High-quality Pipe Grinding Machine for Industrial Use

By:Admin

At the forefront of industrial innovation, the latest Pipe Grinding Machine has emerged as a game-changer in the field of pipe processing. With its advanced technology and superior performance, this machine is set to revolutionize the way pipes are handled in various industries.

The Pipe Grinding Machine, developed by a leading engineering company, is designed to meet the growing demand for efficient and precise pipe processing. With its cutting-edge features and state-of-the-art technology, this machine is capable of grinding and polishing pipes with unparalleled accuracy and speed. This not only saves time and labor but also ensures a high-quality finish for the pipes, meeting the strict standards of various industries.

The company behind this groundbreaking machine has a long history of engineering excellence and innovation. With a team of experienced engineers and designers, they have consistently pushed the boundaries of what is possible in the field of industrial machinery. Their dedication to delivering cutting-edge solutions has earned them a reputation as a leader in the industry, and the Pipe Grinding Machine is a testament to their commitment to innovation.

One of the key features of the Pipe Grinding Machine is its ability to handle a wide range of pipe sizes and materials. Whether it's stainless steel, carbon steel, or any other material, this machine can effectively grind and polish pipes of various diameters and lengths. This versatility makes it an invaluable tool for industries such as construction, manufacturing, and oil and gas, where pipes of different specifications are used extensively.

Furthermore, the machine is equipped with advanced control systems and automation, allowing for precise and consistent results every time. This not only improves the efficiency of the pipe processing but also reduces the margin for error, ensuring that the end product meets the highest quality standards.

In addition to its superior performance, the Pipe Grinding Machine is also designed with the operator in mind. The user-friendly interface and intuitive controls make it easy for operators to set up and operate the machine, minimizing the need for extensive training and supervision. This means that companies can maximize their productivity and efficiency without having to allocate significant resources for training and supervision.

The Pipe Grinding Machine is also designed with sustainability in mind. Its energy-efficient operation and minimal waste generation make it an eco-friendly choice for companies looking to reduce their environmental footprint. By investing in this machine, companies can not only improve their operational efficiency but also contribute to a greener and more sustainable future.

With its revolutionary technology and impressive capabilities, the Pipe Grinding Machine is poised to bring about a paradigm shift in the way pipes are processed in industrial settings. Its ability to deliver precision, efficiency, and sustainability makes it a valuable asset for companies looking to stay ahead in a competitive market.

As industries continue to evolve and demand for high-quality, efficient pipe processing solutions grows, the Pipe Grinding Machine stands out as a cutting-edge solution that is set to redefine the standards of industrial pipe processing. With its unmatched performance and innovative design, it is a testament to the company's unwavering commitment to engineering excellence and innovation.

