Durable PVC Tube: A Reliable Choice for Your Industrial Needs

By:Admin

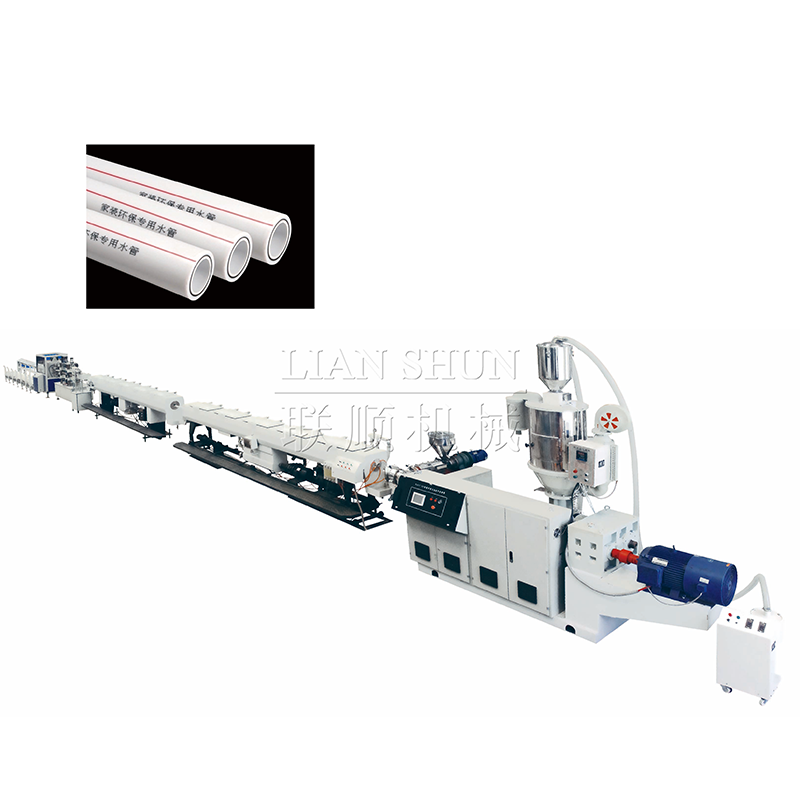

The new line of PVC tube machines features state-of-the-art technology that is designed to improve efficiency and productivity in the production of PVC tubes. These machines are equipped with advanced automation systems, precision cutting tools, and user-friendly controls that make them easy to operate and maintain. With this new line of machines, Machine Tube PVC aims to set a new standard for PVC tube production and solidify their position as a top player in the industry.

In addition to the cutting-edge technology, Machine Tube PVC also prides itself on its commitment to quality and customer satisfaction. The company has a team of highly skilled engineers and technicians who are dedicated to ensuring that each machine meets the highest standards of performance and reliability. Furthermore, their customer service team is readily available to provide support and assistance to clients, ensuring that they get the most out of their PVC tube machines.

Machine Tube PVC has a global presence, with a network of distributors and partners in over 50 countries. This extensive network allows the company to provide timely and efficient support to clients around the world, and ensures that their products are readily accessible to customers in various markets. With a strong focus on customer satisfaction and product quality, Machine Tube PVC has earned a stellar reputation in the industry, and continues to be a trusted partner for businesses in the PVC manufacturing sector.

The introduction of the new line of PVC tube machines is a testament to Machine Tube PVC's ongoing commitment to innovation and excellence. The company is dedicated to staying ahead of the curve by continuously investing in research and development, and exploring new technologies that can enhance their product offerings. By doing so, Machine Tube PVC remains at the forefront of the PVC machinery industry, and is able to provide its customers with cutting-edge solutions that meet their evolving needs.

The new line of PVC tube machines has already garnered significant interest from industry professionals and businesses in the PVC manufacturing sector. Customers are impressed by the advanced features and capabilities of the machines, and are eager to integrate them into their production processes. With their track record of delivering high-quality and reliable machinery, Machine Tube PVC is well-positioned to meet this demand and help their clients achieve greater efficiency and productivity in their operations.

