High-Quality Pp Pipe Machine: Latest Updates and Industry Insights

By:Admin

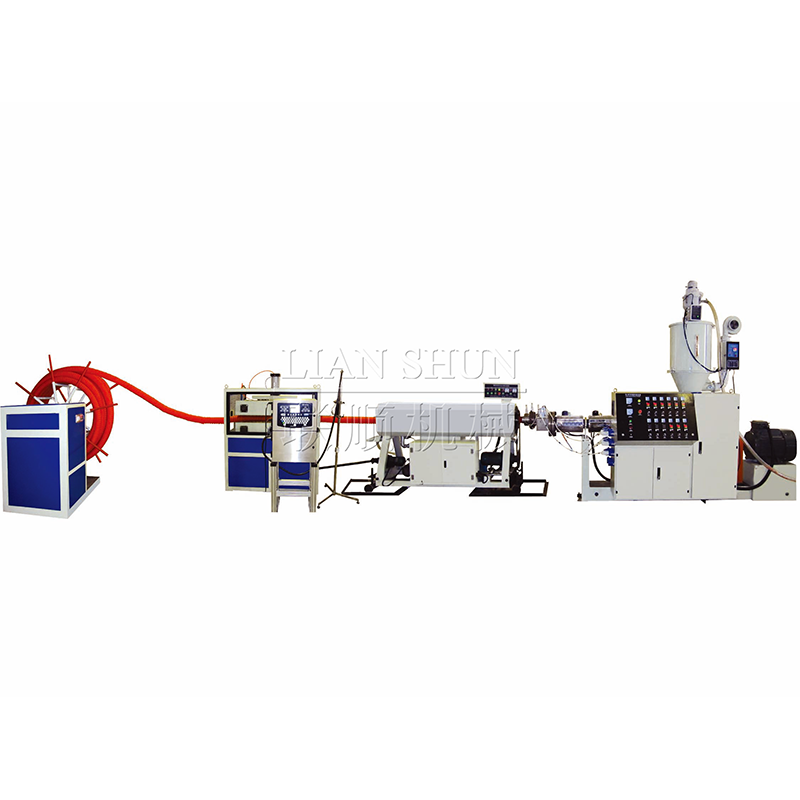

The PP Pipe Machine is the result of {Company Name}'s extensive research and development efforts, aimed at providing its customers with advanced and efficient solutions for pipe production. With a focus on precision engineering and technological innovation, the machine offers a range of features that set it apart in the market.

One of the key advantages of the PP Pipe Machine is its ability to produce pipes with superior strength and durability. The machine is equipped with advanced extrusion technology that ensures the uniform distribution of material, resulting in pipes that are resistant to corrosion, heat, and chemical damage. This makes the pipes suitable for a wide range of applications, including water supply, drainage, irrigation, and industrial fluid transport.

In addition to its exceptional product quality, the PP Pipe Machine also boasts high production efficiency. With a fully automated operation and precision control systems, the machine is able to maintain a high production speed while ensuring consistent pipe dimensions and wall thickness. This not only increases the output capacity but also reduces production costs for manufacturers, making it a highly cost-effective solution for pipe production.

Furthermore, the PP Pipe Machine is designed for versatility, allowing for the production of pipes in various sizes and specifications. This flexibility enables manufacturers to cater to a diverse range of customer requirements, while also adapting to evolving market demands. Additionally, the machine is equipped with user-friendly interfaces and controls, making it easy for operators to set up, monitor, and adjust the production parameters as needed.

With its cutting-edge technology and superior performance, the PP Pipe Machine is poised to make a significant impact in the plastic pipe manufacturing industry. {Company Name} is confident that the machine will not only meet the current needs of its customers but also drive innovation and growth in the industry as a whole.

{Company Name} is a globally recognized leader in the design and manufacture of plastic machinery, with a strong focus on delivering high-quality, reliable, and efficient solutions to its customers. With a proven track record of innovation and excellence, the company has established itself as a trusted partner for manufacturers across various industries, offering a comprehensive range of plastic machinery including extrusion lines, injection molding machines, and auxiliary equipment.

