Efficient Friction Washer for Plastic Recycling: A Game Changer for Waste Management

By:Admin

The Friction Washer, developed by [], is designed to tackle the increasing challenges of plastic recycling. With the global demand for recycled plastics on the rise, there is a pressing need for more advanced and efficient recycling technologies. The Friction Washer addresses this need by offering a cutting-edge solution that is capable of processing a wide range of plastic materials, including PET, HDPE, and PP, among others.

This innovative machine utilizes a unique frictional washing process to effectively clean and separate plastic materials. By using a combination of friction, water, and detergent, the Friction Washer is able to remove contaminants, such as dirt, labels, and adhesives, from the plastic waste. This thorough cleaning process ensures that the recycled plastic meets the highest quality standards, making it suitable for a wide range of end-use applications.

One of the key advantages of the Friction Washer is its ability to handle a variety of plastic materials, including heavily soiled and contaminated plastics. This versatility makes it an ideal solution for recycling facilities that process a diverse range of plastic waste streams. In addition, the Friction Washer is designed to operate with minimal water and energy consumption, making it a more sustainable and cost-effective option for plastic recycling operations.

In the words of [], "The Friction Washer represents a significant advancement in plastic washing technology. Our goal is to provide recycling facilities with a reliable and efficient solution for processing plastic waste, ultimately contributing to a more sustainable and circular economy."

The Friction Washer is set to have a major impact on the plastic recycling industry, offering a more efficient and sustainable solution for processing plastic waste. With its advanced washing technology and versatile capabilities, this innovative machine is poised to revolutionize the way plastics are recycled, making the process more efficient and environmentally friendly than ever before.

In addition to the Friction Washer, [] offers a comprehensive range of equipment and solutions for the plastic recycling industry. With a strong focus on innovation and sustainability, the company is committed to providing cutting-edge technologies that help recycling facilities maximize their operational efficiency and minimize their environmental impact.

As the demand for recycled plastics continues to grow, solutions like the Friction Washer are critical for meeting this demand in a sustainable manner. By investing in advanced recycling technologies, businesses and communities can work together to create a more circular economy, where plastic waste is repurposed and reused instead of ending up in landfills or polluting the environment.

With the introduction of the Friction Washer, [] is leading the way in advancing the plastic recycling industry, offering a game-changing solution that sets new standards for efficiency, sustainability, and quality in plastic washing technology. This innovative machine represents a significant step forward in the journey towards a more sustainable and circular economy, where plastic waste is recycled and repurposed to create a cleaner and healthier planet for future generations.

Company News & Blog

Effective Ways to Recycle Soft Plastics

[Company Logo]Soft Plastic Recycling: A Step Towards Sustainable Future In today's fast-paced and consumer-driven world, the importance of recycling and sustainability cannot be overstated. As the global concern for environmental issues continues to grow, companies are striving to find innovative solutions to reduce their carbon footprint and promote a more sustainable way of doing business. One such company that is leading the charge in soft plastic recycling is [Company Name].[Company Name] is a pioneering leader in the field of environmental sustainability, with a strong focus on recycling and reducing waste. The company has developed cutting-edge technology and processes to recycle soft plastics, which are often difficult to recycle due to their composition and properties. By utilizing state-of-the-art equipment and machinery, [Company Name] has been able to process and recycle soft plastics, turning them into high-quality reusable materials.The process of soft plastic recycling begins with collecting and sorting the plastic waste. This is followed by cleaning, shredding, and then melting the plastic to form pellets, which can be used to manufacture new products. The company's advanced recycling facilities are designed to handle large volumes of soft plastic waste, ensuring maximum efficiency and minimal environmental impact.In addition to its recycling efforts, [Company Name] is committed to raising awareness about the importance of recycling and encouraging individuals and businesses to participate in sustainable practices. The company has implemented various educational and outreach programs to engage the community and promote a culture of recycling and environmental responsibility.One of the key initiatives of [Company Name] is its collaboration with local governments and non-profit organizations to establish collection points for soft plastic waste. These collection points are strategically placed in high-traffic areas such as supermarkets, shopping malls, and public spaces, making it convenient for people to dispose of their soft plastic waste in an environmentally responsible manner. By making recycling accessible and easy, [Company Name] is empowering individuals to take an active role in preserving the environment.Furthermore, [Company Name] has forged partnerships with major manufacturers and businesses to create a closed-loop system for recycling soft plastics. Through these partnerships, the company is able to collect, recycle, and reutilize soft plastics in the production process, effectively closing the loop and reducing the amount of plastic waste that ends up in landfills or oceans.The impact of [Company Name]'s efforts in soft plastic recycling goes beyond environmental benefits. By diverting soft plastics from landfills and repurposing them into reusable materials, the company is contributing to the circular economy and reducing the demand for virgin raw materials. This not only conserves natural resources but also helps to lower the carbon footprint associated with the production of new plastics.As a result of its commitment to sustainability and environmental stewardship, [Company Name] has been recognized for its outstanding contributions to soft plastic recycling. The company has received accolades and awards from industry organizations and government agencies, affirming its position as a leader in sustainable business practices.In conclusion, [Company Name] is at the forefront of soft plastic recycling, demonstrating a steadfast dedication to environmental sustainability and responsible waste management. Through its innovative recycling processes, educational initiatives, and strategic partnerships, the company is making a significant impact in reducing plastic waste and promoting a more sustainable future. With its unwavering commitment to the environment, [Company Name] is setting a shining example for businesses across the globe, proving that sustainability and profitability can go hand in hand.