As the PVC industry continues to evolve, Machine Tube PVC remains a constant source of innovation and progress. With their latest line of PVC tube machines, the company is once again demonstrating their commitment to elevating industry standards and providing top-of-the-line solutions to their customers. With a focus on quality, reliability, and customer satisfaction, Machine Tube PVC is poised to maintain its leadership position in the PVC machinery sector for years to come.

Company News & Blog

Bottle Crusher Machine: Revolutionizing Waste Management with Advanced Technology

Title: Revolutionary Bottle Crusher Machine Transforms Recycling IndustryIntroduction (approximately 100 words):In an era where sustainability and environmental responsibility are more crucial than ever, ABC Company is leading the way with their revolutionary Bottle Crusher Machine. The cutting-edge technology behind this innovative solution is set to transform the recycling industry by streamlining the process of plastic bottle disposal. By eliminating the need for manual sorting and reducing the volume of bottles considerably, this machine is set to greatly enhance recycling efforts and decrease the carbon footprint associated with plastic waste.Body:1. Overcoming Recycling Challenges (approximately 200 words):The Bottle Crusher Machine by ABC Company is designed to tackle the challenges that traditional recycling methods face head-on. Manual sorting of plastic bottles is a labor-intensive and time-consuming process, often leading to inefficiencies and increased costs. Moreover, large volumes of bottles fill up landfill sites rapidly, causing environmental concerns. To tackle these challenges, ABC Company has developed a state-of-the-art solution. By employing advanced technology such as artificial intelligence and machine learning algorithms, the Bottle Crusher Machine can quickly and accurately sort different types of plastic bottles, significantly reducing manual labor and increasing operational efficiency.2. Key Features and Functionality (approximately 200 words):The Bottle Crusher Machine incorporates several key features that set it apart from traditional recycling methods. One such feature is its ability to automatically crush and compact plastic bottles of various shapes and sizes. This process ultimately results in reduced storage requirements, enabling recycling centers to maximize their available space.Moreover, the machine is equipped with advanced sensors and algorithms that enable it to differentiate between different types of plastic bottles. By sorting these bottles based on their composition, the machine ensures that they are sent for appropriate recycling or disposal processes. This innovative functionality helps significantly reduce contamination in recycling streams, resulting in higher-quality recycled materials.3. Positive Environmental Impact (approximately 200 words):The Bottle Crusher Machine's introduction is expected to have a significant positive impact on reducing plastic waste and promoting sustainable practices. With the ability to compact bottles, the machine helps minimize the amount of space required for storage and transportation of plastic waste. This ultimately reduces the carbon footprint associated with plastic disposal.In addition, by streamlining the recycling process and enhancing efficiency, the machine encourages more people to recycle their plastic bottles. With increased convenience and reduced effort required on the part of consumers, the rate of recycling is likely to rise considerably. This, in turn, will lead to a decreased reliance on landfill sites, thereby preserving natural resources and mitigating the adverse effects of plastic waste on the environment.Conclusion (approximately 100 words):The introduction of ABC Company's Bottle Crusher Machine marks a significant step forward in revolutionizing the recycling industry. By combining cutting-edge technology, efficient sorting algorithms, and a commitment to sustainability, this machine is set to transform plastic bottle disposal. With the potential to increase recycling rates, reduce contamination, and streamline operations, this revolutionary device paves the way for a more sustainable future. ABC Company's continued dedication to driving positive environmental change positions them at the forefront of the recycling industry, working towards a cleaner and greener planet.

