Innovative Film Pelletizing System Revolutionizes Plastic Waste Recycling

By:Admin

FPS is a leading company in the film pelletizing industry with a strong track record of delivering cutting-edge solutions to its customers. With a focus on innovation and sustainability, FPS is committed to developing products and solutions that not only meet the needs of its customers but also contribute to a more sustainable and environmentally friendly future.

The new Film Pelletizing System is the latest addition to FPS's extensive portfolio of products. It is designed to offer a comprehensive solution for film pelletizing, offering state-of-the-art technology that ensures high-quality pellets with minimal waste. The system is designed to cater to a wide range of film materials, including LDPE, HDPE, LLDPE, and other types of plastic films. With its flexibility and versatility, the system can be easily integrated into existing production lines, making it a cost-effective and efficient solution for film pelletizing.

One of the key features of the Film Pelletizing System is its ability to produce uniform and high-quality pellets. The system is equipped with advanced technology that ensures precise cutting and shaping of the pellets, resulting in consistent size and shape. This not only improves the quality of the pellets but also increases the efficiency of the production process.

Moreover, the Film Pelletizing System is designed to minimize waste, making it a sustainable solution for film pelletizing. The system utilizes advanced technology to reduce the amount of trim and scrap generated during the pelletizing process, leading to a significant reduction in waste. This not only helps companies save on raw material costs but also contributes to a more sustainable and environmentally friendly production process.

In addition to its quality and sustainability features, the Film Pelletizing System is also designed for ease of use and maintenance. The system is equipped with user-friendly controls and interfaces, making it easy for operators to monitor and adjust the production process. Furthermore, the system is designed for reliability and durability, requiring minimal maintenance and ensuring long-term performance.

The introduction of the Film Pelletizing System is a testament to FPS's commitment to innovation and sustainability. The system is set to redefine the film pelletizing industry by offering a comprehensive solution that addresses the needs of manufacturers while minimizing environmental impact. With its high-quality pellets, reduced waste, and ease of use, the new system is poised to become a game-changer in the film pelletizing industry.

The Film Pelletizing System has already garnered attention from industry experts and customers alike. With its innovative technology and sustainable features, the new system has been lauded for its potential to transform the film pelletizing industry. As the demand for sustainable and efficient production solutions continues to grow, FPS's new Film Pelletizing System is well-positioned to meet the needs of manufacturers and contribute to a more sustainable future.

In conclusion, the introduction of the Film Pelletizing System represents a significant milestone for FPS and the film pelletizing industry. With its advanced technology, sustainability features, and ease of use, the new system is poised to revolutionize the way film pelletizing is done. As the industry continues to evolve, FPS remains committed to delivering innovative and sustainable solutions that meet the needs of its customers and contribute to a more sustainable future.