Company News & Blog

Powerful Shredder Plastic: Breaking Down Plastic Waste for Recycling

Plastic pollution is a growing concern around the globe, with millions of tons of plastic waste entering the environment every year. In an effort to combat this issue, companies are continually seeking innovative solutions to reduce, reuse, and recycle plastic materials. One such company at the forefront of this movement is {Company Name}, which has recently introduced a groundbreaking new product, the Shredder Plastic.{Company Name} is a leading manufacturer of sustainable packaging and plastic solutions, with a focus on environmental responsibility and innovation. The company prides itself on its commitment to reducing plastic waste and finding new ways to repurpose and recycle plastic materials. With a team of dedicated engineers and researchers, {Company Name} has developed the Shredder Plastic as a cutting-edge solution to tackle the plastic waste problem.The Shredder Plastic is a state-of-the-art machine that is capable of shredding and recycling various types of plastic waste. It is designed to process plastic materials such as bottles, containers, and packaging, breaking them down into smaller, more manageable pieces. This innovative technology allows for the efficient recycling of plastic waste, reducing the environmental impact and promoting a more sustainable approach to plastic management.The Shredder Plastic is equipped with advanced shredding mechanisms that can handle a wide range of plastic materials, including both rigid and flexible plastics. The machine is designed to operate with high efficiency, shredding plastic waste into uniform particles that can be easily processed and reused in the production of new plastic products. This closed-loop system promotes circular economy principles, ensuring that plastic materials are continuously recycled and repurposed, rather than ending up in landfills or polluting the environment.{Company Name} has also incorporated smart technology into the Shredder Plastic, allowing for real-time monitoring and control of the recycling process. This advanced system enables the machine to optimize its operations, reducing energy consumption and maximizing the recycling efficiency. As a result, the Shredder Plastic offers a sustainable and cost-effective solution for businesses looking to manage their plastic waste in an environmentally responsible manner.In addition to its environmental benefits, the Shredder Plastic also offers economic advantages for businesses and organizations. By implementing this innovative recycling technology, companies can reduce their waste disposal costs and potentially generate revenue from the recycled plastic materials. This creates a win-win scenario, where businesses can improve their sustainability efforts while also realizing financial savings.Furthermore, the Shredder Plastic aligns with {Company Name}'s overall mission to promote sustainability and environmental stewardship. The company is dedicated to providing solutions that not only meet the needs of its customers but also contribute to a greener and cleaner planet. Through the introduction of the Shredder Plastic, {Company Name} is taking a proactive stance in addressing the plastic waste crisis and championing a more sustainable approach to plastic recycling.As the global demand for sustainable packaging and plastic solutions continues to grow, the Shredder Plastic is poised to make a significant impact in the industry. With its cutting-edge technology, environmental benefits, and economic advantages, this innovative machine has the potential to revolutionize the way plastic waste is managed and recycled.In conclusion, {Company Name} has set a new standard in the fight against plastic pollution with the introduction of the Shredder Plastic. This groundbreaking technology exemplifies the company's commitment to sustainability and environmental responsibility, offering a game-changing solution for businesses seeking to reduce their plastic waste footprint. As the world seeks to address the plastic waste crisis, innovative products like the Shredder Plastic will undoubtedly play a critical role in creating a more sustainable and circular approach to plastic recycling.

Benefits of Two Shaft Shredders for Industrial Waste Management

Two Shaft Shredders: The Latest Innovation in Waste ManagementIn today's fast-paced world, businesses are constantly seeking innovative solutions to improve efficiency and reduce waste. As environmental concerns continue to gain prominence, companies are under increasing pressure to find sustainable ways to manage their waste and minimize their impact on the environment. This has led to a growing demand for advanced shredding equipment that can effectively and efficiently process a wide range of materials, from paper and plastic to metal and electronics. Recognizing this need for cutting-edge waste management technology, {company name} has introduced a new range of Two Shaft Shredders that are poised to revolutionize the industry. Equipped with state-of-the-art features and built to the highest standards, these shredders are designed to deliver optimal performance and versatility, making them the ideal solution for businesses looking to streamline their waste management processes.The Two Shaft Shredders offered by {company name} are designed to handle a wide variety of materials, including paper, cardboard, plastic, wood, rubber, metal, and electronic waste. This versatility makes them an essential tool for businesses operating in diverse industries, from manufacturing and retail to logistics and waste management. Whether it’s reducing the volume of waste for easier disposal or destroying sensitive documents to protect sensitive data, these shredders offer unparalleled capabilities to effectively process a wide range of materials.One of the key features that sets the Two Shaft Shredders apart is their precision engineering, which ensures consistent performance and durability. The robust construction of these machines, combined with advanced cutting technology, allows them to effectively shred even the most difficult materials, such as hard plastics and metal components. This level of performance is crucial for businesses seeking to improve their waste management processes and reduce their environmental footprint.Moreover, {company name}'s Two Shaft Shredders are designed with user convenience in mind, featuring intuitive controls and safety mechanisms to ensure seamless operation and peace of mind. This user-friendly design makes the shredders suitable for businesses of all sizes, from small startups to large corporations, and allows operators to easily manage the shredding process with minimal training. This efficient and hassle-free operation is essential for businesses seeking to optimize their waste management processes without compromising on safety and productivity.In addition to their outstanding performance and user-friendly design, {company name}'s Two Shaft Shredders are also equipped with advanced safety features to protect operators and prevent accidents. These features include emergency stop buttons, safety interlocks, and overload protection, ensuring that the shredders can be operated with confidence and peace of mind. This focus on safety reflects {company name}'s commitment to providing reliable and responsible waste management solutions that prioritize the well-being of both operators and the environment.Furthermore, the Two Shaft Shredders offered by {company name} are designed to meet the highest standards of environmental sustainability, with energy-efficient motors and an optimized shredding process that minimizes power consumption. This eco-friendly approach aligns with the global trend towards sustainable waste management practices and positions {company name} as a responsible and forward-thinking provider of waste processing solutions. By investing in these shredders, businesses can not only improve their operational efficiency but also contribute to a more sustainable and environmentally responsible future.In conclusion, {company name}'s introduction of the Two Shaft Shredders represents a significant leap forward in the field of waste management technology. With their exceptional performance, user-friendly design, advanced safety features, and environmental sustainability, these shredders are set to become an essential tool for businesses seeking to improve their waste management processes and reduce their environmental impact. By investing in {company name}'s Two Shaft Shredders, businesses can take a proactive step towards optimizing their waste management operations and contributing to a more sustainable future.