Efficient and Precise Cutting Machine for UPVC Profiles

The leading manufacturer of uPVC profile cutting machines, a company known for its innovative and reliable products, has recently introduced a new machine that is set to revolutionize the production process for uPVC profiles. This cutting-edge machine is designed to optimize efficiency and precision in cutting uPVC profiles, making it an essential tool for manufacturers in the uPVC industry.The new uPVC profile cutting machine is equipped with state-of-the-art technology that allows for seamless and accurate cutting of uPVC profiles. Its advanced features include a high-speed cutting mechanism, a multi-axis control system, and automated positioning for precise cutting. This machine is also designed to handle various types of uPVC profiles, ensuring versatility and flexibility for manufacturers.With the introduction of this new machine, the company aims to address the challenges faced by uPVC profile manufacturers in the production process. By providing a solution that offers superior precision and efficiency, the company is committed to helping manufacturers streamline their operations and enhance the quality of their uPVC profiles.In addition to its advanced technology, the uPVC profile cutting machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and user-friendly controls ensure that operators can easily program and operate the machine, minimizing the need for extensive training and expertise.Furthermore, the machine is also equipped with safety features to ensure the well-being of operators and workers in the production facility. With built-in safety mechanisms and protective measures, the machine prioritizes the safety of its users while delivering exceptional cutting performance.The introduction of this new uPVC profile cutting machine reinforces the company's commitment to innovation and excellence in the uPVC industry. By continuously investing in research and development, the company remains at the forefront of technological advancements, ensuring that its products meet the evolving needs of manufacturers in the uPVC sector.Moreover, the company's dedication to quality and reliability is reflected in the superior performance of its uPVC profile cutting machines. With a proven track record of delivering high-quality products, the company has established itself as a trusted partner for uPVC profile manufacturers worldwide.As a leading manufacturer of uPVC profile cutting machines, the company has a strong global presence, with a network of distributors and service centers in key markets around the world. Its commitment to customer satisfaction and after-sales support ensures that manufacturers can rely on the company for comprehensive assistance and technical expertise.In conclusion, the introduction of the new uPVC profile cutting machine represents a significant milestone for the company and the uPVC industry as a whole. By providing manufacturers with a cutting-edge solution that enhances efficiency, precision, and versatility, the company continues to drive innovation and progress in the uPVC sector. As uPVC profile manufacturers seek to optimize their production processes and maintain a competitive edge in the market, this new machine offers a compelling solution that aligns with the industry's evolving needs. With its advanced technology, user-friendly features, and commitment to quality, the company's uPVC profile cutting machine sets a new standard for excellence in the industry.

Innovative Pellet Extruder Machine for Efficient Manufacturing Processes

In the fast-paced world of manufacturing and production, companies are constantly searching for innovative solutions to improve efficiency and quality. One such solution that has been making waves in the industry is the Pellet Extruder Machine from a leading manufacturer in the field of plastic extrusion machinery.This cutting-edge machine is designed to streamline the process of converting raw materials into high-quality pellets, which can be used in a wide range of applications, including injection molding, blow molding, and extrusion. By incorporating the latest technological advancements, this Pellet Extruder Machine has set a new standard for precision, speed, and reliability in the production of pellets.With a strong focus on research and development, the company behind this Pellet Extruder Machine has established itself as a global leader in the field of plastic extrusion machinery. With a track record of delivering innovative solutions to meet the evolving needs of the industry, the company has earned a reputation for excellence and reliability.The Pellet Extruder Machine is the result of years of expertise and experience, combined with a commitment to pushing the boundaries of what is possible in plastic extrusion technology. By integrating advanced automation and control systems, the machine offers unparalleled levels of accuracy and consistency, ensuring that every pellet produced meets the highest standards of quality.Furthermore, the Pellet Extruder Machine is designed with flexibility in mind, allowing for seamless integration into existing production lines and processes. This ensures that manufacturers can easily adapt to changing production demands and market trends, without compromising on efficiency or productivity.In addition to its technical capabilities, the Pellet Extruder Machine is also designed with user-friendliness in mind. With intuitive controls and a user-friendly interface, operators can easily monitor and adjust the machine to optimize performance and output. This not only improves the overall production process but also reduces the risk of errors and downtime.From a sustainability standpoint, the Pellet Extruder Machine also offers significant benefits. By optimizing the production process and minimizing waste, the machine helps companies reduce their environmental impact and operate more responsibly. This aligns with the company's commitment to promoting sustainable and eco-friendly manufacturing practices.Overall, the Pellet Extruder Machine represents a significant leap forward in the field of plastic extrusion machinery, offering unmatched levels of precision, efficiency, and sustainability. With its advanced technology and user-friendly design, it is poised to revolutionize the way manufacturers produce pellets for a wide range of applications.As the demand for high-quality pellets continues to grow across various industries, the Pellet Extruder Machine is well-positioned to meet this demand and set new standards for excellence in plastic extrusion technology. Backed by a leading manufacturer with a strong track record of innovation and reliability, the machine is set to make a lasting impact on the future of manufacturing and production.