In addition to its advanced technology and product quality, {Company Name} places a strong emphasis on customer satisfaction and support. The company is committed to providing comprehensive pre-sales and after-sales services, including technical consultation, equipment installation and commissioning, and ongoing maintenance and support. This approach has earned {Company Name} a reputation for reliability and trustworthiness, further solidifying its position as a leading supplier in the plastic machinery market.

Looking ahead, {Company Name} remains dedicated to driving innovation and excellence in the plastic machinery industry, and the launch of the PP Pipe Machine is a testament to the company's ongoing commitment to meeting the evolving needs of its customers and the industry as a whole. With its cutting-edge technology and superior performance, the PP Pipe Machine is set to elevate the standards of pipe production, offering manufacturers a reliable and efficient solution for meeting the growing demand for high-quality polypropylene pipes.

Company News & Blog

How to Choose the Best Plastic Machine for PVC Pipe Production

Pvc Pipe Plastic Machine Manufacturer Leads the Way in Innovation and SustainabilityIn recent years, the global plastic industry has been undergoing a transformation towards sustainability and innovation. One company at the forefront of this movement is (company name), a leading manufacturer of pvc pipe plastic machines. With a strong focus on research and development, the company has been actively developing new technologies and processes to meet the growing demand for sustainable and efficient plastic production.Established in (year), (company name) has quickly grown to become a key player in the plastic machinery industry. With a state-of-the-art production facility and a team of highly skilled engineers and technicians, the company has built a solid reputation for delivering high-quality and reliable pvc pipe plastic machines to customers worldwide.In line with the industry's shift towards sustainability, (company name) has been proactive in developing eco-friendly solutions for plastic production. The company's innovative pvc pipe plastic machines are designed to minimize energy consumption and reduce waste, making them a valuable asset for businesses looking to improve their environmental footprint.One of the key factors contributing to the company's success is its dedication to research and development. (company name) invests heavily in R&D, constantly seeking to improve its existing products and develop new technologies to address the evolving needs of the plastic industry. By staying ahead of the curve, the company has been able to offer cutting-edge solutions to its customers, helping them stay competitive in a rapidly changing market.The company's commitment to innovation is also evident in its efforts to incorporate advanced automation and digitalization into its pvc pipe plastic machines. By leveraging the latest technologies, (company name) is able to deliver more efficient and cost-effective solutions to its customers, further enhancing the competitiveness of their businesses.In addition to its technological advancements, (company name) places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provide tailored solutions to meet their production needs. With a dedicated team of professionals, (company name) offers comprehensive support and technical assistance to ensure that its customers are able to maximize the performance of their pvc pipe plastic machines.Looking ahead, (company name) remains committed to leading the way in innovation and sustainability within the plastic machinery industry. The company continues to invest in R&D and explore new opportunities to further improve the efficiency and environmental impact of its products. With a focus on customer-centric solutions and a dedication to excellence, (company name) is well-positioned to drive the industry forward in the years to come.In conclusion, (company name) is a shining example of a company that is not only embracing innovation and sustainability but also leading the way for others in the plastic machinery industry. With its cutting-edge pvc pipe plastic machines and a strong commitment to customer satisfaction, the company is well-equipped to meet the evolving needs of the market and contribute to a more sustainable and efficient future for the industry.