Highly Efficient Pulverizer Machine for Plastic - A Complete Guide

Pulverizer Machine For Plastic - A Game Changer in Plastic RecyclingIn the wake of increasing concern over plastic pollution, the need for effective plastic recycling solutions has never been more urgent. In response to this global challenge, {Company Name} has taken a significant step forward with the introduction of their advanced Pulverizer Machine for plastic recycling.The {Company Name} is a leading manufacturer and supplier of industrial machinery and equipment, specializing in the development of innovative solutions for the recycling industry. With a strong commitment to sustainability and environmental responsibility, the company has positioned itself as a driving force in the quest for efficient and effective plastic recycling technologies.The Pulverizer Machine for plastic is a cutting-edge innovation that is set to revolutionize the way plastic waste is processed and recycled. Unlike traditional recycling methods that rely on mechanical shredding and grinding, this advanced machine utilizes a sophisticated pulverizing technique to break down plastic materials into fine particles. This not only allows for a more thorough and efficient recycling process but also produces a higher quality end product.One of the key features of the Pulverizer Machine is its versatility and adaptability. The machine is designed to handle a wide range of plastic materials, including PET, HDPE, PVC, and more. This flexibility makes it an ideal solution for recycling facilities and businesses that deal with various types of plastic waste.In addition to its exceptional performance, the Pulverizer Machine is also designed with user-friendly features that enhance its ease of operation and maintenance. This includes a user-friendly interface, automated controls, and a durable, low-maintenance design. As a result, operators can maximize productivity and efficiency while minimizing downtime and maintenance costs.The introduction of the Pulverizer Machine for plastic is a testament to {Company Name}'s ongoing commitment to innovation and sustainability. By providing the recycling industry with a state-of-the-art solution, the company is not only addressing the pressing issue of plastic waste but also empowering businesses and organizations to make a tangible impact on the environment.The benefits of the Pulverizer Machine extend beyond its environmental impact. By streamlining the plastic recycling process and producing high-quality recycled materials, the machine also offers significant economic advantages. Businesses and recycling facilities that implement this innovative technology can expect to see improvements in their operational efficiency, cost savings, and overall profitability.Furthermore, the Pulverizer Machine aligns with the growing global emphasis on circular economy principles, which prioritize the reduction, reuse, and recycling of materials. In doing so, {Company Name} is not only contributing to a more sustainable future but also positioning itself as a leader in the transition towards a more circular and resource-efficient economy.As the demand for effective plastic recycling solutions continues to rise, {Company Name} is poised to play a pivotal role in shaping the industry's future. With the Pulverizer Machine for plastic, the company has demonstrated its commitment to driving innovation, promoting sustainability, and empowering its customers to make a positive impact on the environment.In conclusion, the introduction of the Pulverizer Machine for plastic represents a significant milestone for {Company Name} and the plastic recycling industry as a whole. By leveraging cutting-edge technology and a strong sustainability focus, the company has pioneered a game-changing solution that is set to redefine the way plastic waste is processed and recycled. As the momentum for sustainable and responsible plastic recycling continues to grow, the Pulverizer Machine stands ready to lead the charge towards a more sustainable and circular future.