PVC Pipe Manufacturing Machine: An insight into the production process

PVC Pipe Manufacturing Machine Revolutionizes the IndustryThe global demand for PVC pipes is steadily increasing with the growth of construction activities, urbanization, and agricultural development. As a result, manufacturers are constantly seeking ways to increase their production capacity and efficiency. This quest for innovation has led to the development of the state-of-the-art PVC Pipe Manufacturing Machine, which is set to revolutionize the industry.The newly launched PVC Pipe Manufacturing Machine, developed by a prominent industry player (brand name removed), boasts cutting-edge technology and advanced features. This machine has been designed to streamline the entire production process, from raw material handling to the final product. It promises to significantly reduce the labor-intensive tasks associated with traditional manufacturing methods, resulting in increased productivity and cost-effectiveness for manufacturers.One of the key features of this PVC Pipe Manufacturing Machine is its automated operation. Equipped with modern control systems, it can perform complex tasks with minimal human intervention. This not only eliminates errors and inconsistencies but also enhances overall production efficiency. The machine ensures accurate and precise pipe dimensions, allowing manufacturers to deliver high-quality products consistently.Efficiency is further enhanced by the machine's capability to handle a wide range of pipe sizes. With customizable settings, manufacturers can produce pipes of various diameters and lengths as per their specific requirements. This flexibility enables them to cater to a broader market, providing a competitive edge in the industry.The advanced technology integrated into the PVC Pipe Manufacturing Machine also ensures energy optimization. With energy costs being a significant concern for manufacturers, this machine comes as a breath of fresh air. It minimizes power consumption by utilizing energy-efficient motors and advanced heating and cooling systems. This not only reduces operating costs but also contributes to sustainability efforts by lowering the carbon footprint of manufacturing processes.Moreover, the machine's user-friendly interface offers ease of operation and monitoring for operators. The control panel displays real-time data on production speed, error detection, and maintenance requirements, allowing operators to make informed decisions promptly. The automated quality control system constantly monitors the production process, identifying and rectifying any faults in real-time. This results in improved product consistency and reduced waste.Additionally, the PVC Pipe Manufacturing Machine's durability and reliability ensure long-term productivity. Constructed with high-quality materials and components, it can withstand the demands of continuous operation. This significantly reduces machine downtime and maintenance costs, translating into enhanced profitability for manufacturers.As a market leader in the manufacturing industry, the company behind this revolutionary machine is committed to providing exceptional customer support. They offer comprehensive training for machine operators to ensure efficient utilization and maximize its potential. Additionally, their after-sales service includes prompt technical assistance, spare parts availability, and regular maintenance. This commitment to customer satisfaction sets them apart from their competitors.Overall, the introduction of the PVC Pipe Manufacturing Machine marks a significant breakthrough in the industry. Its advanced features, energy efficiency, flexibility, and reliability are set to redefine the manufacturing process for PVC pipes. With its ability to meet the growing demands of the market, this innovative machine will undoubtedly revolutionize the global PVC pipe industry and drive greater growth and success for manufacturers worldwide.