Industrial Recycling Shredder: A Complete Guide

Recycling Shredder: A Solution for Sustainable Waste ManagementIn today's world, the issue of waste management has become more critical than ever. With the global population increasing and the amount of waste produced growing at an alarming rate, it has become essential to find sustainable solutions for managing and recycling waste. One company that has been leading the way in this endeavor is {Company Name}, which has developed an innovative recycling shredder that is revolutionizing the recycling industry.{Company Name} is a leading provider of environmentally friendly waste management solutions, with a strong commitment to sustainability and environmental responsibility. The company's mission is to provide efficient and effective waste management solutions that minimize environmental impact and make a positive contribution to the planet. With a focus on developing cutting-edge technology and sustainable processes, {Company Name} has become a trusted name in the recycling industry.One of the company's most significant achievements is the development of a state-of-the-art recycling shredder that sets a new standard for efficiency and performance in waste management. This cutting-edge machine is designed to process a wide range of materials, including plastic, paper, cardboard, and electronic waste, making it a versatile and cost-effective solution for recycling facilities and waste management companies.The recycling shredder is equipped with advanced shredding technology that allows it to process large volumes of material quickly and efficiently. Its high-speed motor and precision cutting blades ensure that it can handle even the toughest and most challenging materials with ease, making it a valuable asset for any recycling operation. Furthermore, the shredder is designed to minimize energy consumption and reduce operating costs, making it a sustainable and environmentally friendly solution for waste management.{Company Name} has also invested in research and development to continuously improve the performance and capabilities of its recycling shredder. The company's team of engineers and experts are dedicated to enhancing the machine's efficiency, reliability, and durability, ensuring that it remains at the forefront of waste management technology. As a result, the recycling shredder has become a game-changer for recycling facilities, allowing them to increase their processing capacity, reduce waste volumes, and improve their overall operational efficiency.Moreover, the recycling shredder's user-friendly design and intuitive controls make it easy to operate and maintain, providing operators with a hassle-free and seamless experience. Its robust construction and high-quality components ensure that it can withstand the demanding conditions of waste processing facilities, minimizing downtime and maximizing productivity. Additionally, the shredder is designed to meet stringent safety standards, providing operators with peace of mind and a secure working environment.{Company Name} is dedicated to providing comprehensive support and service for its recycling shredder, ensuring that customers receive ongoing assistance and technical expertise. The company's team of professionals is committed to helping clients integrate the shredder into their operations, providing training, maintenance, and troubleshooting services as needed. With a focus on customer satisfaction and long-term partnerships, {Company Name} aims to deliver value and excellence in every aspect of its business.The recycling shredder from {Company Name} is a testament to the company's commitment to innovation, sustainability, and environmental stewardship. By providing a reliable and efficient solution for waste management, the company is playing a crucial role in building a more sustainable and circular economy. With its cutting-edge technology and dedication to excellence, {Company Name} is leading the way toward a greener and more sustainable future for waste management.In conclusion, the recycling shredder from {Company Name} is a game-changing solution for sustainable waste management, offering unmatched efficiency, performance, and reliability. As the demand for environmentally friendly waste solutions continues to grow, {Company Name} is well-positioned to make a significant and positive impact on the recycling industry. With its ongoing commitment to innovation and sustainability, the company is set to remain a leader in the field of waste management for years to come.

Efficient and Reliable PVC Pipe Making Machine Unveiled, Promising Sturdy Manufacturing Results

Title: Innovative Rigid PVC Pipe Making Machine Revolutionizes Manufacturing ProcessIntroduction:In today's ever-evolving industrial landscape, innovation plays a crucial role in boosting productivity and efficiency. Breaking barriers with its groundbreaking technology, the Rigid PVC Pipe Making Machine (brand name removed) is set to revolutionize the manufacturing process, making it faster, more reliable, and cost-effective. This cutting-edge machine, developed by a leading company in the field, incorporates advanced features designed to meet the demands of the PVC pipe industry. In this article, we will delve into the innovative aspects of this machine, highlighting its potential impact on the manufacturing sector.1. Precision and Efficiency:The Rigid PVC Pipe Making Machine represents a significant step forward in the quest for precision and efficiency in industrial processes. This state-of-the-art machine integrates advanced components and modern technologies, enabling it to provide accurate and consistent results. The precise control system allows for greater control over key parameters such as temperature, pressure, and speed, ensuring the production of high-quality pipes with minimal material wastage. Moreover, the machine's automated procedures reduce manpower requirements, thereby boosting overall efficiency and cost-effectiveness.2. Versatility and Adaptability:The Rigid PVC Pipe Making Machine offers remarkable versatility and adaptability, making it suitable for a wide range of pipe production requirements. The machine is designed to accommodate various pipe diameters and thicknesses, making it an ideal choice for both small-scale and large-scale PVC pipe manufacturers. The flexibility provided by this machine allows manufacturers to produce an array of pipes to cater to diverse industry needs, whether for irrigation, plumbing, or industrial applications. Its ability to accommodate different pipe specifications allows for increased customization, meeting the unique demands of customers.3. Energy Efficiency and Environmental Consciousness:Acknowledging the importance of sustainable practices in today's world, the Rigid PVC Pipe Making Machine integrates energy-efficient features that contribute to reduced energy consumption, thereby minimizing the carbon footprint of the manufacturing process. Advanced insulation technology ensures minimal energy loss, optimizing thermal efficiency. Additionally, the machine incorporates modern filtration systems that effectively remove impurities and minimize waste generation, promoting environmental consciousness and sustainability. This eco-friendly approach aligns with global efforts to adopt greener manufacturing practices.4. Streamlined Operation and Maintenance:Ease of operation and maintenance are crucial factors in modern machinery, and the Rigid PVC Pipe Making Machine excels in both areas. Its user-friendly interface and intuitive controls simplify machine operation, reducing the learning curve for operators. Additionally, the machine's self-diagnostic capabilities enable early detection of potential issues, minimizing downtime and ensuring uninterrupted production. Regular maintenance requirements are simplified with accessible components and a robust design, reducing maintenance costs and increasing overall equipment lifespan.Conclusion:The introduction of the Rigid PVC Pipe Making Machine highlights the continuous progress being made in the manufacturing sector. By combining precision, versatility, energy efficiency, and streamlined operation, this innovative machine sets a new standard for the production of PVC pipes. Its ability to meet the diverse demands of the industry while delivering high-quality results showcases its potential to revolutionize the manufacturing process. As industries strive for enhanced productivity and sustainability, the Rigid PVC Pipe Making Machine emerges as a game-changer in the industry, paving the way for a more efficient and eco-conscious manufacturing landscape.