Company News & Blog

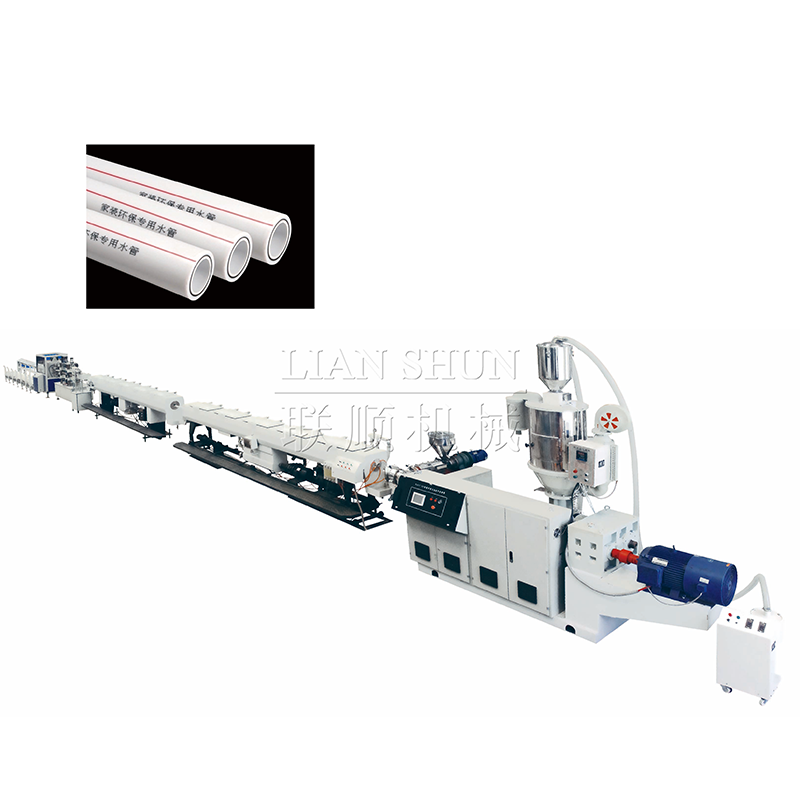

High-Quality PE Pipe Production Line for Efficient Manufacturing

The demand for high-quality and efficient PE pipe production lines has been steadily increasing in the global market. As a response to this demand, {Company Name}, a leading manufacturer of plastic machinery and equipment, has recently launched a state-of-the-art PE pipe production line.The new PE pipe production line from {Company Name} is designed to meet the growing demand for high-quality and cost-effective PE pipes in various industries such as agriculture, construction, and water supply. The production line is equipped with advanced technology and innovative features that ensure consistent and reliable performance, making it an ideal choice for manufacturers looking to enhance their production capabilities.One of the key features of the new PE pipe production line is its high production capacity, which allows for the efficient and rapid manufacturing of PE pipes in various sizes and specifications. This is especially beneficial for companies that require large volumes of PE pipes to meet the demands of their customers. Additionally, the production line is designed to minimize energy consumption and maximize production efficiency, resulting in lower operating costs and higher overall productivity.In addition to its high production capacity, the PE pipe production line from {Company Name} also offers exceptional flexibility and customization options. This means that manufacturers can tailor the production line to meet their specific requirements, ensuring that they can produce PE pipes that meet the highest industry standards and customer expectations.Moreover, the PE pipe production line is also equipped with advanced quality control systems that monitor the production process to ensure the consistent quality of the pipes. This is crucial for manufacturers who require PE pipes that meet strict industry standards for strength, durability, and chemical resistance.As a company with a long-standing reputation for excellence in the field of plastic machinery and equipment, {Company Name} is committed to providing its customers with top-of-the-line products and exceptional customer service. The launch of the new PE pipe production line is a testament to the company's dedication to innovation and continuous improvement, as well as its commitment to meeting the evolving needs of its customers in the global market.To further support its customers, {Company Name} also offers comprehensive technical support and after-sales services for the new PE pipe production line. This includes installation, training, maintenance, and troubleshooting, ensuring that customers can maximize the performance and lifespan of their equipment.In conclusion, the launch of the new PE pipe production line from {Company Name} represents a significant advancement in the industry, offering manufacturers a reliable and efficient solution for producing high-quality PE pipes. With its advanced technology, high production capacity, flexibility, and exceptional quality control, the new production line is set to become a game-changer for companies looking to enhance their manufacturing capabilities and meet the growing demand for PE pipes in various industries. As a trusted partner in the global market, {Company Name} is well-positioned to support its customers with industry-leading equipment and services, solidifying its reputation as a preferred choice for plastic machinery and equipment.

