High-quality PVC Pipe Machine for Efficient Production - Find Out More!

By:Admin

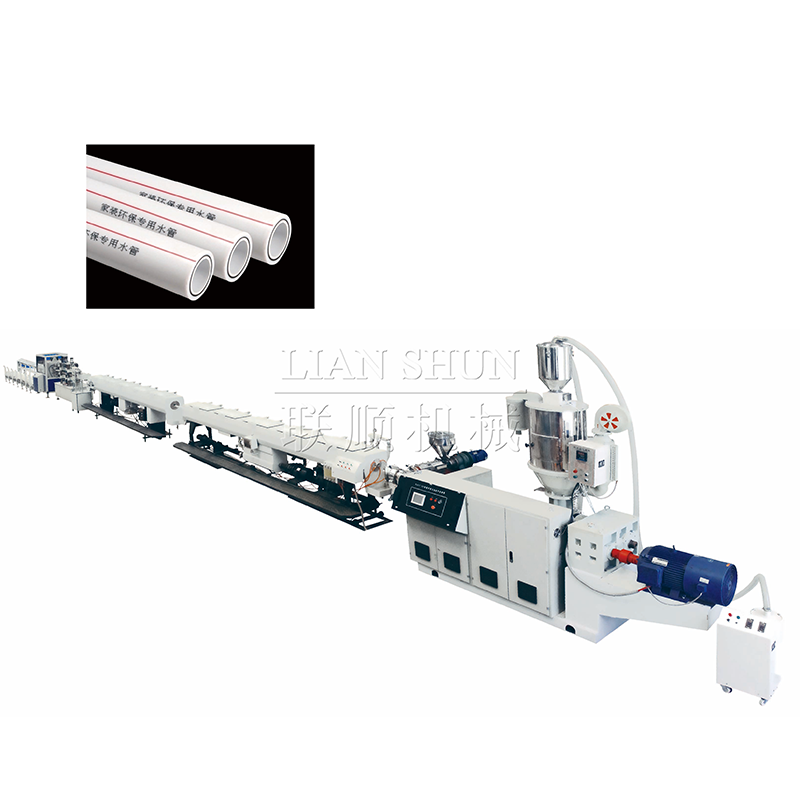

The manufacturing industry has seen significant advancements over the years, with new technologies constantly emerging to improve efficiency and productivity. One such innovation is the pipe PVC machine developed by {Company Name}.

{Company Name} has been a leading manufacturer of industrial machinery for over two decades. The company specializes in the design and production of automated equipment for various industries, including construction, agriculture, and packaging. With a focus on innovation and quality, {Company Name} has gained a reputation for providing cutting-edge solutions that meet the needs of modern manufacturing.

The latest offering from {Company Name} is the pipe PVC machine, a state-of-the-art production system designed to revolutionize the manufacturing of PVC pipes. This machine is equipped with advanced technology to streamline the production process and improve the overall quality of the end product. With its innovative features and high efficiency, the pipe PVC machine is poised to make a significant impact on the industry.

One of the key features of the pipe PVC machine is its fully automated operation, which reduces the need for manual labor and minimizes the risk of human error. This not only improves productivity but also ensures consistent and precise manufacturing, leading to higher-quality pipes. In addition, the machine is equipped with sensors and monitoring systems to detect and correct any issues in real time, further enhancing its reliability and performance.

Furthermore, the pipe PVC machine is highly versatile and can accommodate a wide range of pipe sizes and specifications. This flexibility allows manufacturers to produce pipes for various applications, from plumbing and drainage to irrigation and industrial uses. With the ability to adapt to different production requirements, the machine offers a cost-effective solution for businesses of all sizes.

In terms of sustainability, the pipe PVC machine is designed to minimize waste and energy consumption, contributing to a more environmentally friendly manufacturing process. By optimizing material usage and reducing the need for manual intervention, the machine helps lower the overall environmental impact of PVC pipe production. This aligns with {Company Name}'s commitment to sustainability and responsible manufacturing practices.