Efficient Manufacturing Machine for Electrical PVC Pipe Production Unveiled

Title: Revolutionary Electrical PVC Pipe Manufacturing Machine Set to Transform the IndustryIntroduction:In a bid to revolutionize the Electrical PVC Pipe Manufacturing industry, a renowned manufacturing company has developed an innovative machine that promises to streamline the production process while maintaining the highest standards of quality and efficiency. By integrating cutting-edge technology, this groundbreaking device aims to enhance productivity levels, reduce resource consumption, and meet the increasing demands of the market. This article delves into the key features and potential benefits of this game-changing manufacturing machine.Section 1: Background and Industry Overview (150 words)The Electrical PVC Pipe Manufacturing industry has experienced steady growth in recent years due to the increasing demand for electrical infrastructure in both commercial and residential sectors. Traditionally, the manufacturing process involved multiple stages, leading to higher production costs and longer lead times. However, with technological advancements paving the way for innovation, companies are constantly seeking ways to optimize their manufacturing processes.Section 2: Introduction of the Electrical PVC Pipe Manufacturing Machine (150 words)The new Electrical PVC Pipe Manufacturing Machine brings a fresh perspective to the industry by leveraging state-of-the-art technology. This fully automated machine is designed to integrate various production processes, from raw material preparation to final product packaging, into a single streamlined operation. By eliminating the need for manual labor and multiple machines, this device promises to significantly enhance productivity levels, reduce production time, and offer superior quality control.Section 3: Features and Benefits of the Electrical PVC Pipe Manufacturing Machine (250 words)- Advanced Technology: The manufacturing machine utilizes cutting-edge technology, including computer numerical control (CNC) systems, to ensure precise and consistent pipe production. This technology enables measurements and adjustments to be made with unprecedented accuracy, resulting in high-quality end products.- Enhanced Efficiency: Through the integration of various processes into a single operation, the machine maximizes efficiency by minimizing the time required for material handling, equipment setup, and changeovers. This leads to higher production rates, shorter lead times, and reduced manufacturing costs.- Quality Assurance: The machine incorporates automatic quality control mechanisms, which continually monitor and adjust key parameters during the manufacturing process. With this feature, manufacturers can ensure that each PVC pipe produced meets the required specifications, leading to improved customer satisfaction.- Eco-Friendly Operation: The machine is designed with sustainability in mind. Its energy-efficient systems and optimized resource consumption minimize waste, reducing the overall environmental impact of the manufacturing process.- Versatile Production: The machine is adaptable to various pipe sizes and specifications, allowing manufacturers to cater to a wide range of customer requirements. This flexibility ensures a competitive edge in the market, enabling companies to respond quickly to evolving industry demands.Section 4: Conclusion (100 words)The introduction of the Electrical PVC Pipe Manufacturing Machine signifies a milestone in the evolution of the industry. By combining advanced technology, streamlined processes, and environmental sustainability, this game-changing device has the potential to revolutionize the manufacturing landscape. As companies seek ways to increase productivity, reduce costs, and meet customer demands, the utilization of this machine could serve as a catalyst for success in the highly competitive Electrical PVC Pipe Manufacturing industry.