Innovative Film Pelletizing System Revolutionizes Plastic Waste Recycling

Film Pelletizing System (FPS) has recently introduced a groundbreaking technology that is revolutionizing the film pelletizing industry. Their innovative system not only produces high-quality pellets but also helps reduce waste and increase production efficiency. This new technology is set to change the way film pelletizing is done and is creating a buzz in the industry.FPS is a leading company in the film pelletizing industry with a strong track record of delivering cutting-edge solutions to its customers. With a focus on innovation and sustainability, FPS is committed to developing products and solutions that not only meet the needs of its customers but also contribute to a more sustainable and environmentally friendly future.The new Film Pelletizing System is the latest addition to FPS's extensive portfolio of products. It is designed to offer a comprehensive solution for film pelletizing, offering state-of-the-art technology that ensures high-quality pellets with minimal waste. The system is designed to cater to a wide range of film materials, including LDPE, HDPE, LLDPE, and other types of plastic films. With its flexibility and versatility, the system can be easily integrated into existing production lines, making it a cost-effective and efficient solution for film pelletizing.One of the key features of the Film Pelletizing System is its ability to produce uniform and high-quality pellets. The system is equipped with advanced technology that ensures precise cutting and shaping of the pellets, resulting in consistent size and shape. This not only improves the quality of the pellets but also increases the efficiency of the production process.Moreover, the Film Pelletizing System is designed to minimize waste, making it a sustainable solution for film pelletizing. The system utilizes advanced technology to reduce the amount of trim and scrap generated during the pelletizing process, leading to a significant reduction in waste. This not only helps companies save on raw material costs but also contributes to a more sustainable and environmentally friendly production process.In addition to its quality and sustainability features, the Film Pelletizing System is also designed for ease of use and maintenance. The system is equipped with user-friendly controls and interfaces, making it easy for operators to monitor and adjust the production process. Furthermore, the system is designed for reliability and durability, requiring minimal maintenance and ensuring long-term performance.The introduction of the Film Pelletizing System is a testament to FPS's commitment to innovation and sustainability. The system is set to redefine the film pelletizing industry by offering a comprehensive solution that addresses the needs of manufacturers while minimizing environmental impact. With its high-quality pellets, reduced waste, and ease of use, the new system is poised to become a game-changer in the film pelletizing industry.The Film Pelletizing System has already garnered attention from industry experts and customers alike. With its innovative technology and sustainable features, the new system has been lauded for its potential to transform the film pelletizing industry. As the demand for sustainable and efficient production solutions continues to grow, FPS's new Film Pelletizing System is well-positioned to meet the needs of manufacturers and contribute to a more sustainable future.In conclusion, the introduction of the Film Pelletizing System represents a significant milestone for FPS and the film pelletizing industry. With its advanced technology, sustainability features, and ease of use, the new system is poised to revolutionize the way film pelletizing is done. As the industry continues to evolve, FPS remains committed to delivering innovative and sustainable solutions that meet the needs of its customers and contribute to a more sustainable future.

Affordable Recycling Machines: Get the Best Deals on Eco-Friendly Equipment

[Title]Recycling Machines Price Decrease to Foster Environmental Sustainability[Introduction]In an effort to promote environmental sustainability and reduce waste, numerous companies have been championing recycling initiatives and investing in innovative recycling machines. One prominent player in this domain has announced a significant price decrease for their recycling machines. This decision aims to make the technology more accessible and encourage wider adoption among businesses and communities globally. Let's delve into the details of this move and explore its potential impact on the recycling industry.[Body]The Environmental Equipment Company, a leader in recycling solutions, has made an important announcement aimed at accelerating the adoption of recycling machines worldwide. In a strategic move, the company has decided to decrease the price of their recycling machines by a substantial percentage. This decision is driven by their commitment to creating a more sustainable future by making recycling more economically viable and accessible.The new pricing structure will enable businesses and communities, regardless of their size and financial capabilities, to invest in recycling machines and contribute to a cleaner environment. This development is particularly crucial given the rising environmental concerns and the urgent need to address waste management issues. By reducing the financial barrier, the company hopes to encourage more organizations to get involved in recycling efforts and contribute to the circular economy.By deploying recycling machines in facilities such as manufacturing plants, shopping centers, and residential complexes, companies and individuals can substantially reduce the amount of waste that ends up in landfills. These machines have the capability to effectively sort, process, and recycle various materials, ranging from plastics and glass to paper and metal. This comprehensive approach is especially valuable as it promotes the utilization of resources, reduces energy consumption, and minimizes the ecological impact of waste disposal.Moreover, the price decrease of these recycling machines comes hand in hand with the company's commitment to constantly enhance the technology behind them. The Environmental Equipment Company invests heavily in research and development to ensure that their machines are state-of-the-art and highly efficient. By doing so, they strive to provide their customers with top-quality equipment that meets the ever-evolving demands of the recycling industry.This price reduction is also expected to generate a domino effect within the industry. Competing companies are likely to follow suit and adjust their prices accordingly, making recycling machines more affordable across the board. This healthy competition will ultimately benefit businesses and communities, creating a more cost-effective and sustainable environment.Looking ahead, the lower cost of recycling machines can potentially lead to a significant increase in recycling rates worldwide. By encouraging the deployment of these machines in various settings, the amount of waste that can be diverted from landfills will surge. This, in turn, will result in reduced greenhouse gas emissions, preservation of natural resources, and a substantial decrease in pollution levels. Achieving these objectives requires the collective efforts of individuals, businesses, and governments, and the decreased price of recycling machines plays a crucial role in achieving this shared vision.In conclusion, the recent price decrease of recycling machines by the Environmental Equipment Company represents a significant step forward in fostering environmental sustainability. By making their equipment more affordable, the company has paved the way for wider adoption of recycling machines across businesses and communities. The decreased price is expected to encourage other market players to follow suit, ultimately leading to a surge in recycling efforts worldwide. This development plays a pivotal role in combatting waste management issues, reducing pollution levels, and creating a more sustainable future for generations to come.

