic waste and transform it into reusable pellets, the pelletizer plays a key role in reducing the environmental impact of plastic production and consumption. This aligns with {}'s commitment to developing eco-friendly solutions for the plastics industry.Another key advantage of the plastic pelletizer is its versatility. It can be customized to meet the specific needs and requirements of different plastic manufacturers, allowing them to optimize the pelletizing process for their unique production workflows. This level of flexibility is invaluable for companies that produce a wide range of plastic products and need a pelletizer that can adapt to their changing needs.The plastic pelletizer is already generating significant interest and excitement within the plastics industry, with many manufacturers recognizing the potential benefits it offers for their operations. By investing in this innovative technology, companies can improve their production processes, reduce waste, and contribute to a more sustainable and circular economy.As {} continues to lead the way in developing advanced solutions for the plastics industry, the company remains dedicated to supporting manufacturers in their efforts to improve efficiency, reduce environmental impact, and achieve their production goals. With its new plastic pelletizer, {} is poised to make a significant impact on the way plastic materials are processed and recycled, paving the way for a more sustainable and resource-efficient future for the plastics industry.

Benefits of Two Shaft Shredders for Industrial Waste Management

Two Shaft Shredders: The Latest Innovation in Waste ManagementIn today's fast-paced world, businesses are constantly seeking innovative solutions to improve efficiency and reduce waste. As environmental concerns continue to gain prominence, companies are under increasing pressure to find sustainable ways to manage their waste and minimize their impact on the environment. This has led to a growing demand for advanced shredding equipment that can effectively and efficiently process a wide range of materials, from paper and plastic to metal and electronics. Recognizing this need for cutting-edge waste management technology, {company name} has introduced a new range of Two Shaft Shredders that are poised to revolutionize the industry. Equipped with state-of-the-art features and built to the highest standards, these shredders are designed to deliver optimal performance and versatility, making them the ideal solution for businesses looking to streamline their waste management processes.The Two Shaft Shredders offered by {company name} are designed to handle a wide variety of materials, including paper, cardboard, plastic, wood, rubber, metal, and electronic waste. This versatility makes them an essential tool for businesses operating in diverse industries, from manufacturing and retail to logistics and waste management. Whether it’s reducing the volume of waste for easier disposal or destroying sensitive documents to protect sensitive data, these shredders offer unparalleled capabilities to effectively process a wide range of materials.One of the key features that sets the Two Shaft Shredders apart is their precision engineering, which ensures consistent performance and durability. The robust construction of these machines, combined with advanced cutting technology, allows them to effectively shred even the most difficult materials, such as hard plastics and metal components. This level of performance is crucial for businesses seeking to improve their waste management processes and reduce their environmental footprint.Moreover, {company name}'s Two Shaft Shredders are designed with user convenience in mind, featuring intuitive controls and safety mechanisms to ensure seamless operation and peace of mind. This user-friendly design makes the shredders suitable for businesses of all sizes, from small startups to large corporations, and allows operators to easily manage the shredding process with minimal training. This efficient and hassle-free operation is essential for businesses seeking to optimize their waste management processes without compromising on safety and productivity.In addition to their outstanding performance and user-friendly design, {company name}'s Two Shaft Shredders are also equipped with advanced safety features to protect operators and prevent accidents. These features include emergency stop buttons, safety interlocks, and overload protection, ensuring that the shredders can be operated with confidence and peace of mind. This focus on safety reflects {company name}'s commitment to providing reliable and responsible waste management solutions that prioritize the well-being of both operators and the environment.Furthermore, the Two Shaft Shredders offered by {company name} are designed to meet the highest standards of environmental sustainability, with energy-efficient motors and an optimized shredding process that minimizes power consumption. This eco-friendly approach aligns with the global trend towards sustainable waste management practices and positions {company name} as a responsible and forward-thinking provider of waste processing solutions. By investing in these shredders, businesses can not only improve their operational efficiency but also contribute to a more sustainable and environmentally responsible future.In conclusion, {company name}'s introduction of the Two Shaft Shredders represents a significant leap forward in the field of waste management technology. With their exceptional performance, user-friendly design, advanced safety features, and environmental sustainability, these shredders are set to become an essential tool for businesses seeking to improve their waste management processes and reduce their environmental impact. By investing in {company name}'s Two Shaft Shredders, businesses can take a proactive step towards optimizing their waste management operations and contributing to a more sustainable future.

High-Quality PVC Door Manufacturing Machine for Efficient Production

PVC Door Manufacturing Machine Revolutionizes the IndustryThe demand for PVC doors has been steadily increasing as more and more homeowners and businesses are looking for durable and cost-effective solutions for their building projects. To meet this growing demand, {Company Name} has introduced a state-of-the-art PVC Door Manufacturing Machine that is set to revolutionize the industry.This innovative machine is designed to streamline the production process and significantly reduce the time and labor required to manufacture high-quality PVC doors. With its advanced technology and precision engineering, the machine is capable of producing a wide range of PVC doors with different designs, sizes, and finishes, catering to the diverse needs of customers.The PVC Door Manufacturing Machine is equipped with the latest automation and control systems, ensuring high efficiency and accuracy in every step of the production process. From the mixing and preparation of PVC materials to the molding and finishing of the doors, the machine is able to consistently deliver superior quality products with minimal human intervention.One of the key features of the machine is its ability to produce PVC doors with excellent structural integrity and thermal insulation properties. This is particularly important for customers who are looking for energy-efficient and sustainable building solutions. With the use of high-quality PVC materials and the precise manufacturing process facilitated by the machine, the doors are able to meet the highest standards of performance and durability.In addition, the machine is also designed to be versatile and adaptable to changing market trends and customer preferences. It can easily accommodate customization options such as embossing, engraving, and color variations, allowing customers to create unique and personalized PVC doors for their projects.{Company Name} takes pride in its commitment to sustainability and environmental responsibility. The PVC Door Manufacturing Machine is designed to minimize material wastage and energy consumption, ensuring that the production process is as eco-friendly as possible. By investing in this advanced technology, the company aims to contribute to a greener and more sustainable future for the building materials industry.Furthermore, the introduction of this cutting-edge machine is expected to have a positive impact on the company’s production capacity and overall business operations. With increased efficiency and productivity, {Company Name} will be able to fulfill larger orders and meet tight deadlines, strengthening its position as a leading supplier of PVC doors in the market.As a customer-focused company, {Company Name} is dedicated to providing excellent service and support to its clients. The PVC Door Manufacturing Machine is backed by a team of skilled technicians and engineers who are well-trained in its operation and maintenance. This ensures that customers can rely on the machine to deliver consistent performance and reliability for years to come.In conclusion, the introduction of the PVC Door Manufacturing Machine by {Company Name} marks a significant milestone in the evolution of the PVC door industry. With its advanced technology, precision engineering, and commitment to sustainability, the machine is set to transform the way PVC doors are manufactured, offering customers high-quality products and exceptional value for their building projects. This innovative machine is a testament to {Company Name}'s dedication to innovation, quality, and customer satisfaction.