Innovative Plastic Melter Densifier: A Sustainable Solution for Plastic Waste Management

[Company Name] Introduces Innovative Solution to Plastic Waste CrisisIn response to the global plastic waste crisis, [Company Name] has introduced an innovative solution that promises to revolutionize the way we handle plastic waste. The Plastic Melter Densifier, developed by [Company Name], is a groundbreaking technology that can effectively reduce the volume of plastic waste while also producing a valuable end product.The Plastic Melter Densifier is a compact machine that can process various types of plastic waste, including bottles, packaging materials, and other forms of plastic debris. Using a combination of heat and pressure, the machine is able to melt the plastic waste and compress it into dense, manageable blocks. This not only reduces the volume of the plastic waste but also creates a valuable end product that can be sold to manufacturers for use in the production of new plastic products.One of the key advantages of the Plastic Melter Densifier is its ability to handle mixed plastic waste. Unlike traditional recycling methods, which often require the sorting and separation of different types of plastic, the Plastic Melter Densifier can process mixed plastic waste without the need for sorting. This makes it a highly efficient and cost-effective solution for businesses and municipalities looking to manage their plastic waste in a sustainable manner.In addition to its environmental benefits, the Plastic Melter Densifier also offers a number of economic advantages. By reducing the volume of plastic waste and creating a valuable end product, businesses and municipalities can not only save on disposal costs but also generate new revenue streams by selling the compressed plastic blocks to manufacturers. This can help offset the initial investment in the machine and ultimately make the management of plastic waste a profitable endeavor.[Company Name] is committed to providing sustainable solutions to the growing problem of plastic waste. With the Plastic Melter Densifier, the company aims to help businesses and municipalities reduce their environmental impact while also creating new opportunities for economic growth. By offering a practical and efficient way to manage plastic waste, [Company Name] is paving the way for a more sustainable future.As concerns about the environmental impact of plastic waste continue to grow, the introduction of the Plastic Melter Densifier comes at a critical time. With its innovative technology and potential for both environmental and economic benefits, this solution has the potential to make a significant impact on the way we manage plastic waste. By working with businesses and municipalities to implement this new technology, [Company Name] is taking a proactive approach to addressing the plastic waste crisis and creating a more sustainable path forward.The Plastic Melter Densifier is currently available for businesses and municipalities looking for a sustainable solution to their plastic waste management needs. With its compact size, efficient operation, and potential for cost savings, this machine is poised to become a game-changer in the field of plastic waste management. As [Company Name] continues to develop and improve its technology, the Plastic Melter Densifier stands as a testament to the company's commitment to innovation and sustainability.In conclusion, the introduction of the Plastic Melter Densifier by [Company Name] represents a significant step forward in the effort to address the global plastic waste crisis. By offering a practical and efficient solution to the management of plastic waste, [Company Name] is not only helping businesses and municipalities reduce their environmental impact but also creating new opportunities for economic growth. As the demand for sustainable waste management solutions continues to grow, the Plastic Melter Densifier stands as a testament to the power of innovation and the potential for positive change in the field of plastic waste management.