Twin Screw Extrusion Line Offers Advanced Technology for Manufacturing

High-Quality Lab Twin Screw Extrusion Line Launched by Leading Machinery Company[Company Name], a leading manufacturer of industrial machinery and equipment, has recently launched its latest innovation in the field of extrusion technology - the high-quality Lab Twin Screw Extrusion Line. This state-of-the-art extrusion line is designed to meet the ever-growing demand for precision and efficiency in the production of various plastic, rubber, and food products.The Lab Twin Screw Extrusion Line is a versatile and reliable solution that caters to the needs of research and development laboratories, small-scale production facilities, and educational institutions. With its compact design and superior performance, this extrusion line is ideal for producing small batches of materials for testing and experimentation purposes.The key features of the Lab Twin Screw Extrusion Line include:- High torque, co-rotating twin-screw extruder- Precise temperature and speed control- Modular configuration for flexibility and scalability- Easy operation and maintenanceThe extrusion line is capable of processing a wide range of materials, including thermoplastics, elastomers, and food ingredients, making it suitable for a variety of applications such as compounding, mixing, granulation, and extrusion.In addition to its advanced technical capabilities, the Lab Twin Screw Extrusion Line is designed with a focus on user-friendly operation and safety. The intuitive control system allows for easy adjustment of process parameters, while built-in safety features ensure reliable and trouble-free operation.As a leading supplier of extrusion machinery, [Company Name] is committed to delivering high-quality solutions that meet the specific needs of its customers. The Lab Twin Screw Extrusion Line is the result of extensive research and development efforts, aimed at providing a reliable and cost-effective solution for small-scale production and testing.With this latest addition to its product portfolio, [Company Name] strengthens its position as a trusted provider of advanced extrusion technology. The company's expertise in the design and manufacturing of extrusion equipment is backed by years of experience and a proven track record of delivering innovative solutions to the industry."We are excited to introduce the Lab Twin Screw Extrusion Line to the market," said a spokesperson for [Company Name]. "This extrusion line represents a significant advancement in our product offering, and we are confident that it will provide valuable benefits to our customers in terms of efficiency, performance, and flexibility."The launch of the Lab Twin Screw Extrusion Line underscores [Company Name]'s commitment to driving innovation and meeting the evolving needs of the extrusion industry. The company's dedication to quality, reliability, and customer satisfaction is exemplified in its latest offering, which is poised to set new standards for small-scale extrusion applications.As the demand for precision and versatility in extrusion processes continues to grow, the Lab Twin Screw Extrusion Line is well-positioned to meet the needs of research and development facilities, educational institutions, and small-scale production operations. With its superior performance, user-friendly design, and reliable operation, this extrusion line is set to make a significant impact in the industry.In conclusion, the launch of the high-quality Lab Twin Screw Extrusion Line by [Company Name] marks a significant milestone in the field of extrusion technology. With its advanced features and versatile capabilities, this extrusion line is set to provide valuable benefits to its users in terms of precision, efficiency, and reliability. As a leading supplier of extrusion machinery, [Company Name] continues to demonstrate its commitment to delivering innovative solutions that meet the evolving needs of the industry.