{Company Name} prides itself on its comprehensive customer support, offering installation, training, and ongoing maintenance services for the pipe PVC machine. This ensures that clients can maximize the benefits of the machine and operate it with confidence. In addition, the company's dedicated technical team is readily available to provide assistance and address any concerns, reaffirming their dedication to customer satisfaction.

The introduction of the pipe PVC machine marks a significant milestone for {Company Name} and the manufacturing industry as a whole. With its cutting-edge technology, advanced features, and commitment to sustainability, the machine is set to elevate the standards of PVC pipe production. As the industry continues to evolve, {Company Name} remains at the forefront of innovation, driving positive change and delivering solutions that empower businesses to thrive in a competitive market.

In conclusion, the pipe PVC machine from {Company Name} represents a game-changing advancement in manufacturing technology. With its focus on automation, versatility, and sustainability, the machine is poised to reshape the production of PVC pipes and set new standards for efficiency and quality. As manufacturers seek to optimize their operations and meet the demands of the market, {Company Name} remains a trusted partner, providing innovative solutions that propel the industry forward.

Company News & Blog

Top Dating Apps for LGBTQ+ Community

Grindr, a popular dating app for LGBTQ+ community, has recently announced a new feature that will revolutionize the way people connect with each other. The app, which is known for its inclusivity and user-friendly interface, has introduced a new feature that allows users to connect with each other based on their location, interests, and preferences.Grindr is a social networking app for the LGBTQ+ community that allows users to connect with other like-minded individuals. The app was launched in 2009 and has since gained a large and loyal following. It is available on both iOS and Android and has been downloaded by millions of users worldwide.The new feature, which is called "Explore," allows users to connect with others based on their location and interests. This means that users can now see who is nearby and connect with them based on their common interests and preferences. This feature is a game-changer for the app, as it allows users to connect with others in a more meaningful and efficient way.In addition to the new "Explore" feature, Grindr has also introduced a new chat tool that allows users to communicate with each other in real-time. This chat tool is designed to make it easier for users to connect with each other and build meaningful relationships. The new chat tool is user-friendly and allows for seamless communication between users.Grindr has always been committed to creating a safe and inclusive space for the LGBTQ+ community, and this new feature is no exception. The app has strict guidelines and policies in place to ensure that users feel comfortable and safe while using the app. The new feature is designed to make it easier for users to connect with each other while also prioritizing their safety and security.Speaking about the new feature, the CEO of Grindr, {CEO Name}, expressed his excitement about the new update. He stated, "We are constantly looking for ways to improve the user experience on Grindr, and the new 'Explore' feature is a testament to that. We want to make it easier for our users to connect with each other and build meaningful relationships, and we believe that this new feature will do just that."The new feature has already been met with positive feedback from users, who have expressed their excitement about the improved user experience. Many users have praised the app for its innovation and commitment to creating a safe and inclusive environment for the LGBTQ+ community.In addition to the new feature, Grindr has also announced plans for further updates and improvements in the coming months. The company is dedicated to staying at the forefront of technology and innovation, and users can expect to see more exciting features in the near future.Overall, the new "Explore" feature is poised to revolutionize the way people connect with each other on Grindr. With its user-friendly interface and commitment to creating a safe and inclusive space for the LGBTQ+ community, Grindr continues to be a leader in the world of social networking apps. Users can look forward to a more seamless and meaningful experience as they connect with others on the app.