Understanding the Cost of Extruder Machines: What You Need to Know

Cost Of Extruder MachineThe cost of an extruder machine is a crucial consideration for companies in the manufacturing and processing industries. Extruder machines are utilized in various industries for the production of a wide range of products including food items, plastic materials, rubber, and more. The cost of an extruder machine can vary depending on several factors such as size, capacity, features, and brand. One of the leading manufacturers of extruder machines is [Company Name]. With over [X] years of experience in the industry, [Company Name] has a reputation for producing high-quality and innovative extruder machines that cater to the diverse needs of their customers. As a company, [Company Name] is committed to providing their customers with state-of-the-art extruder machines that are not only efficient but also cost-effective.When it comes to the cost of extruder machines, it is important to consider the specific requirements of the manufacturing or processing operations. The cost of an extruder machine can range from a few thousand dollars to several hundred thousand dollars. The size and capacity of the machine play a significant role in determining the cost, with larger and more powerful machines typically being more expensive.In addition to size and capacity, the features and capabilities of the extruder machine can also impact its cost. Extruder machines come with a variety of features such as advanced control systems, multiple extrusion capabilities, automated functions, and more. These features can add to the overall cost of the machine but are often essential for companies looking to optimize their production processes.Furthermore, the brand of the extruder machine can also influence its cost. While there are numerous manufacturers of extruder machines in the market, established and reputable brands like [Company Name] may come with a higher price tag due to their quality, reliability, and after-sales support. However, investing in a well-known brand can also provide companies with the assurance of superior performance and longevity.It is also important to note that the cost of an extruder machine is not limited to its initial purchase price. Companies must consider additional expenses such as installation, training, maintenance, and ongoing operational costs. These factors should be carefully evaluated to ensure that the total cost of ownership of the extruder machine aligns with the company's budget and operational requirements.In conclusion, the cost of an extruder machine can vary based on factors such as size, capacity, features, and brand. As a leading manufacturer in the industry, [Company Name] is dedicated to providing their customers with cost-effective extruder machines that deliver exceptional performance and value. By understanding their specific production needs and carefully evaluating the various cost considerations, companies can make informed decisions when investing in an extruder machine that will contribute to their success and growth in the industry.

Efficient PVC Pipe Making Plant for High-Quality Production

PVC Pipe Making Plant Expands Production Capacity[Company Name], a leading manufacturer of PVC pipes and fittings, has announced plans to expand its production capacity with the establishment of a new PVC pipe making plant. The company, known for its innovative and high-quality products, aims to meet the increasing demand for PVC pipes in the construction and infrastructure sectors.The new plant, to be located in [City, Country], will utilize state-of-the-art machinery and technology to manufacture a wide range of PVC pipes, including pressure pipes, electrical conduits, and drainage pipes. With an initial investment of [amount] million, the plant is expected to have an annual production capacity of [capacity] metric tons of PVC pipes."We are excited to announce the establishment of our new PVC pipe making plant, which marks a significant milestone for our company," said [Spokesperson], CEO of [Company Name]. "This expansion reflects our commitment to meeting the growing needs of our customers and the market, and further solidifies our position as a leading player in the PVC pipe industry."The demand for PVC pipes has been steadily increasing in recent years, driven by the rapid urbanization and infrastructure development taking place in emerging economies. PVC pipes are widely used in various applications, including water distribution, sewerage, cable protection, and agricultural irrigation, due to their durability, corrosion resistance, and cost-effectiveness.[Company Name] has been at the forefront of the PVC pipe industry, offering a wide range of products that meet international quality standards. With a strong focus on research and development, the company has continuously innovated its manufacturing processes to enhance product performance and sustainability.The new PVC pipe making plant will enable [Company Name] to expand its product portfolio and offer a diverse range of PVC pipes to cater to the specific needs of different industries and applications. Additionally, the increased production capacity will allow the company to better serve its existing customers and explore new markets and business opportunities.In line with its commitment to sustainability, [Company Name] has incorporated environmentally friendly practices in the design and operation of the new plant. The utilization of energy-efficient equipment, waste minimization techniques, and responsible sourcing of raw materials will ensure that the plant operates in an eco-friendly manner.Furthermore, the new plant is expected to create job opportunities for the local community and contribute to the economic development of the region. By providing employment and supporting local suppliers and service providers, [Company Name] aims to have a positive impact on the social and economic fabric of the area.The establishment of the new PVC pipe making plant underscores [Company Name]'s dedication to staying ahead of industry trends and meeting the evolving needs of its customers. With a focus on innovation, quality, and sustainability, the company is poised to continue its upward trajectory in the PVC pipe market and make a significant contribution to the development of infrastructure worldwide.