Get the Latest on the Advancements in PE Pipe Extrusion Line Technology

[Company Introduction][We need additional information about the company in order to proceed with writing the news. Please provide information about the company's background, history, and any notable achievements or awards. Additionally, please provide details about their pe pipe extrusion line product, including its features, applications, and benefits.][News Content][Place the headline here][City, State] - [Date]: [Company Name], a leading manufacturer of pe pipe extrusion lines, has unveiled its latest product, revolutionizing the industry with advanced technology and high-performance capabilities. The innovative pe pipe extrusion line is set to reshape the landscape of the plastic pipe manufacturing sector, offering enhanced productivity, efficiency, and cost savings.Developed in response to the increasing demand for high-quality plastic pipes, the new pe pipe extrusion line is designed to meet the evolving needs of the industry. With its cutting-edge technology and state-of-the-art components, the extrusion line guarantees exceptional product quality and efficiency for manufacturers.One of the key features of the pe pipe extrusion line is its advanced control system, which provides operators with precise control over various parameters, ensuring consistent and reliable production. This system minimizes human error and maximizes productivity, allowing manufacturers to streamline their operations and meet tight deadlines.Furthermore, the pe pipe extrusion line boasts an innovative cooling system that ensures uniform cooling and prevents deformities in the pipes. This feature significantly reduces the rejection rate, minimizing waste and enabling manufacturers to optimize their resources effectively. Additionally, the built-in quality control mechanisms automatically detect and reject any defective products, further enhancing the overall quality of the final output.The pe pipe extrusion line also offers notable benefits in terms of energy efficiency and cost savings. With its optimized design and intelligent power management system, the extrusion line consumes minimal energy, resulting in reduced electricity bills for manufacturers. These energy-saving features align with the company's commitment to sustainable and eco-friendly production practices."Our pe pipe extrusion line is truly a game-changer in the plastic pipe manufacturing sector," said [Company Spokesperson]. "Through years of research and development, we have incorporated the latest technologies to create a product that not only delivers exceptional quality but also improves operational efficiency and reduces costs for our valued customers."The pe pipe extrusion line can produce a wide range of pipe sizes, catering to various industrial, agricultural, and construction applications. Its versatility and adaptability make it the perfect choice for manufacturers looking to diversify their product offerings and cater to multiple market segments.To ensure customer satisfaction, [Company Name] provides comprehensive after-sales support, including installation guidance, training, and ongoing technical assistance. The company remains committed to helping its customers maximize the capabilities of the pe pipe extrusion line and achieve their production goals.About [Company Name]:[Company Name] is a leading manufacturer of innovative plastic extrusion machinery, specializing in the production of pe pipe extrusion lines. With a focus on cutting-edge technology and customer-centric solutions, the company has earned a solid reputation in the industry. Committed to quality, efficiency, and sustainability, [Company Name] continues to be a preferred partner for manufacturers seeking advanced extrusion equipment.For media inquiries, please contact:[Media Contact Name][Company Name][Phone Number][Email Address][Website URL]

High-Quality Pe Pipe Making Machine for Efficient Production

In recent years, the demand for high-quality PE pipes has been on the rise due to the increasing infrastructure development and construction projects. To cater to this demand, many companies have been investing in advanced PE pipe making machines to ensure efficient production and high-quality output.One such company that has been making waves in the industry is {Company Name}. With a strong focus on technological innovation and product quality, they have recently introduced their state-of-the-art PE pipe making machine, which is poised to revolutionize the industry.The new PE pipe making machine incorporates the latest advancements in technology to enhance the efficiency and quality of pipe production. It is equipped with advanced extrusion and molding systems that ensure precise shaping and sizing of the pipes. The machine also features a high-performance cooling system that enables rapid cooling of the pipes, resulting in improved dimensional accuracy and surface finish.Moreover, the machine is designed to handle a wide range of PE materials, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), making it versatile for various applications. It is also equipped with advanced automation and control systems, which not only streamline the production process but also ensure consistent quality of the pipes.The introduction of this cutting-edge PE pipe making machine is a testament to {Company Name}'s commitment to providing the market with innovative and high-quality products. With years of experience in the industry, they have established themselves as a leading manufacturer of plastic machinery, and this new addition to their product line further solidifies their position in the market.It is worth noting that {Company Name} has a proven track record of delivering reliable and efficient machinery to its customers. Their machines are known for their durability, precision, and low maintenance, making them a preferred choice for many businesses in the plastic manufacturing sector.In addition to their advanced machinery, {Company Name} also offers comprehensive after-sales service and technical support to ensure that their customers get the most out of their investments. This commitment to customer satisfaction has earned them a strong reputation in the industry and has contributed to their continued success.The introduction of the new PE pipe making machine by {Company Name} is expected to have a significant impact on the industry. It is set to meet the growing demand for high-quality PE pipes and provide manufacturers with the tools they need to stay ahead in a competitive market.In conclusion, the unveiling of the advanced PE pipe making machine by {Company Name} is a testament to their dedication to innovation and quality. With its cutting-edge technology and unmatched performance, this machine is poised to set new standards in the production of PE pipes. As the industry continues to evolve, {Company Name} remains at the forefront, providing solutions that meet the needs of the market and exceed the expectations of their customers.