Benefits and Uses of Small Twin Screw Extruders

Title: Small Twin Screw Extruder: Revolutionizing Polymer Processing Industry Introduction:In today's fast-paced industrial world, efficient and effective machinery plays a crucial role in driving growth and innovation. Addressing the increasing demand for polymer processing with enhanced productivity and versatility, {Company Name}'s Small Twin Screw Extruder is transforming the industry. This state-of-the-art machine combines cutting-edge technology with superior build quality, taking polymer processing to new heights. Advancement in Polymer Processing:Polymer processing technology has evolved significantly over the years, with extrusion playing a key role in manufacturing various products. The Small Twin Screw Extruder by {Company Name} exemplifies the latest advancements in this field. As the demand for polymer-based applications continues to grow in sectors such as packaging, construction, and automotive, the extruder offers unparalleled efficiency, precision, and flexibility.Key Features and Benefits:1. Compact Design: The Small Twin Screw Extruder boasts a compact structure, making it suitable for use in constrained spaces. Its ergonomic design ensures ease of use and maintenance, saving both time and effort.2. High Efficiency: The extruder is equipped with twin screws that operate in perfect sync, facilitating a highly efficient and streamlined extrusion process. This results in improved productivity and reduced energy consumption, ultimately leading to cost savings for manufacturers.3. Versatility: From simple polymer compounding to intricate product development, the Small Twin Screw Extruder caters to a diverse range of applications. Its adjustable parameters allow manufacturers to customize the machine's settings to meet their specific requirements, enabling enhanced product development and quality control.4. Superior Mixing Capability: The machine's twin screws provide exceptional mixing and dispersion of various additives, fillers, and additives, ensuring homogeneous product output. This feature enables manufacturers to achieve consistent quality and reduces material waste, resulting in significant savings.5. Enhanced Processing Control: The extruder's advanced control systems, coupled with user-friendly interfaces, empower operators to monitor and adjust process parameters with ease. Real-time data display and analysis enable quick decision-making, reducing downtime and enhancing overall efficiency.Industry Impact:The introduction of {Company Name}'s Small Twin Screw Extruder has had a profound impact on the polymer processing industry. The machine's advanced capabilities have paved the way for innovation and efficiency, transforming the way manufacturers approach polymer-based applications. With reduced production costs, enhanced product quality, and increased overall productivity, manufacturers can now meet the evolving demands of their customers more effectively.Future Prospects:The Small Twin Screw Extruder by {Company Name} is not just a testament to the present advancements in the polymer processing industry but also an indicator of its future potential. Continuous research and development efforts by {Company Name} promise further improvements in machine design, performance, and versatility. As the industry continues to demand optimized processes, customization, and material compatibility, the Small Twin Screw Extruder offers exciting possibilities for manufacturers.Conclusion:{Company Name}'s Small Twin Screw Extruder has revolutionized the polymer processing industry by combining state-of-the-art technology with unparalleled efficiency and versatility. With its compact design, high efficiency, superior mixing capability, and enhanced processing control, the extruder empowers manufacturers to produce high-quality polymer-based products while optimizing costs and resources. As the demand for polymer applications grows, {Company Name} remains committed to pushing the boundaries of innovation, driving the industry forward.

Revolutionizing Extrusion Technology: Discover the Advantages of Counter Rotating Twin Screw Extruders

[Company Name] Launches Cutting-Edge Counter Rotating Twin Screw Extruder Enhancing Production Efficiency[date][City], [State] - [Company Name], a leading provider of cutting-edge manufacturing solutions, is thrilled to announce the launch of its latest innovation - a state-of-the-art Counter Rotating Twin Screw Extruder. This advanced extruder, developed by [Company Name]'s team of skilled engineers and scientists, promises to revolutionize the production process in various industries.The new Counter Rotating Twin Screw Extruder is designed to improve production efficiency, reduce processing times, and enhance the quality of final products. With its innovative features and robust design, this extruder is set to become an essential tool for manufacturers across the globe.One of the key advantages of the Counter Rotating Twin Screw Extruder is its ability to handle a wide range of materials, making it suitable for diverse industries such as plastics, food processing, pharmaceuticals, and petrochemicals. The extruder's versatility allows manufacturers to easily adapt their production processes, saving time and resources.The extruder incorporates advanced technology, featuring a counter-rotating twin screw system. This unique design ensures optimal mixing and dispersion of materials, resulting in a more consistent and uniform final product. The efficient screw system also minimizes material degradation and heat generation, reducing production costs and improving product quality.Additionally, the Counter Rotating Twin Screw Extruder offers precise control over various process parameters, including temperature, speed, and pressure. This level of control allows manufacturers to achieve highly accurate and repeatable production results, meeting the strictest quality standards.Furthermore, the extruder is equipped with intelligent automation and monitoring systems, which provide real-time data on the production process. This allows operators to identify and address any issues promptly, ensuring minimal downtime and maximizing productivity.[Company Name]'s commitment to sustainability is evident in the extruder's energy-efficient design. By optimizing energy consumption and minimizing waste generation, this innovation aligns with the company's broader environmental goals. Manufacturers adopting this extruder can reduce their carbon footprint while enhancing their manufacturing capabilities.The Counter Rotating Twin Screw Extruder is the result of [Company Name]'s extensive research and development efforts. The company, founded in [year], has established itself as a trusted resource for cutting-edge manufacturing solutions. With a team of skilled engineers and scientists, [Company Name] consistently strives to deliver innovative technologies that meet the evolving needs of global industries."We are excited to introduce our latest innovation, the Counter Rotating Twin Screw Extruder," said [Spokesperson Name], CEO of [Company Name]. "This technological breakthrough will revolutionize production processes, boosting efficiency, product quality, and sustainability. We believe that this extruder will empower manufacturers and contribute to a more sustainable future for various industries."As manufacturers worldwide seek ways to improve productivity and reduce costs, [Company Name]'s Counter Rotating Twin Screw Extruder provides a compelling solution. This state-of-the-art extruder offers enhanced process control, versatility, and efficiency, ultimately helping companies gain a competitive edge in their respective markets.For more information about [Company Name] and its comprehensive range of manufacturing solutions, please visit [website].