Effective Ways to Recycle Soft Plastics

[Company Logo]Soft Plastic Recycling: A Step Towards Sustainable Future In today's fast-paced and consumer-driven world, the importance of recycling and sustainability cannot be overstated. As the global concern for environmental issues continues to grow, companies are striving to find innovative solutions to reduce their carbon footprint and promote a more sustainable way of doing business. One such company that is leading the charge in soft plastic recycling is [Company Name].[Company Name] is a pioneering leader in the field of environmental sustainability, with a strong focus on recycling and reducing waste. The company has developed cutting-edge technology and processes to recycle soft plastics, which are often difficult to recycle due to their composition and properties. By utilizing state-of-the-art equipment and machinery, [Company Name] has been able to process and recycle soft plastics, turning them into high-quality reusable materials.The process of soft plastic recycling begins with collecting and sorting the plastic waste. This is followed by cleaning, shredding, and then melting the plastic to form pellets, which can be used to manufacture new products. The company's advanced recycling facilities are designed to handle large volumes of soft plastic waste, ensuring maximum efficiency and minimal environmental impact.In addition to its recycling efforts, [Company Name] is committed to raising awareness about the importance of recycling and encouraging individuals and businesses to participate in sustainable practices. The company has implemented various educational and outreach programs to engage the community and promote a culture of recycling and environmental responsibility.One of the key initiatives of [Company Name] is its collaboration with local governments and non-profit organizations to establish collection points for soft plastic waste. These collection points are strategically placed in high-traffic areas such as supermarkets, shopping malls, and public spaces, making it convenient for people to dispose of their soft plastic waste in an environmentally responsible manner. By making recycling accessible and easy, [Company Name] is empowering individuals to take an active role in preserving the environment.Furthermore, [Company Name] has forged partnerships with major manufacturers and businesses to create a closed-loop system for recycling soft plastics. Through these partnerships, the company is able to collect, recycle, and reutilize soft plastics in the production process, effectively closing the loop and reducing the amount of plastic waste that ends up in landfills or oceans.The impact of [Company Name]'s efforts in soft plastic recycling goes beyond environmental benefits. By diverting soft plastics from landfills and repurposing them into reusable materials, the company is contributing to the circular economy and reducing the demand for virgin raw materials. This not only conserves natural resources but also helps to lower the carbon footprint associated with the production of new plastics.As a result of its commitment to sustainability and environmental stewardship, [Company Name] has been recognized for its outstanding contributions to soft plastic recycling. The company has received accolades and awards from industry organizations and government agencies, affirming its position as a leader in sustainable business practices.In conclusion, [Company Name] is at the forefront of soft plastic recycling, demonstrating a steadfast dedication to environmental sustainability and responsible waste management. Through its innovative recycling processes, educational initiatives, and strategic partnerships, the company is making a significant impact in reducing plastic waste and promoting a more sustainable future. With its unwavering commitment to the environment, [Company Name] is setting a shining example for businesses across the globe, proving that sustainability and profitability can go hand in hand.

Efficient HDPE Bottle Washing Line for Recycling Process

HDPE Bottle Washing Line Revolutionizes Plastic RecyclingIn an effort to combat the growing plastic pollution crisis, {Company Name} has introduced a cutting-edge HDPE bottle washing line that promises to revolutionize the plastic recycling industry.{Company Name} is a leading manufacturer of plastic recycling equipment, specializing in the design and production of state-of-the-art machinery for processing a wide range of plastic materials. With a strong commitment to environmental sustainability, the company has invested heavily in research and development to create innovative solutions for the recycling industry.The new HDPE bottle washing line represents a significant advancement in plastic recycling technology. Designed to handle a large volume of HDPE (high-density polyethylene) bottles, the washing line is capable of efficiently and effectively removing contaminants and preparing the bottles for the recycling process.Unlike traditional washing methods, which can be time-consuming and require significant manual labor, the HDPE bottle washing line is fully automated, reducing the need for human intervention and streamlining the recycling process. The line incorporates advanced sorting, shredding, washing, and drying technologies to ensure that the recycled plastic meets the highest standards of cleanliness and purity.One of the key features of the HDPE bottle washing line is its ability to remove labels and adhesives from the bottles, which are often difficult to eliminate with conventional washing methods. This eliminates the need for manual label removal, further improving the efficiency of the recycling process.The introduction of the HDPE bottle washing line comes at a critical time, as the global plastic pollution crisis continues to escalate. With millions of tons of plastic waste entering landfills and oceans every year, there is an urgent need for more effective recycling solutions.By providing a high-capacity, automated system for processing HDPE bottles, {Company Name} is helping to address the challenges of plastic pollution and promote a more sustainable approach to plastic waste management. The company's commitment to innovation and environmental responsibility is evident in the development of the HDPE bottle washing line, which represents a significant advancement in the field of plastic recycling.In addition to the environmental benefits of the HDPE bottle washing line, the technology also offers economic advantages for recycling facilities. By automating the washing process and improving the efficiency of plastic recycling, the line can help facilities reduce operating costs and increase their overall output of high-quality recycled plastic material.{Company Name} is dedicated to supporting the global effort to reduce plastic waste and promote a circular economy for plastics. The introduction of the HDPE bottle washing line is a testament to the company's ongoing commitment to developing innovative solutions that address the environmental challenges of plastic pollution.As the demand for recycled plastic continues to grow, {Company Name} is poised to play a crucial role in advancing the recycling industry and contributing to a more sustainable future. With the introduction of the HDPE bottle washing line, the company has positioned itself as a leader in the field of plastic recycling technology, providing an advanced solution that has the potential to make a significant impact on the global plastic pollution crisis.