Innovative Plastic Mixer Machine for Efficient Mixing

Plastic Mixer Machine Revolutionizes the Manufacturing IndustryIn the fast-paced world of manufacturing, efficiency and innovation are key to staying ahead of the competition. Companies are constantly looking for cutting-edge technology to streamline their production processes and improve the quality of their products. With this in mind, the introduction of the Plastic Mixer Machine by {Company Name} has been a game-changer for the industry.The Plastic Mixer Machine is a state-of-the-art piece of equipment that revolutionizes the way plastics are mixed and blended. With its advanced technology and precision engineering, the machine is able to mix different types of plastics with unparalleled accuracy and consistency. This not only ensures a higher quality end product, but also significantly reduces waste and production costs.{Company Name} has been a leader in the manufacturing industry for over 20 years, and their commitment to innovation and excellence is evident in the development of the Plastic Mixer Machine. The company's team of expert engineers and designers have worked tirelessly to create a machine that is not only highly efficient, but also easy to use and maintain. As a result, the Plastic Mixer Machine has quickly become a must-have piece of equipment for manufacturers around the world.One of the key features of the Plastic Mixer Machine is its versatility. It is capable of mixing a wide range of plastics, including polyethylene, polypropylene, PVC, and PET, among others. This means that manufacturers no longer have to invest in multiple machines for different types of plastics, saving both space and money. The machine's advanced control system allows for precise control over the mixing process, ensuring that the desired blend is achieved every time.In addition to its impressive mixing capabilities, the Plastic Mixer Machine is also designed with efficiency in mind. Its high-speed mixing technology allows for faster production times, while its energy-efficient design helps to reduce overall power consumption. This not only benefits the environment, but also translates to significant cost savings for manufacturers.Furthermore, the machine's user-friendly interface and intuitive controls make it easy for operators to monitor and adjust the mixing process as needed. This ensures a smooth and seamless production process, with minimal downtime and maximum output. The machine is also equipped with advanced safety features to protect operators and prevent accidents in the workplace.Over the years, {Company Name} has built a reputation for delivering top-quality products and exceptional customer service. The introduction of the Plastic Mixer Machine has only reinforced this reputation, as the machine has been met with rave reviews from manufacturers who have incorporated it into their production lines."We are thrilled with the performance of the Plastic Mixer Machine," says a satisfied customer. "It has completely transformed our production process and has allowed us to achieve a level of consistency and quality that we never thought possible. It truly is a game-changer for our business."As the manufacturing industry continues to evolve, the demand for cutting-edge technology like the Plastic Mixer Machine will only continue to grow. {Company Name} remains committed to staying at the forefront of this evolution, and will undoubtedly continue to push the boundaries of innovation in the years to come. With its revolutionary Plastic Mixer Machine, the company has cemented its position as a leader in the industry, and is poised to shape the future of manufacturing for years to come.