Efficient Pe Film Washing Machine for Recycling and Cleaning

The Pe Film Washing Machine represents the latest advancement in the field of plastic recycling technology. With its innovative design and cutting-edge features, this machine is set to revolutionize the process of plastic film washing and recycling.The Pe Film Washing Machine is manufactured by a renowned company in the recycling industry. This company has a long history of producing high-quality recycling equipment and machinery, and their products are trusted by businesses and organizations around the world. With a focus on innovation and excellence, the company is dedicated to developing solutions that address the growing challenges of plastic waste and environmental sustainability.The Pe Film Washing Machine is designed to efficiently and effectively wash and clean used plastic film, such as agricultural film, greenhouse film, packaging film, and more. With its advanced washing and drying processes, the machine can remove contaminants, such as dirt, debris, and labels, from the plastic film, resulting in a clean and high-quality end product. This clean plastic film can then be recycled and used in the production of new plastic products, reducing the need for virgin plastic and minimizing the environmental impact of plastic waste.One of the key features of the Pe Film Washing Machine is its high capacity and efficient operation. The machine is capable of processing large volumes of plastic film, making it suitable for businesses and facilities with high production demands. Its automatic operation and advanced control system also ensure that the washing process is consistent and optimized for maximum efficiency. This not only saves time and labor costs but also reduces the overall energy consumption of the recycling process.In addition to its impressive performance, the Pe Film Washing Machine is also designed with sustainability in mind. The machine is equipped with water recycling and filtration systems, allowing for the reuse of water throughout the washing process. This not only minimizes water consumption but also reduces the environmental impact of the recycling operation. Furthermore, the machine is built with high-quality and durable materials, ensuring its longevity and reliability for years to come.The company behind the Pe Film Washing Machine is committed to providing comprehensive support and service to its customers. From installation and training to maintenance and technical support, the company offers a range of services to ensure that the machine operates at its best at all times. This dedication to customer satisfaction and after-sales support sets the company apart as a trusted partner in the recycling industry.With the Pe Film Washing Machine, businesses and organizations have access to a state-of-the-art solution for plastic film recycling. By investing in this advanced machine, they can improve the efficiency of their recycling operations, reduce their environmental footprint, and contribute to a more sustainable future.In conclusion, the Pe Film Washing Machine, manufactured by this esteemed company, represents a significant advancement in plastic film recycling technology. With its innovative design, exceptional performance, and commitment to sustainability, this machine is poised to make a positive impact on the recycling industry. Businesses and organizations looking to enhance their recycling operations should consider the Pe Film Washing Machine as a valuable investment in their sustainability efforts.

Highly Efficient Pulverizer Machine for Plastic - A Complete Guide

Pulverizer Machine For Plastic - A Game Changer in Plastic RecyclingIn the wake of increasing concern over plastic pollution, the need for effective plastic recycling solutions has never been more urgent. In response to this global challenge, {Company Name} has taken a significant step forward with the introduction of their advanced Pulverizer Machine for plastic recycling.The {Company Name} is a leading manufacturer and supplier of industrial machinery and equipment, specializing in the development of innovative solutions for the recycling industry. With a strong commitment to sustainability and environmental responsibility, the company has positioned itself as a driving force in the quest for efficient and effective plastic recycling technologies.The Pulverizer Machine for plastic is a cutting-edge innovation that is set to revolutionize the way plastic waste is processed and recycled. Unlike traditional recycling methods that rely on mechanical shredding and grinding, this advanced machine utilizes a sophisticated pulverizing technique to break down plastic materials into fine particles. This not only allows for a more thorough and efficient recycling process but also produces a higher quality end product.One of the key features of the Pulverizer Machine is its versatility and adaptability. The machine is designed to handle a wide range of plastic materials, including PET, HDPE, PVC, and more. This flexibility makes it an ideal solution for recycling facilities and businesses that deal with various types of plastic waste.In addition to its exceptional performance, the Pulverizer Machine is also designed with user-friendly features that enhance its ease of operation and maintenance. This includes a user-friendly interface, automated controls, and a durable, low-maintenance design. As a result, operators can maximize productivity and efficiency while minimizing downtime and maintenance costs.The introduction of the Pulverizer Machine for plastic is a testament to {Company Name}'s ongoing commitment to innovation and sustainability. By providing the recycling industry with a state-of-the-art solution, the company is not only addressing the pressing issue of plastic waste but also empowering businesses and organizations to make a tangible impact on the environment.The benefits of the Pulverizer Machine extend beyond its environmental impact. By streamlining the plastic recycling process and producing high-quality recycled materials, the machine also offers significant economic advantages. Businesses and recycling facilities that implement this innovative technology can expect to see improvements in their operational efficiency, cost savings, and overall profitability.Furthermore, the Pulverizer Machine aligns with the growing global emphasis on circular economy principles, which prioritize the reduction, reuse, and recycling of materials. In doing so, {Company Name} is not only contributing to a more sustainable future but also positioning itself as a leader in the transition towards a more circular and resource-efficient economy.As the demand for effective plastic recycling solutions continues to rise, {Company Name} is poised to play a pivotal role in shaping the industry's future. With the Pulverizer Machine for plastic, the company has demonstrated its commitment to driving innovation, promoting sustainability, and empowering its customers to make a positive impact on the environment.In conclusion, the introduction of the Pulverizer Machine for plastic represents a significant milestone for {Company Name} and the plastic recycling industry as a whole. By leveraging cutting-edge technology and a strong sustainability focus, the company has pioneered a game-changing solution that is set to redefine the way plastic waste is processed and recycled. As the momentum for sustainable and responsible plastic recycling continues to grow, the Pulverizer Machine stands ready to lead the charge towards a more sustainable and circular future.