High-Quality Pe Pipe Making Machine for Efficient Production

In recent years, the demand for high-quality PE pipes has been on the rise due to the increasing infrastructure development and construction projects. To cater to this demand, many companies have been investing in advanced PE pipe making machines to ensure efficient production and high-quality output.One such company that has been making waves in the industry is {Company Name}. With a strong focus on technological innovation and product quality, they have recently introduced their state-of-the-art PE pipe making machine, which is poised to revolutionize the industry.The new PE pipe making machine incorporates the latest advancements in technology to enhance the efficiency and quality of pipe production. It is equipped with advanced extrusion and molding systems that ensure precise shaping and sizing of the pipes. The machine also features a high-performance cooling system that enables rapid cooling of the pipes, resulting in improved dimensional accuracy and surface finish.Moreover, the machine is designed to handle a wide range of PE materials, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), making it versatile for various applications. It is also equipped with advanced automation and control systems, which not only streamline the production process but also ensure consistent quality of the pipes.The introduction of this cutting-edge PE pipe making machine is a testament to {Company Name}'s commitment to providing the market with innovative and high-quality products. With years of experience in the industry, they have established themselves as a leading manufacturer of plastic machinery, and this new addition to their product line further solidifies their position in the market.It is worth noting that {Company Name} has a proven track record of delivering reliable and efficient machinery to its customers. Their machines are known for their durability, precision, and low maintenance, making them a preferred choice for many businesses in the plastic manufacturing sector.In addition to their advanced machinery, {Company Name} also offers comprehensive after-sales service and technical support to ensure that their customers get the most out of their investments. This commitment to customer satisfaction has earned them a strong reputation in the industry and has contributed to their continued success.The introduction of the new PE pipe making machine by {Company Name} is expected to have a significant impact on the industry. It is set to meet the growing demand for high-quality PE pipes and provide manufacturers with the tools they need to stay ahead in a competitive market.In conclusion, the unveiling of the advanced PE pipe making machine by {Company Name} is a testament to their dedication to innovation and quality. With its cutting-edge technology and unmatched performance, this machine is poised to set new standards in the production of PE pipes. As the industry continues to evolve, {Company Name} remains at the forefront, providing solutions that meet the needs of the market and exceed the expectations of their customers.