High-Quality Profile Extrusion Line for Efficient Production

In today's rapidly evolving manufacturing industry, the demand for high-quality and efficient production equipment is higher than ever. To meet this need, {} is proud to introduce their state-of-the-art Profile Extrusion Line, designed to revolutionize the manufacturing process for a wide range of industries.With over [number] years of experience in the manufacturing and supply of machinery and equipment, {} has earned a reputation for delivering cutting-edge solutions that enhance efficiency, productivity, and product quality. The company's commitment to innovation and customer satisfaction has led them to develop the Profile Extrusion Line, a highly advanced system that promises to streamline the production of various profiles with unmatched precision and consistency.The Profile Extrusion Line boasts a range of features and capabilities that set it apart from traditional manufacturing equipment. Equipped with the latest in extrusion technology, this line is capable of producing a wide variety of profiles, including PVC, PE, PP, and other thermoplastic materials, with exceptional speed and accuracy. Its modular design allows for flexibility in production, enabling manufacturers to easily adapt to changing market demands and quickly switch between different profile shapes and sizes.One of the most notable features of the Profile Extrusion Line is its integrated control system, which enables real-time monitoring and adjustments to ensure optimal performance and product quality. This level of automation reduces the need for manual intervention, minimizing the risk of human error and maximizing overall production efficiency. Additionally, the line is designed with energy efficiency in mind, helping manufacturers reduce their carbon footprint and operational costs.In line with {}'s commitment to customer satisfaction, the Profile Extrusion Line is backed by comprehensive technical support and a team of dedicated experts who are readily available to provide assistance and guidance. This ensures that customers can maximize the potential of their equipment and achieve peak performance throughout its lifespan.The introduction of the Profile Extrusion Line marks a significant milestone for both {} and the manufacturing industry as a whole. By offering a more efficient and technologically advanced solution for profile production, this line has the potential to not only improve the capabilities of manufacturers but also drive innovation and progress in various end-user industries, such as construction, automotive, and consumer goods.As the global market continues to evolve and demand for high-quality profiles grows, the Profile Extrusion Line is poised to become a valuable asset for manufacturers seeking to stay ahead of the competition. Its ability to deliver consistent, high-quality results in a cost-effective and sustainable manner makes it an ideal investment for companies looking to enhance their production capabilities and meet the needs of an ever-changing market.With the introduction of the Profile Extrusion Line, {} once again demonstrates their commitment to pushing the boundaries of manufacturing technology and empowering their customers to thrive in a competitive marketplace. As the industry continues to evolve, it is innovations like this that will drive progress and shape the future of manufacturing for years to come.