Efficient HDPE Bottle Washing Line for Recycling Process

[Company Name] is proud to announce the launch of a new HDPE bottle washing line at its state-of-the-art recycling facility. This new line represents a significant investment in the company's commitment to sustainability and environmental stewardship.The HDPE bottle washing line is equipped with cutting-edge technology that allows for the efficient and effective cleaning of a wide range of HDPE bottles. This includes bottles used for packaging a variety of products, such as detergents, shampoos, and household cleaners. The line is designed to remove contaminants and impurities from the bottles, resulting in high-quality, clean HDPE material that can be used for the production of new plastic products."We are thrilled to introduce this new HDPE bottle washing line to our facility," said [Company Name]'s CEO. "At [Company Name], we are dedicated to finding innovative solutions for recycling and sustainability, and this new line will allow us to further advance our efforts in reducing the environmental impact of plastic waste."The launch of the HDPE bottle washing line aligns with [Company Name]'s broader mission to promote a circular economy by recycling and reusing plastic materials. By investing in advanced recycling technologies, [Company Name] aims to minimize the environmental impact of plastic waste and contribute to a more sustainable future.In addition to the environmental benefits, the new HDPE bottle washing line will also enhance [Company Name]'s ability to meet the growing demand for high-quality recycled plastic materials. This is particularly important as more and more companies are seeking sustainable alternatives to virgin plastic for their manufacturing needs.The installation of the HDPE bottle washing line is just one of many initiatives [Company Name] has undertaken to improve its recycling capabilities. The company has also implemented a comprehensive quality control process to ensure that the recycled HDPE material meets the highest standards for purity and consistency.Furthermore, [Company Name] is committed to working with its customers and partners to promote the use of recycled plastic materials. By offering a reliable supply of clean, high-quality HDPE material, the company aims to support the transition to a more sustainable and circular economy."We believe that recycling plays a crucial role in reducing the environmental impact of plastic waste," said [Company Name]'s CEO. "With the introduction of the new HDPE bottle washing line, we are excited to strengthen our position as a leader in the recycling industry and contribute to a more sustainable future."As [Company Name] continues to expand its recycling capabilities, the company remains focused on driving positive change in the industry. Through its investments in advanced technologies and commitment to sustainability, [Company Name] is well-positioned to make a meaningful impact in the ongoing effort to reduce plastic waste and promote a circular economy.The launch of the HDPE bottle washing line represents a significant milestone for [Company Name], and the company looks forward to the opportunities it will create for sustainable innovation and environmental progress. With its continued dedication to recycling and sustainability, [Company Name] is poised to lead the way towards a more circular and responsible approach to plastic usage.