High-Quality PVC Profile Making Machine for Efficient Production

PVC Profile Making Machine Revolutionizing the Plastic IndustryIn recent years, the demand for PVC profiles has been on the rise due to their versatility and durability. With the increasing need for high-quality PVC profiles, the plastic industry has been seeking cutting-edge technologies to meet this demand. One company at the forefront of this technological advancement is {company name}, a leading manufacturer of PVC Profile Making Machines.{company name} has been in the business of manufacturing state-of-the-art PVC Profile Making Machines for over a decade. The company prides itself on its commitment to innovation and excellence, and their machines are known for their high efficiency, reliability, and precision. {company name} has earned a reputation for providing top-notch machinery that meets the evolving needs of the plastic industry.The latest addition to {company name}'s line of PVC Profile Making Machines is set to revolutionize the way PVC profiles are manufactured. This cutting-edge machine incorporates advanced technology and features that improve the speed and accuracy of the production process while ensuring the highest quality output.One of the key features of this new PVC Profile Making Machine is its automated controls, which are designed to streamline the manufacturing process and minimize human error. This not only increases efficiency but also reduces production costs, making it an attractive investment for plastic manufacturers.Additionally, the machine's precise molding capabilities enable the production of complex PVC profiles with intricate designs and tight tolerances. This level of precision is crucial for meeting the stringent quality standards of the industry and satisfying the demands of clients for high-quality PVC profiles.Furthermore, {company name} has integrated sustainability into the design of this new PVC Profile Making Machine. By incorporating energy-efficient components and optimizing the use of raw materials, the machine minimizes its environmental impact while maximizing its output.{company name} is dedicated to providing comprehensive support and training for their customers to ensure the seamless integration of their machines into existing production lines. Their team of technical experts offers professional guidance and assistance to help clients maximize the potential of their PVC Profile Making Machines.The launch of this new PVC Profile Making Machine underscores {company name}'s commitment to driving innovation in the plastic industry. It represents a significant milestone in the company's mission to deliver cutting-edge solutions that address the evolving needs of the market.In response to the unveiling of their latest machine, {company name} CEO stated, "We are proud to introduce this groundbreaking PVC Profile Making Machine, which embodies our dedication to excellence and innovation. Our goal is to empower plastic manufacturers with the tools they need to stay ahead in the industry and meet the growing demand for high-quality PVC profiles."The introduction of this new PVC Profile Making Machine is poised to make a significant impact on the plastic industry. With its advanced technology, precision molding capabilities, and sustainable design, it is set to redefine the standards for PVC profile manufacturing.As the demand for PVC profiles continues to grow, {company name} is poised to play a pivotal role in shaping the future of the plastic industry with its cutting-edge machinery. The company's unwavering commitment to innovation and excellence ensures that it will remain a driving force in the evolution of PVC profile manufacturing.