Innovative Pellet Extruder Machine for Efficient Manufacturing Processes

In the fast-paced world of manufacturing and production, companies are constantly searching for innovative solutions to improve efficiency and quality. One such solution that has been making waves in the industry is the Pellet Extruder Machine from a leading manufacturer in the field of plastic extrusion machinery.This cutting-edge machine is designed to streamline the process of converting raw materials into high-quality pellets, which can be used in a wide range of applications, including injection molding, blow molding, and extrusion. By incorporating the latest technological advancements, this Pellet Extruder Machine has set a new standard for precision, speed, and reliability in the production of pellets.With a strong focus on research and development, the company behind this Pellet Extruder Machine has established itself as a global leader in the field of plastic extrusion machinery. With a track record of delivering innovative solutions to meet the evolving needs of the industry, the company has earned a reputation for excellence and reliability.The Pellet Extruder Machine is the result of years of expertise and experience, combined with a commitment to pushing the boundaries of what is possible in plastic extrusion technology. By integrating advanced automation and control systems, the machine offers unparalleled levels of accuracy and consistency, ensuring that every pellet produced meets the highest standards of quality.Furthermore, the Pellet Extruder Machine is designed with flexibility in mind, allowing for seamless integration into existing production lines and processes. This ensures that manufacturers can easily adapt to changing production demands and market trends, without compromising on efficiency or productivity.In addition to its technical capabilities, the Pellet Extruder Machine is also designed with user-friendliness in mind. With intuitive controls and a user-friendly interface, operators can easily monitor and adjust the machine to optimize performance and output. This not only improves the overall production process but also reduces the risk of errors and downtime.From a sustainability standpoint, the Pellet Extruder Machine also offers significant benefits. By optimizing the production process and minimizing waste, the machine helps companies reduce their environmental impact and operate more responsibly. This aligns with the company's commitment to promoting sustainable and eco-friendly manufacturing practices.Overall, the Pellet Extruder Machine represents a significant leap forward in the field of plastic extrusion machinery, offering unmatched levels of precision, efficiency, and sustainability. With its advanced technology and user-friendly design, it is poised to revolutionize the way manufacturers produce pellets for a wide range of applications.As the demand for high-quality pellets continues to grow across various industries, the Pellet Extruder Machine is well-positioned to meet this demand and set new standards for excellence in plastic extrusion technology. Backed by a leading manufacturer with a strong track record of innovation and reliability, the machine is set to make a lasting impact on the future of manufacturing and production.

Efficient Plastic Shredder Recycling Plant for Sustainable Waste Management

Plastic Shredder Recycling Plant Aims to Revolutionize Plastic Waste ManagementIn a world grappling with the ever-increasing problem of plastic pollution, one company is stepping up to the plate with a revolutionary solution. {Company Name}, a leader in environmental innovation, has recently unveiled their state-of-the-art plastic shredder recycling plant, a facility that promises to change the way plastic waste is managed and recycled.The new plant, located in the heart of the city, is equipped with cutting-edge technology that is capable of shredding and recycling large volumes of plastic waste. This innovative process allows for the efficient separation and processing of different types of plastic, making it a highly effective solution for managing plastic waste.{Company Name} has a long-standing commitment to environmental sustainability and has invested heavily in research and development to bring this revolutionary plastic shredder recycling plant to fruition. The company's dedication to innovation and environmental responsibility is evident in the design and capabilities of the plant, which is poised to play a significant role in the global effort to address plastic pollution.The plastic shredder recycling plant is viewed as a critical step forward in the company's mission to create a more sustainable future. By providing a solution for the recycling of plastic waste, {Company Name} aims to reduce the environmental impact of plastic pollution and contribute to the circular economy by turning waste into a valuable resource.The plant is also a testament to {Company Name}'s commitment to creating a greener and more sustainable world. Through the implementation of advanced recycling technology, the company is demonstrating its dedication to making a tangible difference in the fight against plastic pollution. This commitment extends beyond the plant itself, as {Company Name} has also been actively involved in community engagement and outreach programs focused on promoting environmental awareness and education.Furthermore, the plant is expected to have a positive economic impact by creating job opportunities and fostering innovation in the recycling industry. The investment in cutting-edge technology and infrastructure reflects {Company Name}'s belief that sustainable solutions can also be economically viable.{Company Name} is also collaborating with local governments, businesses, and communities to promote the responsible use and recycling of plastic. By working together with stakeholders, the company is seeking to create a comprehensive and sustainable approach to plastic waste management.The plastic shredder recycling plant is a significant milestone in {Company Name}'s ongoing efforts to lead the way in environmental innovation. With its commitment to sustainability, the company is firmly positioned as a catalyst for positive change in the global effort to address plastic pollution.As the plastic shredder recycling plant begins operations, the world is watching {Company Name} with great anticipation and hope. The plant represents a beacon of possibility—a solution to a problem that has long plagued our planet. With the unveiling of this innovative facility, {Company Name} has once again demonstrated its leadership in environmental stewardship and its dedication to creating a more sustainable future for all.In conclusion, the launch of the plastic shredder recycling plant is a testament to {Company Name}'s unwavering dedication to environmental sustainability and innovation. The facility is poised to revolutionize plastic waste management and make a significant impact on the global effort to combat plastic pollution. As the plant begins operations, {Company Name} is set to pave the way for a more sustainable future—one where plastic waste is no longer seen as a problem, but as a valuable resource.