Find plastic extruders near your location for all your needs

Plastic extruders are a key component in the manufacturing industry and play a crucial role in the production of various plastic products. These machines are used to melt and extrude raw plastic material into a continuous profile, which is then used to create a wide range of products such as pipes, tubing, and profiles.In the market for plastic extruders, there is a growing demand for high-quality machines that are reliable, efficient, and cost-effective. As a result, many companies are searching for reputable and reliable manufacturers of plastic extruders that are located near their operational base. One such manufacturer that has been gaining attention in the industry is {}. Founded in {}, the company has established itself as a leading provider of plastic extrusion equipment and has built a strong reputation for delivering top-quality machines and excellent customer service.The company's extensive product line includes a variety of plastic extruders, ranging from single screw extruders to co-extruders, and is suitable for producing a wide range of plastic products. These machines are designed to meet the diverse needs of their customers and are known for their efficiency, reliability, and durability.One of the key factors that set {} apart from other manufacturers is their commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking new ways to enhance their machines' performance and capabilities. This dedication to innovation has allowed {} to stay at the forefront of technological advancements in the industry and ensures that their customers have access to state-of-the-art equipment.In addition to their focus on innovation, {} also places a strong emphasis on quality control and adherence to industry standards. All of their machines undergo rigorous testing and inspection procedures to ensure that they meet the highest quality standards. This commitment to quality has earned the company various certifications and accreditations, solidifying their position as a trusted and reputable manufacturer in the industry.Furthermore, {} takes pride in its customer-centric approach and is dedicated to providing exceptional service to its clients. The company has a team of knowledgeable and experienced professionals who are readily available to provide technical support, guidance, and training to their customers. This level of support allows their clients to maximize the performance and efficiency of their plastic extruders, ultimately leading to increased productivity and profitability.It's also worth noting that {} is committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize its environmental impact and reduce waste in its manufacturing processes. This demonstrates their commitment to creating a greener and more sustainable future for the industry.As a result of these factors, {} has been attracting attention from companies in search of reliable and reputable manufacturers of plastic extruders. Their dedication to quality, innovation, and customer satisfaction has set them apart as a leading provider of plastic extrusion equipment.With the increasing demand for high-quality plastic extruders, {} is well-positioned to meet the needs of the industry and continue to grow its presence in the market. With a strong focus on innovation, quality, and customer service, the company is poised to remain a top choice for companies seeking reliable and efficient plastic extrusion equipment.In conclusion, the demand for plastic extruders continues to grow, and companies are constantly searching for reputable manufacturers that can provide high-quality and reliable machines. {}. With its commitment to innovation, quality, and customer satisfaction, the company has established itself as a leading provider of plastic extrusion equipment and is well-positioned to meet the evolving needs of the industry.

Guide to PPR Pipe Lines: The Ultimate Solution for Plumbing Systems

In a major development for the water supply and distribution system, a new PPR pipe line has been introduced by a leading manufacturer in the industry. This innovative product promises to bring a host of benefits to the construction and plumbing sectors, ensuring durability, efficiency, and overall cost-savings for various infrastructure projects.The PPR pipe line, which is manufactured by a company known for its cutting-edge solutions in the field of water and gas distribution systems, is set to revolutionize the way in which pipes are utilized in construction projects. The company has a strong track record of providing high-quality products that are designed to meet the evolving needs of the industry, and this latest offering is no exception.PPR, which stands for polypropylene random copolymer, is a type of plastic that is increasingly being used for piping systems due to its numerous advantages over traditional materials such as metal and PVC. The material is known for its resistance to high temperatures and pressure, making it ideal for use in hot and cold water supply lines, as well as in industrial and chemical pipelines. Additionally, PPR pipes are highly resistant to corrosion, ensuring a longer lifespan and lower maintenance costs.In addition to its physical properties, PPR pipes are also known for their ease of installation. These pipes can be easily joined using heat fusion, which creates a seamless and leak-proof connection, eliminating the need for additional fittings and reducing the risk of water leakage. This not only makes the installation process faster and more efficient, but also ensures a more reliable and durable piping system.Furthermore, the lightweight nature of PPR pipes makes them easier to handle and transport, reducing the overall labor and transportation costs associated with construction projects. This, combined with the material's long lifespan and low maintenance requirements, makes PPR pipes a cost-effective solution for developers and contractors looking to improve the efficiency and sustainability of their projects.The introduction of this new PPR pipe line by the company reflects its commitment to innovation and its ongoing efforts to provide the industry with advanced solutions that meet the highest standards of quality and performance. The company has a strong focus on research and development, and has invested significantly in state-of-the-art manufacturing processes to ensure that its products are at the forefront of technological advancement.With a strong emphasis on sustainability and environmental responsibility, the company ensures that its PPR pipe line is manufactured using eco-friendly processes and materials, contributing to the overall goal of reducing the industry's carbon footprint. This aligns with the growing trend towards sustainable construction practices, making the company a preferred choice for developers and contractors who prioritize environmental stewardship.In conclusion, the introduction of the new PPR pipe line by the company marks a significant breakthrough in the field of water supply and distribution systems. With its superior physical properties, ease of installation, and cost-effectiveness, PPR pipes are set to become the preferred choice for a wide range of construction projects. As the industry continues to evolve, the company remains at the forefront of innovation, providing cutting-edge solutions that meet the evolving needs of the market and contribute to the development of a more sustainable built environment.