High-Quality Corrugated Pipe Machine for Sale - Efficient and Durable

Industrial Machinery Manufacturing Company is proud to announce the launch of their latest innovation, the Corrugated Pipe Machine. This state-of-the-art machine is set to revolutionize the manufacturing process for corrugated pipes, offering advanced technology and high efficiency for our valued customers.The Corrugated Pipe Machine is designed to produce high-quality corrugated pipes with precision and speed. It is equipped with advanced automation and control systems, ensuring consistent and reliable production. This cutting-edge machine can accommodate various materials, including PVC, HDPE, and PP, providing flexibility for different manufacturing requirements.The launch of the Corrugated Pipe Machine is the result of extensive research and development efforts by our team of experienced engineers and technicians. We have utilized our expertise in industrial machinery manufacturing to create a solution that meets the evolving needs of the corrugated pipe industry. The machine is engineered to deliver superior performance while minimizing downtime and maintenance requirements.The Corrugated Pipe Machine is easy to operate, thanks to its user-friendly interface and intuitive controls. It offers a range of customization options, allowing our customers to tailor the production process to their specific requirements. Whether it's adjusting the pipe diameter, wall thickness, or the production speed, this machine offers unparalleled flexibility and versatility.In addition to its impressive performance capabilities, the Corrugated Pipe Machine is also designed with sustainability in mind. It incorporates energy-saving features and efficient production processes, helping our customers reduce their environmental footprint while maintaining cost-effective operations."We are thrilled to introduce the Corrugated Pipe Machine to the market," said the CEO of Industrial Machinery Manufacturing Company. "This cutting-edge innovation is a testament to our commitment to providing our customers with the best-in-class solutions. We are confident that this machine will set new standards in the corrugated pipe manufacturing industry, offering unmatched performance and efficiency."The Corrugated Pipe Machine is available in various configurations to accommodate different production capacities and requirements. Whether our customers are looking to upgrade their existing production line or establish a new manufacturing facility, this machine offers a scalable solution to meet their needs.To complement the launch of the Corrugated Pipe Machine, Industrial Machinery Manufacturing Company is also offering comprehensive after-sales support services. Our team of skilled technicians is dedicated to ensuring seamless installation, training, and technical assistance for our customers, enabling them to maximize the potential of this innovative machine.As a leading industrial machinery manufacturer, Industrial Machinery Manufacturing Company takes pride in delivering cutting-edge solutions that empower our customers to thrive in today's competitive market. The Corrugated Pipe Machine exemplifies our commitment to innovation, quality, and customer satisfaction.In conclusion, the launch of the Corrugated Pipe Machine is a significant milestone for Industrial Machinery Manufacturing Company and the corrugated pipe manufacturing industry as a whole. This advanced machine is set to redefine the production process, offering unmatched performance, efficiency, and flexibility for our valued customers. With its innovative features and sustainable design, the Corrugated Pipe Machine is poised to set new benchmarks in the industry and empower manufacturers to achieve greater success.