Efficient PVC Pipe Making Plant for High-Quality Production

PVC Pipe Making Plant Expands Production Capacity[Company Name], a leading manufacturer of PVC pipes and fittings, has announced plans to expand its production capacity with the establishment of a new PVC pipe making plant. The company, known for its innovative and high-quality products, aims to meet the increasing demand for PVC pipes in the construction and infrastructure sectors.The new plant, to be located in [City, Country], will utilize state-of-the-art machinery and technology to manufacture a wide range of PVC pipes, including pressure pipes, electrical conduits, and drainage pipes. With an initial investment of [amount] million, the plant is expected to have an annual production capacity of [capacity] metric tons of PVC pipes."We are excited to announce the establishment of our new PVC pipe making plant, which marks a significant milestone for our company," said [Spokesperson], CEO of [Company Name]. "This expansion reflects our commitment to meeting the growing needs of our customers and the market, and further solidifies our position as a leading player in the PVC pipe industry."The demand for PVC pipes has been steadily increasing in recent years, driven by the rapid urbanization and infrastructure development taking place in emerging economies. PVC pipes are widely used in various applications, including water distribution, sewerage, cable protection, and agricultural irrigation, due to their durability, corrosion resistance, and cost-effectiveness.[Company Name] has been at the forefront of the PVC pipe industry, offering a wide range of products that meet international quality standards. With a strong focus on research and development, the company has continuously innovated its manufacturing processes to enhance product performance and sustainability.The new PVC pipe making plant will enable [Company Name] to expand its product portfolio and offer a diverse range of PVC pipes to cater to the specific needs of different industries and applications. Additionally, the increased production capacity will allow the company to better serve its existing customers and explore new markets and business opportunities.In line with its commitment to sustainability, [Company Name] has incorporated environmentally friendly practices in the design and operation of the new plant. The utilization of energy-efficient equipment, waste minimization techniques, and responsible sourcing of raw materials will ensure that the plant operates in an eco-friendly manner.Furthermore, the new plant is expected to create job opportunities for the local community and contribute to the economic development of the region. By providing employment and supporting local suppliers and service providers, [Company Name] aims to have a positive impact on the social and economic fabric of the area.The establishment of the new PVC pipe making plant underscores [Company Name]'s dedication to staying ahead of industry trends and meeting the evolving needs of its customers. With a focus on innovation, quality, and sustainability, the company is poised to continue its upward trajectory in the PVC pipe market and make a significant contribution to the development of infrastructure worldwide.

Efficient PVC Pipe Belling Machine for Your Production Needs

PVC Pipe Belling Machine Revolutionizes Production ProcessThe PVC pipe industry has been revolutionized with the introduction of a new PVC pipe belling machine by an innovative machinery company. This state-of-the-art machine has the potential to streamline the production process and increase efficiency in the manufacturing of PVC pipes.The new PVC pipe belling machine is designed to automate the process of forming a bell-shaped end on PVC pipes, which is essential for joining pipes together. By automating this process, manufacturers can significantly reduce the time and labor required to produce belling pipes, leading to increased production capacity and lower production costs.The machine is equipped with advanced technologies that ensure precise and consistent belling of PVC pipes, resulting in high-quality products that meet industry standards. Its user-friendly interface allows for easy operation and customization of belling settings, making it suitable for a wide range of pipe sizes and belling requirements.In addition to its innovative features, the machine also boasts a compact and ergonomic design, making it suitable for integration into existing production lines without requiring extensive modifications. This means that manufacturers can easily incorporate the PVC pipe belling machine into their operations and start reaping the benefits of increased efficiency and productivity.Furthermore, the company behind this groundbreaking PVC pipe belling machine has a solid reputation for delivering high-quality machinery and equipment to the PVC pipe industry. With years of experience and expertise in the field, the company is dedicated to providing innovative solutions that meet the evolving needs of pipe manufacturers worldwide.As a leading manufacturer of machinery for the PVC pipe industry, the company is committed to excellence in product design, manufacturing, and customer support. The introduction of this new PVC pipe belling machine is a testament to the company’s dedication to advancing the industry through cutting-edge innovations and technologies.With its commitment to quality and innovation, the company has quickly gained a strong foothold in the PVC pipe industry, earning the trust and confidence of manufacturers around the world. Its products are known for their reliability, performance, and durability, making them a preferred choice for businesses seeking to enhance their production processes.In addition to the new PVC pipe belling machine, the company offers a comprehensive range of machinery and equipment for the PVC pipe industry, including extrusion lines, cutting machines, and other accessories. Its diverse product portfolio allows manufacturers to find all the equipment they need to set up and optimize their production lines for PVC pipe manufacturing.The company’s dedication to customer satisfaction is reflected in its commitment to providing comprehensive support and service to its clients. From initial consultation and installation to ongoing maintenance and technical support, the company aims to ensure that its customers have a seamless and efficient experience with its products.With the introduction of the new PVC pipe belling machine, the company is poised to further solidify its position as a leading provider of innovative machinery and equipment for the PVC pipe industry. Its commitment to excellence, coupled with its extensive industry experience, makes it a valuable partner for manufacturers looking to optimize their production processes and stay ahead in the competitive PVC pipe market.In conclusion, the new PVC pipe belling machine introduced by the company represents a significant advancement in the PVC pipe industry. Its innovative features, user-friendly design, and reliable performance make it an invaluable addition to any PVC pipe production line. As the industry continues to evolve, this new machine is set to play a key role in driving efficiency, productivity, and quality in PVC pipe manufacturing.