How Plastic Pipe Extruders are Shaping the Manufacturing Industry

Plastic Pipe Extruder Unveils Groundbreaking Innovation in Pipeline TechnologyThe plastic pipe extrusion industry is rapidly evolving, and leading the way in this technological revolution is [Company Name], a global leader in the manufacturing of high-quality plastic pipe products. With a commitment to innovation and sustainability, [Company Name] has recently unveiled their latest groundbreaking innovation in pipeline technology that is set to revolutionize the industry.The newly developed product, which leverages state-of-the-art extrusion technology, promises to deliver unparalleled performance and durability, while also addressing the growing concerns for environmental sustainability. Unlike traditional metal pipes, the plastic pipes produced by [Company Name] are lightweight, corrosion-resistant, and highly cost-effective, making them an ideal solution for a wide range of applications, including water distribution, sewer systems, and industrial piping.[Company Name] has long been recognized for its expertise in plastic pipe extrusion, boasting a rich history of innovation and a proven track record of delivering superior products to a global customer base. With a dedicated team of research and development experts, the company has continually pushed the boundaries of what is possible in the world of plastic pipe manufacturing.In addition to their commitment to technological advancement, [Company Name] also places a strong emphasis on sustainability and environmental responsibility. The newly developed plastic pipes are made from high-quality, recyclable materials, ensuring that the environmental impact of their production and usage is minimized. This aligns with the company's broader mission to promote a more sustainable and eco-friendly approach to pipeline infrastructure.Furthermore, [Company Name] has implemented stringent quality control measures throughout the production process, ensuring that each plastic pipe that rolls off their assembly line meets the highest standards of excellence. This dedication to quality has earned the company a sterling reputation within the industry, with customers around the world trusting [Company Name] to provide reliable and long-lasting pipeline solutions.With the unveiling of their latest innovation, [Company Name] is poised to reinforce its position as an industry leader in plastic pipe extrusion. The new product is expected to set a new benchmark for performance and reliability, offering customers a cutting-edge solution that meets the demands of modern infrastructure projects.Commenting on the launch of the new product, [Company Name]'s CEO expressed his confidence in the capabilities of the innovative plastic pipe extrusion technology, stating, "We are proud to introduce this groundbreaking innovation to the market. Our team has worked tirelessly to develop a product that not only outperforms traditional pipeline materials but also aligns with our commitment to sustainability. We believe that this innovation will have a transformative impact on the industry, and we are excited to see the positive outcomes it will bring to our customers and the environment."As the global demand for high-quality, sustainable pipeline solutions continues to grow, [Company Name] is well-positioned to meet the evolving needs of the market. Their dedication to innovation, quality, and environmental responsibility sets them apart as a leading force in the plastic pipe extrusion industry, and their latest breakthrough is a testament to their ongoing pursuit of excellence.In conclusion, the unveiling of [Company Name]'s groundbreaking innovation in pipeline technology represents a significant milestone in the evolution of the plastic pipe extrusion industry. Through their commitment to innovation, sustainability, and quality, [Company Name] continues to lead the way in providing cutting-edge solutions for infrastructure projects around the world. With their latest product set to redefine the standards for pipeline performance and durability, [Company Name] is undeniably shaping the future of the industry.