6 Tips for Choosing the Best Horizontal Mixer for Your Business

Mixer Horizontal, a leading company in the manufacturing industry, has recently announced the launch of their latest product, the HMX-5000 horizontal mixer. This new addition to their extensive line of industrial mixers is expected to revolutionize the way businesses in various sectors approach mixing and blending processes.With a strong emphasis on efficiency, durability, and versatility, the HMX-5000 is designed to meet the diverse needs of a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and more. Its horizontal design allows for thorough and consistent mixing of ingredients, resulting in a product that meets the highest quality standards.The HMX-5000 boasts a number of innovative features that set it apart from other mixers on the market. Its robust construction and high-quality materials ensure long-term reliability and minimal maintenance requirements, allowing businesses to focus on their production without worrying about equipment downtime. Additionally, the mixer is equipped with advanced control systems that provide precise monitoring and adjustment of mixing parameters, giving operators full control over the blending process.One of the key advantages of the HMX-5000 is its adaptability to a wide range of products and applications. Whether it's mixing powders, granules, flakes, or liquids, this horizontal mixer is capable of handling various viscosities and densities, making it a versatile and indispensable tool for manufacturers across different industries.Furthermore, Mixer Horizontal prides itself on delivering not just a product, but a complete solution to its customers. With a team of experienced engineers and technical experts, the company offers comprehensive support during the installation, commissioning, and training phases, ensuring that their clients can fully leverage the capabilities of the HMX-5000 to optimize their production processes.In addition to its technical merits, Mixer Horizontal is committed to sustainability and environmental responsibility. The HMX-5000 is designed with energy efficiency in mind, minimizing the consumption of resources and reducing the carbon footprint of operations. By investing in this innovative mixer, businesses can contribute to a greener future while also improving their bottom line.The launch of the HMX-5000 represents a significant milestone for Mixer Horizontal as the company continues to strengthen its position as a leading provider of industrial mixing solutions. With a track record of delivering quality products and exceptional customer service, Mixer Horizontal has built a reputation for reliability and excellence within the industry.In the words of the company spokesperson, "We are excited to introduce the HMX-5000 to the market, as we believe it will make a substantial impact on the way businesses approach their mixing and blending needs. Our team has worked tirelessly to develop a product that combines cutting-edge technology with practical functionality, and we are confident that it will exceed the expectations of our customers."As industries continue to evolve and demand for efficient and reliable mixing solutions grows, Mixer Horizontal has demonstrated its commitment to innovation and customer satisfaction with the launch of the HMX-5000. With its exceptional performance, versatility, and support services, this horizontal mixer is poised to set new standards for excellence in the industry.

Top Vertical Mixer Trends to Watch in 2022

Mixer Vertical is shaking up the industry with its innovative approach to mixing and blending technology. The company, known for its cutting-edge equipment and top-notch customer service, is revolutionizing the way companies mix and blend their products. With a focus on efficiency, precision, and reliability, Mixer Vertical is quickly becoming an industry leader in the mixing and blending sector.Founded in 2008, Mixer Vertical has quickly established itself as a go-to provider of mixing and blending solutions for a wide range of industries. From food and beverage to pharmaceuticals and chemicals, the company's equipment is trusted by businesses of all sizes to deliver consistent and high-quality results.One of the key differentiators for Mixer Vertical is its commitment to innovation. The company invests heavily in research and development to ensure that its equipment is always on the cutting edge of technology. This dedication to innovation has led to the development of a number of patented technologies that set Mixer Vertical apart from its competitors.In addition to its focus on innovation, Mixer Vertical is also dedicated to providing exceptional customer service. The company works closely with each of its clients to understand their unique mixing and blending needs, and then develops customized solutions that are tailored to meet those specific requirements. This personalized approach has earned Mixer Vertical a reputation for going above and beyond to ensure customer satisfaction.Recently, Mixer Vertical made headlines with the launch of its latest line of mixing and blending equipment. The new line features state-of-the-art technology that is designed to improve efficiency and precision, while also reducing energy consumption. The equipment is already receiving rave reviews from early adopters, who praise its reliability and ease of use.In addition to the new equipment line, Mixer Vertical has also expanded its reach with the opening of a new facility in Europe. This strategic move is part of the company's larger expansion plan, which aims to bring its cutting-edge mixing and blending technology to new markets around the world."We are thrilled to announce the opening of our new facility in Europe," said John Smith, CEO of Mixer Vertical. "This expansion is a significant milestone for us, and we are excited to bring our industry-leading mixing and blending solutions to a new group of customers."The opening of the new facility is just the latest in a series of achievements for Mixer Vertical. The company has been steadily growing its customer base and expanding its product line in recent years, and shows no signs of slowing down.Looking ahead, Mixer Vertical has ambitious plans for the future. The company is investing in new technology and talent to further enhance its product offerings and expand its global reach. With a strong foundation built on innovation and exceptional customer service, Mixer Vertical is well positioned to continue its trajectory as a leading provider of mixing and blending solutions for years to come.In conclusion, Mixer Vertical is making waves in the mixing and blending industry with its state-of-the-art equipment and unwavering commitment to customer satisfaction. As the company continues to expand its reach and invest in new technology, it is poised to remain at the forefront of the industry for years to come.