Innovative Recycled Plastic Extruder: A Game-Changer in Sustainable Manufacturing

[Company Name] Introduces Innovative Recycled Plastic Extruder to Reduce Environmental ImpactIn today's global society, the issue of environmental sustainability has become a prominent concern. As businesses and industries continue to grow, so too does the amount of waste and pollution they produce. In response to this growing problem, [Company Name] has introduced an innovative solution to address the issue of plastic waste - a state-of-the-art Recycled Plastic Extruder.[Company Name] has long been a leading company in the field of sustainable and eco-friendly technologies. With a strong commitment to reducing their environmental impact, the company has dedicated significant resources to developing cutting-edge solutions for recycling and reusing plastic materials. Their latest innovation, the Recycled Plastic Extruder, is a testament to this commitment and represents a significant step forward in the fight against plastic pollution.The Recycled Plastic Extruder developed by [Company Name] is a technologically advanced machine that is capable of turning used plastic materials into high-quality recycled plastic pellets. These pellets can then be used as raw materials for the production of a wide range of plastic products, effectively closing the loop on the plastic waste cycle. By providing a practical and efficient method for recycling plastics, the Recycled Plastic Extruder helps to reduce the amount of plastic waste that ends up in landfills and oceans, thus mitigating the environmental impact of plastic pollution.One of the key features of [Company Name]'s Recycled Plastic Extruder is its advanced design and engineering. The machine is equipped with state-of-the-art technology that allows for the efficient and effective processing of various types of plastic materials, including PET, HDPE, and LDPE, among others. This versatility ensures that a wide range of plastic waste can be effectively recycled, reducing the need for virgin plastic production and minimizing the negative environmental effects associated with plastic manufacturing.Furthermore, the Recycled Plastic Extruder is designed with sustainability in mind. It is built to operate with a low energy consumption and minimal environmental impact, making it an environmentally friendly and economically viable solution for plastic recycling. This aligns with [Company Name]'s overarching commitment to sustainability and responsible environmental stewardship, further reinforcing the company's dedication to reducing their carbon footprint and promoting a circular economy.In addition to its environmental benefits, the Recycled Plastic Extruder also presents a number of economic advantages. By providing a cost-effective method for producing recycled plastic pellets, the machine offers businesses and manufacturers an opportunity to reduce their production costs while also contributing to the preservation of the environment. This makes the Recycled Plastic Extruder a valuable asset for companies looking to improve their sustainability practices and reduce their reliance on virgin plastic materials.[Company Name] is proud to introduce the Recycled Plastic Extruder as part of their ongoing efforts to promote environmental sustainability and responsible resource management. By offering a practical and efficient solution for recycling plastic materials, the company aims to make a meaningful impact on the global plastic waste crisis and contribute to the creation of a more sustainable and eco-friendly future.With the introduction of the Recycled Plastic Extruder, [Company Name] is poised to lead the way in the development and implementation of innovative technologies for plastic recycling. Through their continued commitment to environmental stewardship and sustainable business practices, the company is setting a new standard for responsible and eco-friendly manufacturing, inspiring others to follow suit in the pursuit of a cleaner and more sustainable world.