PVC Pipe Manufacturing Unit Experiences Growth in Production

PVC Pipe Manufacturing Unit to Enhance Production CapacityWith the ever-growing demand for high-quality PVC pipes in the construction and infrastructure sectors, {Company Name} is proud to announce the expansion of its PVC pipe manufacturing unit. The company has been a leading player in the industry for over two decades, known for its commitment to innovation, quality, and customer satisfaction.The expansion of the PVC pipe manufacturing unit comes as a response to the increasing demand for PVC pipes in various applications such as water supply, drainage, irrigation, and sewerage. With the new and improved production capacity, {Company Name} aims to meet the growing needs of its customers while maintaining its uncompromising standards of product quality.The upgraded manufacturing unit is equipped with state-of-the-art machinery and technology, designed to enhance the efficiency and precision of the production process. This includes advanced extrusion lines, automated cutting and packaging systems, and quality control measures at every stage of production. These advancements will not only increase the overall output of PVC pipes but also ensure that each product meets the company's stringent quality standards.In addition to increasing production capacity, the expansion of the PVC pipe manufacturing unit will also create new employment opportunities, contributing to the local economy and furthering the company's commitment to social responsibility. {Company Name} has always placed importance on fostering a positive impact on the communities in which it operates, and the expansion of the manufacturing unit is a testament to this commitment.Furthermore, the company has also invested in research and development to innovate and introduce new product lines that cater to the evolving needs of its customers. This includes the development of specialized PVC pipes that offer enhanced durability, corrosion resistance, and environmental sustainability. With a focus on sustainability and environmental responsibility, {Company Name} is dedicated to providing products that not only meet industry standards but also contribute to a greener and more efficient infrastructure.The expansion of the PVC pipe manufacturing unit is a significant milestone for {Company Name} and underscores its position as a leader in the PVC pipe industry. The company's dedication to quality, innovation, and customer satisfaction has set it apart in a competitive market, and the expansion of its manufacturing capabilities reaffirms its commitment to meeting the growing demands of its customers.As {Company Name} continues to grow and evolve, it remains dedicated to upholding its core values of excellence, integrity, and sustainability. The expansion of the PVC pipe manufacturing unit is a reflection of these values and will enable the company to better serve its customers and contribute to the development of crucial infrastructure projects.In conclusion, the expansion of the PVC pipe manufacturing unit at {Company Name} represents a significant step forward for the company and the industry as a whole. With increased production capacity, advanced technology, and a focus on innovation, {Company Name} is well-positioned to meet the growing demand for high-quality PVC pipes and further solidify its reputation as a leader in the market. As the company continues to invest in its manufacturing capabilities, it remains committed to delivering exceptional products and driving positive change in the infrastructure and construction sectors.

Efficient Plastic Pelletizer for High-Quality Production

Plastic manufacturing companies around the world are constantly looking for innovative solutions to improve their production processes and reduce waste. One company that has been at the forefront of developing cutting-edge solutions for the plastics industry is {}.{} is a leading manufacturer of plastic processing machinery and equipment, specializing in the design and production of plastic pelletizers. The company has a strong reputation for its high-quality products and innovative technologies, and it has been dedicated to helping plastic manufacturers streamline their production processes and minimize waste generation.One of {}'s most recent innovations is the development of a state-of-the-art plastic pelletizer that is revolutionizing the way plastic manufacturers process and recycle their materials. The new pelletizer is designed to efficiently and effectively convert plastic waste into high-quality pellets that can be used in a wide range of applications, including the manufacturing of new plastic products.The plastic pelletizer is equipped with advanced features and technologies that set it apart from traditional pelletizing equipment. It is designed to handle a wide variety of plastic materials, including both virgin and recycled plastics, and it can produce pellets of consistent size and quality. This level of precision and consistency is crucial for manufacturers who rely on high-quality pellets to produce their products.In addition to its advanced capabilities, the plastic pelletizer also offers enhanced energy efficiency and production capacity. Thanks to its innovative design and engineering, the pelletizer is able to process larger quantities of plastic materials in a shorter amount of time, reducing the overall energy consumption and labor costs associated with pelletizing operations.Furthermore, the plastic pelletizer is designed with a focus on sustainability and environmental responsibility. By enabling manufacturers to efficiently recycle their plastic waste and transform it into reusable pellets, the pelletizer plays a key role in reducing the environmental impact of plastic production and consumption. This aligns with {}'s commitment to developing eco-friendly solutions for the plastics industry.Another key advantage of the plastic pelletizer is its versatility. It can be customized to meet the specific needs and requirements of different plastic manufacturers, allowing them to optimize the pelletizing process for their unique production workflows. This level of flexibility is invaluable for companies that produce a wide range of plastic products and need a pelletizer that can adapt to their changing needs.The plastic pelletizer is already generating significant interest and excitement within the plastics industry, with many manufacturers recognizing the potential benefits it offers for their operations. By investing in this innovative technology, companies can improve their production processes, reduce waste, and contribute to a more sustainable and circular economy.As {} continues to lead the way in developing advanced solutions for the plastics industry, the company remains dedicated to supporting manufacturers in their efforts to improve efficiency, reduce environmental impact, and achieve their production goals. With its new plastic pelletizer, {} is poised to make a significant impact on the way plastic materials are processed and recycled, paving the way for a more sustainable and resource-efficient future for the plastics industry.