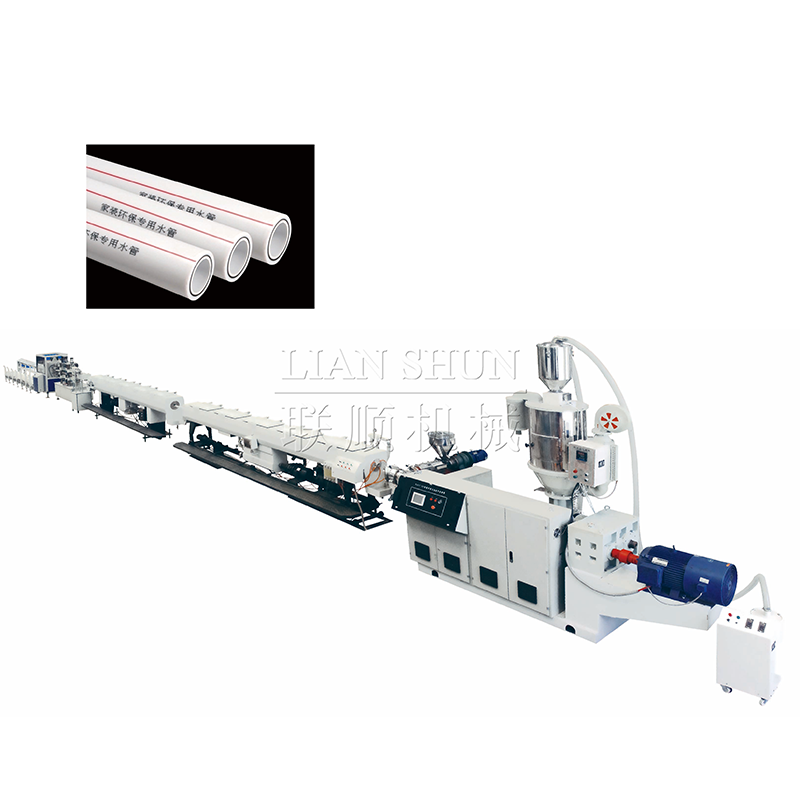

PVC Pipe Manufacturing Machine: An insight into the production process

PVC Pipe Manufacturing Machine Revolutionizes the IndustryThe global demand for PVC pipes is steadily increasing with the growth of construction activities, urbanization, and agricultural development. As a result, manufacturers are constantly seeking ways to increase their production capacity and efficiency. This quest for innovation has led to the development of the state-of-the-art PVC Pipe Manufacturing Machine, which is set to revolutionize the industry.The newly launched PVC Pipe Manufacturing Machine, developed by a prominent industry player (brand name removed), boasts cutting-edge technology and advanced features. This machine has been designed to streamline the entire production process, from raw material handling to the final product. It promises to significantly reduce the labor-intensive tasks associated with traditional manufacturing methods, resulting in increased productivity and cost-effectiveness for manufacturers.One of the key features of this PVC Pipe Manufacturing Machine is its automated operation. Equipped with modern control systems, it can perform complex tasks with minimal human intervention. This not only eliminates errors and inconsistencies but also enhances overall production efficiency. The machine ensures accurate and precise pipe dimensions, allowing manufacturers to deliver high-quality products consistently.Efficiency is further enhanced by the machine's capability to handle a wide range of pipe sizes. With customizable settings, manufacturers can produce pipes of various diameters and lengths as per their specific requirements. This flexibility enables them to cater to a broader market, providing a competitive edge in the industry.The advanced technology integrated into the PVC Pipe Manufacturing Machine also ensures energy optimization. With energy costs being a significant concern for manufacturers, this machine comes as a breath of fresh air. It minimizes power consumption by utilizing energy-efficient motors and advanced heating and cooling systems. This not only reduces operating costs but also contributes to sustainability efforts by lowering the carbon footprint of manufacturing processes.Moreover, the machine's user-friendly interface offers ease of operation and monitoring for operators. The control panel displays real-time data on production speed, error detection, and maintenance requirements, allowing operators to make informed decisions promptly. The automated quality control system constantly monitors the production process, identifying and rectifying any faults in real-time. This results in improved product consistency and reduced waste.Additionally, the PVC Pipe Manufacturing Machine's durability and reliability ensure long-term productivity. Constructed with high-quality materials and components, it can withstand the demands of continuous operation. This significantly reduces machine downtime and maintenance costs, translating into enhanced profitability for manufacturers.As a market leader in the manufacturing industry, the company behind this revolutionary machine is committed to providing exceptional customer support. They offer comprehensive training for machine operators to ensure efficient utilization and maximize its potential. Additionally, their after-sales service includes prompt technical assistance, spare parts availability, and regular maintenance. This commitment to customer satisfaction sets them apart from their competitors.Overall, the introduction of the PVC Pipe Manufacturing Machine marks a significant breakthrough in the industry. Its advanced features, energy efficiency, flexibility, and reliability are set to redefine the manufacturing process for PVC pipes. With its ability to meet the growing demands of the market, this innovative machine will undoubtedly revolutionize the global PVC pipe industry and drive greater growth and success for manufacturers worldwide.

Affordable Recycling Machines for Sale: Find the Best Prices Today

[Company Introduction]{Company Name} is a leading provider of waste management and recycling solutions. With a focus on sustainability and environmental responsibility, {Company Name} offers a range of products and services aimed at reducing the impact of waste on the planet. The company's mission is to create a more sustainable future by providing innovative and effective recycling solutions for businesses and communities.[Recycling Machines Price]In line with their commitment to environmental sustainability, {Company Name} has recently announced the launch of their latest recycling machine, designed to make recycling more convenient and efficient for consumers. The new machine, equipped with state-of-the-art technology, simplifies the recycling process, making it easier for individuals to contribute to a more sustainable future.At an introductory price of $5000, the recycling machine is a cost-effective investment for businesses and organizations looking to incorporate sustainable practices into their operations. With its compact design and user-friendly interface, the machine is suitable for a wide range of settings, including offices, schools, public spaces, and more. The affordable price point makes it an accessible option for businesses of all sizes, furthering {Company Name}'s mission to make recycling a viable and realistic option for all.The new recycling machine comes equipped with advanced sorting capabilities, allowing it to effectively separate various types of recyclable materials. This feature not only streamlines the recycling process but also ensures that materials are properly sorted and prepared for further processing, contributing to the overall efficiency of the recycling chain. Additionally, the machine includes a user-friendly interface, making it easy for individuals to operate and engage with the recycling process.{Company Name} has emphasized that the affordability of the new recycling machine does not compromise its quality or performance. Built to the highest standards, the machine is durable and reliable, capable of withstanding regular use in high-traffic environments. Furthermore, {Company Name} offers comprehensive support and maintenance services, ensuring that the machine continues to operate at peak performance over time.The unveiling of the new recycling machine is a significant step forward for {Company Name} in their efforts to promote sustainable waste management practices. By making recycling more accessible and convenient, the company aims to encourage greater participation in recycling initiatives, ultimately reducing the amount of waste that ends up in landfills and incinerators. This, in turn, contributes to the conservation of natural resources and the mitigation of environmental pollution.The launch of the new recycling machine is a testament to {Company Name}'s dedication to innovation and sustainability. By offering a high-quality, affordable solution for recycling, the company is empowering businesses and communities to take proactive steps towards a greener, more sustainable future. As awareness of the environmental impact of waste continues to grow, the demand for accessible and effective recycling solutions is on the rise, and {Company Name} is poised to meet this demand with their latest offering.{Company Name} remains committed to advancing the cause of environmental sustainability through their range of products and services. The new recycling machine, with its competitive price and cutting-edge features, is a testament to the company's ongoing efforts to make a positive impact on the planet. As businesses and individuals increasingly prioritize sustainability, {Company Name} is well-positioned to lead the way in providing practical, effective solutions for waste management and recycling.