Innovative Pipe Coiler: An Efficient Solution for Coiling Pipes

[Reporter][Date][Header][Dateline]In a groundbreaking development for the pipe manufacturing industry, a cutting-edge pipe coiler has been unveiled by a company at the forefront of technological advancements. This state-of-the-art equipment, developed by [Company Name], is set to revolutionize the way pipes are produced, providing unmatched efficiency and precision.[Company Name], a pioneering force in the manufacturing sector, has always been committed to delivering innovative solutions. With its latest pipe coiler, the company aims to take pipe manufacturing to new heights, bringing about enhanced productivity and simplified operations.The newly launched pipe coiler is equipped with advanced features that make it an ideal choice for pipe manufacturers worldwide. Its automated capabilities ensure a streamlined and efficient production process. From the moment the raw material is fed into the machine to the final coiled product, every step is meticulously executed, maximizing output while minimizing wastage.One of the distinguishing features of this pipe coiler is its ability to handle a wide range of pipe sizes and materials. Whether it be PVC, HDPE, or any other material commonly used in pipe manufacturing, this versatile coiler can provide consistent and high-quality results. Moreover, the coiler can accommodate pipes of varying diameters and lengths, further adding to its flexibility and usefulness for manufacturers.The advanced technology integrated into this coiler ensures precise coiling, securing each pipe in an orderly and structured manner. This not only facilitates easy transportation and storage but also reduces the likelihood of damage during handling. The efficiency of the coiling process translates into time and cost savings for manufacturers, enabling them to greatly improve their overall productivity.[Company Name] has always been committed to prioritizing safety and sustainability, and the latest pipe coiler is no exception. Stringent safety measures have been incorporated into the machine's design, minimizing the risk of accidents during operation. Additionally, the coiling process itself eliminates the need for excessive packaging materials, contributing to a greener and more sustainable production approach.This pipe coiler is not only a symbol of technological advancement but also a testament to [Company Name]'s commitment to customer satisfaction. The company's dedication to excellence extends beyond product development, as it offers comprehensive customer support and maintenance services. By providing round-the-clock assistance, [Company Name] ensures that pipe manufacturers can rely on their investment for seamless operations.As the global demand for pipes continues to escalate, manufacturers are constantly seeking ways to improve their production capacity and efficiency. The introduction of this pipe coiler by [Company Name] is set to address these industry needs head-on, augmenting manufacturers' ability to meet market demands and stay ahead of the competition.With its exceptional features and unparalleled performance, the pipe coiler developed by [Company Name] is destined to transform the pipe manufacturing landscape. This groundbreaking technology will undoubtedly have a lasting impact on the industry, setting new benchmarks for efficiency, quality, and sustainability.In conclusion, [Company Name] has once again distinguished itself as an industry leader through their innovative advancements. The launch of the pipe coiler represents a significant step forward for pipe manufacturers worldwide, revolutionizing their processes and redefining performance expectations. As the industry adapts to this cutting-edge technology, the future of pipe manufacturing looks brighter than ever before.[End]