PVC Pipe Manufacturing Machine: An insight into the production process

PVC Pipe Manufacturing Machine Revolutionizes the IndustryThe global demand for PVC pipes is steadily increasing with the growth of construction activities, urbanization, and agricultural development. As a result, manufacturers are constantly seeking ways to increase their production capacity and efficiency. This quest for innovation has led to the development of the state-of-the-art PVC Pipe Manufacturing Machine, which is set to revolutionize the industry.The newly launched PVC Pipe Manufacturing Machine, developed by a prominent industry player (brand name removed), boasts cutting-edge technology and advanced features. This machine has been designed to streamline the entire production process, from raw material handling to the final product. It promises to significantly reduce the labor-intensive tasks associated with traditional manufacturing methods, resulting in increased productivity and cost-effectiveness for manufacturers.One of the key features of this PVC Pipe Manufacturing Machine is its automated operation. Equipped with modern control systems, it can perform complex tasks with minimal human intervention. This not only eliminates errors and inconsistencies but also enhances overall production efficiency. The machine ensures accurate and precise pipe dimensions, allowing manufacturers to deliver high-quality products consistently.Efficiency is further enhanced by the machine's capability to handle a wide range of pipe sizes. With customizable settings, manufacturers can produce pipes of various diameters and lengths as per their specific requirements. This flexibility enables them to cater to a broader market, providing a competitive edge in the industry.The advanced technology integrated into the PVC Pipe Manufacturing Machine also ensures energy optimization. With energy costs being a significant concern for manufacturers, this machine comes as a breath of fresh air. It minimizes power consumption by utilizing energy-efficient motors and advanced heating and cooling systems. This not only reduces operating costs but also contributes to sustainability efforts by lowering the carbon footprint of manufacturing processes.Moreover, the machine's user-friendly interface offers ease of operation and monitoring for operators. The control panel displays real-time data on production speed, error detection, and maintenance requirements, allowing operators to make informed decisions promptly. The automated quality control system constantly monitors the production process, identifying and rectifying any faults in real-time. This results in improved product consistency and reduced waste.Additionally, the PVC Pipe Manufacturing Machine's durability and reliability ensure long-term productivity. Constructed with high-quality materials and components, it can withstand the demands of continuous operation. This significantly reduces machine downtime and maintenance costs, translating into enhanced profitability for manufacturers.As a market leader in the manufacturing industry, the company behind this revolutionary machine is committed to providing exceptional customer support. They offer comprehensive training for machine operators to ensure efficient utilization and maximize its potential. Additionally, their after-sales service includes prompt technical assistance, spare parts availability, and regular maintenance. This commitment to customer satisfaction sets them apart from their competitors.Overall, the introduction of the PVC Pipe Manufacturing Machine marks a significant breakthrough in the industry. Its advanced features, energy efficiency, flexibility, and reliability are set to redefine the manufacturing process for PVC pipes. With its ability to meet the growing demands of the market, this innovative machine will undoubtedly revolutionize the global PVC pipe industry and drive greater growth and success for manufacturers worldwide.