High-Quality Upvc Profile Extrusion Machine for Efficient Production

The Upvc Profile Extrusion Machine is a cutting-edge piece of technology that is revolutionizing the production of UPVC profiles in the industry. This state-of-the-art machine is designed to produce high-quality UPVC profiles with precision and efficiency, meeting the increasing demand for UPVC profiles in the construction and manufacturing sectors.The Upvc Profile Extrusion Machine is manufactured by a leading company that has been a pioneer in the field of plastic extrusion machinery for many years. With a strong focus on research and development, the company has consistently produced innovative and reliable machinery solutions for its customers around the world. The company’s commitment to quality and customer satisfaction has earned it a sterling reputation in the industry.The Upvc Profile Extrusion Machine is equipped with advanced technology and features that make it stand out from other extrusion machines on the market. It is capable of producing a wide range of UPVC profiles, including window and door frames, pipes, and other custom profiles. The machine’s high precision and efficiency ensure that the produced profiles meet the strictest quality standards, making it an ideal choice for manufacturers who require top-quality UPVC profiles for their projects.One of the key features of the Upvc Profile Extrusion Machine is its versatility. With its modular design and customizable options, the machine can be tailored to meet the specific production needs of different manufacturers. This flexibility allows manufacturers to produce a variety of UPVC profiles with different shapes, sizes, and specifications, making the machine a valuable asset for companies with diverse production requirements.The Upvc Profile Extrusion Machine is also designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it simple for operators to set up and operate the machine, minimizing the need for extensive training and reducing the risk of errors during production. This user-friendly design enhances productivity and efficiency, allowing manufacturers to maximize their output and meet tight production deadlines.In addition to its cutting-edge technology and user-friendly design, the Upvc Profile Extrusion Machine also prioritizes energy efficiency and sustainability. The machine is engineered to minimize energy consumption and reduce waste, helping manufacturers lower their operating costs and minimize their environmental impact. This focus on sustainability aligns with the growing demand for eco-friendly manufacturing practices and positions the machine as a responsible choice for forward-thinking manufacturers.Overall, the Upvc Profile Extrusion Machine is a game-changer for the industry, offering manufacturers a powerful and reliable solution for producing high-quality UPVC profiles. With its advanced technology, versatility, user-friendly design, and sustainability features, the machine is poised to set new standards for UPVC profile production and empower manufacturers to meet the evolving demands of the market.In conclusion, the Upvc Profile Extrusion Machine is a testament to the company’s commitment to innovation, quality, and customer satisfaction. With its innovative technology and user-centered design, the machine promises to revolutionize UPVC profile production and empower manufacturers to succeed in a competitive and rapidly evolving industry. As the demand for UPVC profiles continues to grow, the Upvc Profile Extrusion Machine stands out as a reliable and cutting-edge solution for manufacturers looking to meet the highest standards of quality and efficiency in their production processes.