Powerful Recycling Shredder: A Game Changer in Waste Management

Recycling Shredder Supports Company's Commitment to SustainabilityIn a world that is increasingly aware of the need to reduce waste and protect the environment, more and more companies are looking for innovative ways to incorporate sustainability into their business practices. One such company, [], has taken a proactive approach to this issue by investing in a state-of-the-art recycling shredder. This cutting-edge equipment not only supports the company's commitment to sustainability but also sets a new standard for responsible manufacturing and waste management.The recycling shredder, which is a key component of the company's waste reduction and recycling efforts, is capable of processing a wide range of materials, including plastic, metal, and paper. This versatility allows [] to significantly reduce the volume of waste it sends to landfills, while also recovering valuable raw materials that can be used in the production of new products. By embracing the principles of the circular economy, the company is not only reducing its environmental impact but also contributing to the conservation of natural resources.In addition to its environmental benefits, the recycling shredder plays a crucial role in helping [] minimize its carbon footprint. By processing materials on-site, the company reduces the need for transportation and decreases the emissions associated with waste disposal. This localized approach to waste management also allows [] to maintain greater control over its recycling processes, ensuring that materials are handled responsibly and in accordance with the highest environmental standards.The decision to invest in a recycling shredder is just one example of []'s ongoing commitment to sustainability. The company has implemented a range of initiatives aimed at reducing waste and energy consumption across its operations, from the use of renewable energy sources to the implementation of water conservation measures. By embracing sustainable practices at every level of its business, [] is not only working to minimize its environmental impact but also setting an example for others in the industry to follow.Furthermore, the investment in the recycling shredder has allowed [] to expand its product portfolio, incorporating recycled materials into a wide range of new and existing products. This not only demonstrates the company's dedication to sustainable manufacturing but also provides customers with environmentally-friendly options that align with their own values and preferences. By offering products that are both high-quality and eco-friendly, [] is meeting the growing demand for sustainable alternatives in the marketplace.In line with its commitment to transparency, [] has been open about its efforts to incorporate sustainable practices into its business model. The company regularly communicates its progress in sustainability through its website, social media channels, and annual reports, creating a dialogue with stakeholders about the importance of environmental responsibility. By sharing its journey towards sustainability, [] hopes to inspire others to take similar steps towards reducing their environmental impact and embracing more sustainable business practices.As the global community continues to grapple with the challenges of climate change and environmental degradation, businesses have a critical role to play in finding solutions that support a more sustainable future. The investment in a recycling shredder is a clear demonstration of []'s dedication to this cause, and the company's leadership in this area has the potential to influence the wider industry. By prioritizing sustainability and taking actionable steps to reduce waste, [] is setting a positive example for its peers and helping to drive meaningful change in the business world.In conclusion, the introduction of a recycling shredder marks a significant milestone in []'s sustainability journey, demonstrating the company's commitment to reducing its environmental impact and embracing more responsible business practices. By investing in cutting-edge recycling technology, [] is not only minimizing its waste and carbon footprint but also creating opportunities to incorporate recycled materials into its product offerings. As companies around the world seek to adopt more sustainable practices, [] is leading the way by integrating sustainability into every aspect of its operations.

Efficient and Eco-Friendly Pet Flakes Washing Machine for Recycling Industry

Pet Flakes Washing Machine, an innovative solution to plastic waste management, is a revolutionary step towards a sustainable future. This advanced machine is designed to effectively clean and recycle PET (Polyethylene Terephthalate) flakes, thereby contributing to the reduction of plastic pollution. The company, a leading manufacturer of industrial machinery, is dedicated to providing cutting-edge technology for environmental conservation and sustainable development.With the increasing global concern over plastic waste, the demand for efficient recycling solutions has never been greater. The Pet Flakes Washing Machine addresses this pressing issue by offering an efficient and cost-effective method for cleaning and processing PET flakes. This not only helps in reducing the environmental impact of plastic waste but also contributes to the circular economy by promoting the reuse of materials.The machine is equipped with advanced washing and drying equipment, which ensures that the PET flakes are thoroughly cleaned and prepared for further processing. Its efficient filtration and separation system effectively removes contaminants and impurities, resulting in high-quality recycled PET flakes. The entire process is automated, ensuring consistency and reliability in the output.In addition to its technological prowess, the company behind the Pet Flakes Washing Machine is committed to sustainability and environmental responsibility. Their dedication to research and development has led to the creation of a machine that not only meets industry standards but also prioritizes energy efficiency and resource conservation. By utilizing this machine, businesses can not only contribute to the reduction of plastic waste but also improve their overall environmental footprint.The company's approach to sustainability extends beyond just the design of the machine. They also offer comprehensive support and training for their clients, empowering them to effectively operate and maintain the equipment. This commitment to customer satisfaction ensures that businesses can seamlessly integrate the Pet Flakes Washing Machine into their operations, further promoting sustainable practices within the industry.Furthermore, the company's focus on innovation and continuous improvement sets them apart in the market. They constantly strive to enhance their products and services, staying at the forefront of technological advancements in the field of plastic recycling. This dedication to excellence positions them as a reliable and forward-thinking partner for businesses seeking to invest in sustainable solutions.The Pet Flakes Washing Machine is not just a piece of equipment; it represents a significant step towards a cleaner and greener future. By offering a viable and efficient solution for PET flake recycling, the company is contributing to the global efforts to mitigate the environmental impact of plastic waste. With their commitment to sustainability, innovation, and customer satisfaction, they are poised to make a lasting impact on the industry and the planet.As the world continues to grapple with the challenges posed by plastic waste, the introduction of the Pet Flakes Washing Machine brings a ray of hope. It showcases the potential for technology to drive positive change and offers a tangible solution for businesses looking to embrace sustainability. With the support and expertise of the company behind this groundbreaking innovation, the adoption of this technology is set to make a meaningful difference in the fight against plastic pollution.