Revolutionizing Extrusion Technology: Discover the Advantages of Counter Rotating Twin Screw Extruders

[Company Name] Launches Cutting-Edge Counter Rotating Twin Screw Extruder Enhancing Production Efficiency[date][City], [State] - [Company Name], a leading provider of cutting-edge manufacturing solutions, is thrilled to announce the launch of its latest innovation - a state-of-the-art Counter Rotating Twin Screw Extruder. This advanced extruder, developed by [Company Name]'s team of skilled engineers and scientists, promises to revolutionize the production process in various industries.The new Counter Rotating Twin Screw Extruder is designed to improve production efficiency, reduce processing times, and enhance the quality of final products. With its innovative features and robust design, this extruder is set to become an essential tool for manufacturers across the globe.One of the key advantages of the Counter Rotating Twin Screw Extruder is its ability to handle a wide range of materials, making it suitable for diverse industries such as plastics, food processing, pharmaceuticals, and petrochemicals. The extruder's versatility allows manufacturers to easily adapt their production processes, saving time and resources.The extruder incorporates advanced technology, featuring a counter-rotating twin screw system. This unique design ensures optimal mixing and dispersion of materials, resulting in a more consistent and uniform final product. The efficient screw system also minimizes material degradation and heat generation, reducing production costs and improving product quality.Additionally, the Counter Rotating Twin Screw Extruder offers precise control over various process parameters, including temperature, speed, and pressure. This level of control allows manufacturers to achieve highly accurate and repeatable production results, meeting the strictest quality standards.Furthermore, the extruder is equipped with intelligent automation and monitoring systems, which provide real-time data on the production process. This allows operators to identify and address any issues promptly, ensuring minimal downtime and maximizing productivity.[Company Name]'s commitment to sustainability is evident in the extruder's energy-efficient design. By optimizing energy consumption and minimizing waste generation, this innovation aligns with the company's broader environmental goals. Manufacturers adopting this extruder can reduce their carbon footprint while enhancing their manufacturing capabilities.The Counter Rotating Twin Screw Extruder is the result of [Company Name]'s extensive research and development efforts. The company, founded in [year], has established itself as a trusted resource for cutting-edge manufacturing solutions. With a team of skilled engineers and scientists, [Company Name] consistently strives to deliver innovative technologies that meet the evolving needs of global industries."We are excited to introduce our latest innovation, the Counter Rotating Twin Screw Extruder," said [Spokesperson Name], CEO of [Company Name]. "This technological breakthrough will revolutionize production processes, boosting efficiency, product quality, and sustainability. We believe that this extruder will empower manufacturers and contribute to a more sustainable future for various industries."As manufacturers worldwide seek ways to improve productivity and reduce costs, [Company Name]'s Counter Rotating Twin Screw Extruder provides a compelling solution. This state-of-the-art extruder offers enhanced process control, versatility, and efficiency, ultimately helping companies gain a competitive edge in their respective markets.For more information about [Company Name] and its comprehensive range of manufacturing solutions, please visit [website].