Efficient Pipe Crusher for Effective Waste Management

Pipe Crusher, a leading innovator in the field of industrial waste management, has recently introduced a revolutionary new product that promises to revolutionize the way companies handle their waste disposal. The Pipe Crusher, also known as the PC 1000, is a powerful machine designed to shred large pipes and tubes into smaller pieces, making them easier to handle and transport for recycling or proper disposal.With a strong commitment to sustainability and environmental responsibility, Pipe Crusher has been at the forefront of developing cutting-edge solutions for the growing problem of industrial waste. The company's mission is to provide efficient, cost-effective, and eco-friendly waste management solutions that help businesses minimize their environmental impact while maximizing their operational efficiency.The PC 1000 is the latest addition to Pipe Crusher's lineup of innovative waste management equipment. This powerful machine is capable of shredding large pipes and tubes with diameters of up to 1000mm, reducing them to small, manageable pieces in a matter of minutes. This not only makes it easier to transport the waste for recycling or disposal but also helps businesses save time and money on waste management.One of the key features of the PC 1000 is its high-performance motor, which enables the machine to process large volumes of waste quickly and efficiently. The shredding mechanism is designed to handle tough, industrial-grade materials, ensuring that the PC 1000 can effectively reduce even the most challenging waste products to manageable sizes.In addition to its impressive performance, the PC 1000 is also designed with safety and ease of use in mind. The machine is equipped with advanced safety features to protect operators and other personnel from potential hazards during operation. Additionally, it is designed for simple, user-friendly operation, making it easy for businesses to integrate the PC 1000 into their existing waste management processes.The introduction of the PC 1000 reflects Pipe Crusher's ongoing commitment to providing innovative solutions for industrial waste management. In a world where sustainability and environmental responsibility are increasingly important, the company's products and services are driving positive change by helping businesses minimize their environmental impact and maximize resource efficiency.Pipe Crusher has built a strong reputation for reliability, quality, and innovation in the field of waste management. With a team of experienced engineers and industry experts, the company is dedicated to developing cutting-edge solutions that help businesses meet their waste management needs effectively and responsibly.The PC 1000 is the latest example of Pipe Crusher's ongoing efforts to push the boundaries of waste management technology, and it is poised to make a significant impact on the industry. As businesses across various sectors continue to prioritize sustainability and environmental responsibility, innovative solutions like the PC 1000 are likely to become increasingly important in the years to come.In conclusion, Pipe Crusher's introduction of the PC 1000 represents a significant milestone in the field of industrial waste management. With its powerful performance, advanced safety features, and user-friendly design, the PC 1000 promises to revolutionize the way companies handle their waste disposal, setting a new standard for efficiency, sustainability, and environmental responsibility in the industry. As the demand for innovative waste management solutions continues to grow, Pipe Crusher is well-positioned to lead the way with its cutting-edge products and unwavering commitment to environmental stewardship.

High-quality Plastic Screw Extruder for Efficient Production

Plastic Screw Extruder: Revolutionizing the Plastic Manufacturing IndustryThe plastic manufacturing industry has seen a significant revolution in recent years, thanks to the innovation and technological advancements in plastic screw extruders. (Remove brand name) has been at the forefront of this revolution, offering state-of-the-art plastic screw extruders that have redefined the way plastic products are manufactured. With a commitment to quality, innovation, and customer satisfaction, (remove brand name) has made a significant impact on the plastic manufacturing industry.Plastic screw extruders are machines that are used to process plastic materials and shape them into various forms. They are commonly used in the production of a wide range of plastic products, including pipes, tubes, films, and sheets. The process involves feeding plastic material into the extruder, where it is melted and then forced through a die to create the desired shape. This technology has revolutionized the plastic manufacturing industry, making it possible to produce high-quality plastic products at a faster rate and with greater precision.(remove brand name) has been a key player in the development and manufacturing of plastic screw extruders. With a strong focus on research and development, the company has consistently delivered cutting-edge extrusion technology that has set new standards in the industry. The company's plastic screw extruders are known for their high precision, reliability, and energy efficiency, making them the preferred choice for many plastic manufacturers around the world.One of the key innovations introduced by (remove brand name) is the use of advanced materials and coatings in their extruders, which has significantly improved performance and durability. This has allowed plastic manufacturers to achieve higher productivity and efficiency, while also reducing maintenance and downtime. In addition, (remove brand name) has incorporated advanced control systems in their extruders, allowing for greater precision and flexibility in the manufacturing process.The company's commitment to customer satisfaction has also been a driving force behind the success of their plastic screw extruders. With a team of experienced engineers and technical support staff, (remove brand name) provides comprehensive support to their customers, helping them optimize the performance of their extruders and maximize their operational efficiency. This has helped (remove brand name) build strong relationships with their customers and establish a reputation for excellence in the industry.In addition to their innovative technology and exceptional customer support, (remove brand name) has also been proactive in addressing the environmental impact of plastic manufacturing. The company has developed extruders that are designed to minimize waste and energy consumption, helping manufacturers reduce their carbon footprint and operate in a more sustainable manner. By promoting the use of recycled materials and improving the efficiency of the extrusion process, (remove brand name) is contributing to the global effort to reduce plastic waste and protect the environment.Looking ahead, (remove brand name) is committed to advancing the field of plastic extrusion technology even further. The company continues to invest in research and development, with a focus on developing new materials, technologies, and processes that will further enhance the performance and sustainability of their extruders. This dedication to innovation and progress ensures that (remove brand name) will remain at the forefront of the plastic manufacturing industry, driving the evolution of plastic screw extrusion technology for years to come.In conclusion, (remove brand name) has made a significant impact on the plastic manufacturing industry with its advanced plastic screw extruders. Through their commitment to quality, innovation, and customer satisfaction, the company has set new standards in the industry and continues to drive the evolution of plastic extrusion technology. With a focus on performance, reliability, and sustainability, (remove brand name) is well-positioned to lead the industry into the future, shaping the way plastic products are manufactured and contributing to a more sustainable world.