Revolutionary Plastic Oil Bottle Recycling: A Sustainable Solution for a Greener Future

Title: Innovations in Plastic Oil Bottle Recycling Aim Towards Sustainable FutureIntroduction:In the pursuit of a more sustainable future, recycling plastic oil bottles has taken center stage. Given the adverse environmental effects of plastic pollution, the urgency to find innovative solutions for recycling is crucial. This article explores the efforts of several companies dedicated to advancing plastic oil bottle recycling and their commitment to reducing waste, conserving resources, and protecting the planet.Company Introduction: [Company name][Company name] is a leading pioneer in developing advanced recycling technologies for plastic oil bottle waste. Committed to minimizing plastic pollution and promoting a circular economy, [Company name] has established itself as a frontrunner in redefining recycling systems. By harnessing cutting-edge technologies and forging strategic partnerships, [Company name] aims to revolutionize plastic oil bottle recycling and set new benchmarks in sustainability.1. Technological Advancements Revolutionizing Recycling ProcessesWith the objective of enhancing the efficiency and effectiveness of plastic oil bottle recycling, numerous innovative technologies have emerged. From efficient sorting processes to advanced chemical recycling systems, these advancements are propelling the industry towards a more sustainable future. [Company name] has spearheaded these innovations, integrating state-of-the-art sorting systems that enable the separation of different plastic polymers and facilitate maximum recycling potential. Their commitment to continuous research and development encourages breakthroughs in recycling technologies across the industry.2. Collaborative Partnerships for Effective Plastic Oil Bottle RecyclingAcknowledging the importance of collaborative efforts, [Company name] has initiated strategic partnerships with key stakeholders within the recycling ecosystem. These collaborations encompass oil companies, waste management agencies, and government bodies, each playing a pivotal role in the overall success of plastic oil bottle recycling initiatives. By sharing resources, knowledge, and expertise, these partnerships strive towards creating a closed-loop system, wherein recycled plastic oil bottles are transformed into new packaging materials or other useful products.3. Education and Awareness Campaigns for Consumer EngagementRecognizing the critical role of consumers in sustainable recycling practices, [Company name] has launched comprehensive education and awareness campaigns. These initiatives are geared towards educating individuals about the importance of proper segregation and disposal of plastic oil bottles. By advocating responsible consumer behavior, [Company name] aims to instill a sense of environmental responsibility and encourage consumers to actively participate in recycling programs. Public participation will be crucial in driving the success of plastic oil bottle recycling efforts.4. Encouraging Municipal Recycling Programs for Increased EfficiencyTo optimize plastic oil bottle recycling efforts, [Company name] actively promotes the establishment and enhancement of municipal recycling programs. Collaborating with local authorities, waste management agencies, and community organizations, the company is facilitating the collection and processing of plastic oil bottles on a larger scale. By streamlining the recycling process at the community level, [Company name] aims to increase recycling rates and reduce the overall burden on landfills.5. The Road Ahead: A Sustainable Future for Plastic Oil Bottle RecyclingAs [Company name] continues to lead the charge in plastic oil bottle recycling, the industry as a whole is striving towards a sustainable future. Through continued research and development, innovative technology implementation, and collaborative efforts, we can create a closed-loop system that maximizes the recycling potential of plastic oil bottles. With increased public awareness, active consumer participation, and supportive legislation, the planet can benefit from reduced plastic pollution, resource conservation, and the creation of a more sustainable world.Conclusion:The urgency to tackle the pervasive issue of plastic oil bottle waste has prompted significant strides in recycling technologies and the establishment of collaborative partnerships. [Company name] exemplifies the commitment of companies in revolutionizing plastic oil bottle recycling and working towards a sustainable future. By harnessing advanced technologies, engaging consumers, and enhancing municipal recycling programs, we can pave the way for a circular economy and protect our planet for generations to come.