Highly Efficient and Precise PVC Pipe Cutter Machine for Your Industrial Needs

Pvc Pipe Cutter Machine Revolutionizing the Pipe Cutting IndustryIn today’s fast-paced world, efficiency is key. Whether you are a professional in the plumbing industry or a DIY enthusiast, having the right tools for the job can make all the difference. With that in mind, a new player has emerged in the pipe cutting industry – the Pvc Pipe Cutter Machine from [Company Name].[Company Name] is a leading manufacturer of innovative cutting and shaping tools, with a focus on providing high-quality, reliable products for professionals and hobbyists alike. Founded in [year], the company has quickly gained a reputation for excellence in the field, and the Pvc Pipe Cutter Machine is a testament to their commitment to innovation and customer satisfaction.The Pvc Pipe Cutter Machine is a game-changer in the industry, offering a range of features that set it apart from traditional pipe cutting methods. With its precision cutting capabilities, the machine is able to cut through PVC pipes with ease, resulting in clean, smooth cuts every time. This eliminates the need for additional finishing work, saving time and energy for the user.One of the key features of the Pvc Pipe Cutter Machine is its versatility. It is designed to accommodate a wide range of pipe sizes, making it suitable for various applications. Whether you are working on a small plumbing project at home or a large-scale industrial job, this machine has you covered.In addition to its cutting capabilities, the Pvc Pipe Cutter Machine is also incredibly user-friendly. The intuitive design and easy-to-use controls make it accessible to users of all skill levels, while the durable construction ensures long-term reliability. This combination of ease of use and durability makes the Pvc Pipe Cutter Machine a valuable addition to any toolkit.Furthermore, safety is a top priority for [Company Name], and the Pvc Pipe Cutter Machine reflects this commitment. The machine is equipped with safety features to prevent accidents and ensure the well-being of the user. This includes protective guards and mechanisms to minimize the risk of injury during operation.Overall, the Pvc Pipe Cutter Machine is a testament to [Company Name]'s dedication to providing innovative, high-quality solutions for their customers. By combining precision cutting, versatility, user-friendliness, durability, and safety, this machine raises the bar for pipe cutting tools.The Pvc Pipe Cutter Machine has already made waves in the industry, receiving praise from professionals and enthusiasts alike. Users appreciate the time and effort it saves, as well as the consistent, high-quality results it delivers. With its growing popularity, it is clear that the Pvc Pipe Cutter Machine is set to become a staple in the pipe cutting industry.In conclusion, the Pvc Pipe Cutter Machine from [Company Name] is a game-changer in the pipe cutting industry. With its precision cutting capabilities, versatility, user-friendly design, durability, and safety features, it has set a new standard for pipe cutting tools. Whether you are a professional in the field or a hobbyist tackling a home project, the Pvc Pipe Cutter Machine is sure to make a positive impact on your work.