High-quality PVC Conduit Pipe Machine for Efficient Pipe Manufacturing

The demand for PVC conduit pipe machines has been on the rise as the construction industry continues to grow. These machines are essential for the production of PVC conduit pipes, which are widely used to protect and route electrical wiring in buildings. Recognizing the increasing need for high-quality, efficient PVC conduit pipe machines, {Company Name} has developed a state-of-the-art machine that is set to revolutionize the industry.{Company Name} is a leading manufacturer of plastic extrusion machinery, with a strong focus on innovation and technological advancement. With years of experience in the industry, the company has built a reputation for producing top-of-the-line equipment that meets the highest standards of quality and performance.The {Company Name} PVC conduit pipe machine is the latest addition to their product lineup, and it comes with a range of advanced features designed to streamline the production process and improve overall efficiency. The machine is capable of producing PVC conduit pipes of various sizes and specifications, making it suitable for a wide range of applications in the construction industry.One of the key highlights of the {Company Name} PVC conduit pipe machine is its precision and accuracy. The machine is engineered to deliver consistent and reliable performance, ensuring that every PVC conduit pipe produced meets the required specifications and quality standards. This level of precision is essential for ensuring the safety and reliability of electrical installations in buildings, making the {Company Name} machine a valuable asset for manufacturers and contractors alike.In addition to its precision, the {Company Name} PVC conduit pipe machine also offers enhanced speed and efficiency. The machine is equipped with advanced automation and control systems that optimize the production process, allowing for faster turnaround times and increased productivity. This is particularly important in today's fast-paced construction industry, where timely completion of projects is essential.Furthermore, the {Company Name} PVC conduit pipe machine is designed with durability and longevity in mind. The machine is built to withstand the rigors of continuous operation, ensuring minimal downtime and maintenance requirements. This level of reliability is a key factor for manufacturers looking to maximize their production output and minimize production costs.The {Company Name} PVC conduit pipe machine also prioritizes user-friendliness and ease of operation. The machine is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up and run the production process with minimal training. This ensures that manufacturers can quickly integrate the machine into their production line and start reaping the benefits of its advanced capabilities.The introduction of the {Company Name} PVC conduit pipe machine has already generated significant interest in the industry. Manufacturers and contractors are eager to take advantage of the machine's advanced features and capabilities, recognizing the potential for improved efficiency and quality in their PVC conduit pipe production processes.In conclusion, {Company Name} has once again demonstrated its commitment to innovation and excellence with the introduction of the PVC conduit pipe machine. With its advanced features, precision, efficiency, and durability, the machine is set to make a significant impact on the production of PVC conduit pipes in the construction industry. As demand for high-quality PVC conduit pipes continues to grow, the {Company Name} PVC conduit pipe machine is poised to become an indispensable asset for manufacturers looking to stay ahead of the competition.