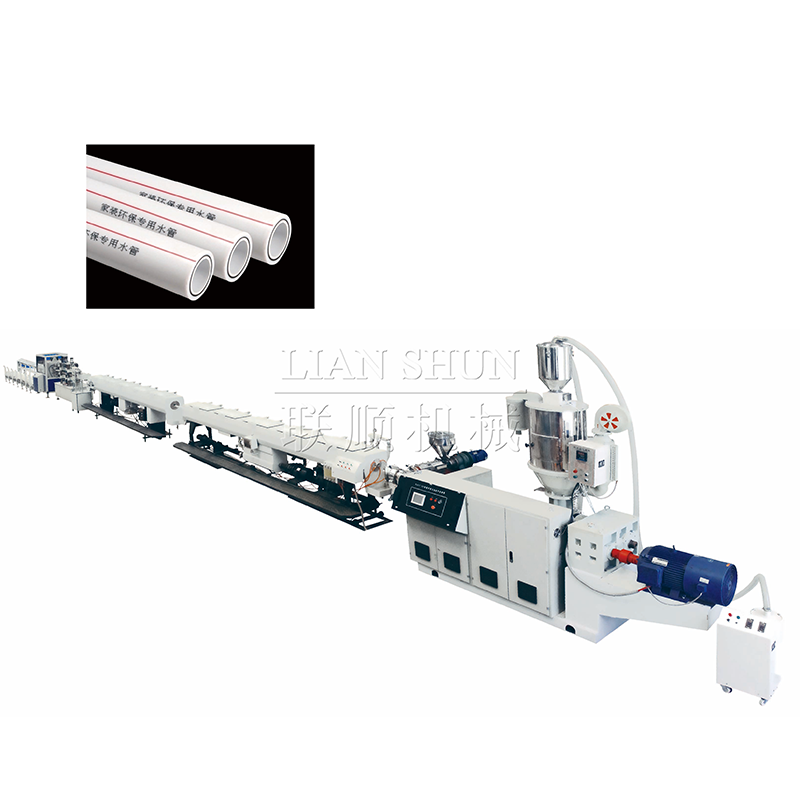

Efficient Manufacturing Machine for Electrical PVC Pipe Production Unveiled

Title: Revolutionary Electrical PVC Pipe Manufacturing Machine Set to Transform the IndustryIntroduction:In a bid to revolutionize the Electrical PVC Pipe Manufacturing industry, a renowned manufacturing company has developed an innovative machine that promises to streamline the production process while maintaining the highest standards of quality and efficiency. By integrating cutting-edge technology, this groundbreaking device aims to enhance productivity levels, reduce resource consumption, and meet the increasing demands of the market. This article delves into the key features and potential benefits of this game-changing manufacturing machine.Section 1: Background and Industry Overview (150 words)The Electrical PVC Pipe Manufacturing industry has experienced steady growth in recent years due to the increasing demand for electrical infrastructure in both commercial and residential sectors. Traditionally, the manufacturing process involved multiple stages, leading to higher production costs and longer lead times. However, with technological advancements paving the way for innovation, companies are constantly seeking ways to optimize their manufacturing processes.Section 2: Introduction of the Electrical PVC Pipe Manufacturing Machine (150 words)The new Electrical PVC Pipe Manufacturing Machine brings a fresh perspective to the industry by leveraging state-of-the-art technology. This fully automated machine is designed to integrate various production processes, from raw material preparation to final product packaging, into a single streamlined operation. By eliminating the need for manual labor and multiple machines, this device promises to significantly enhance productivity levels, reduce production time, and offer superior quality control.Section 3: Features and Benefits of the Electrical PVC Pipe Manufacturing Machine (250 words)- Advanced Technology: The manufacturing machine utilizes cutting-edge technology, including computer numerical control (CNC) systems, to ensure precise and consistent pipe production. This technology enables measurements and adjustments to be made with unprecedented accuracy, resulting in high-quality end products.- Enhanced Efficiency: Through the integration of various processes into a single operation, the machine maximizes efficiency by minimizing the time required for material handling, equipment setup, and changeovers. This leads to higher production rates, shorter lead times, and reduced manufacturing costs.- Quality Assurance: The machine incorporates automatic quality control mechanisms, which continually monitor and adjust key parameters during the manufacturing process. With this feature, manufacturers can ensure that each PVC pipe produced meets the required specifications, leading to improved customer satisfaction.- Eco-Friendly Operation: The machine is designed with sustainability in mind. Its energy-efficient systems and optimized resource consumption minimize waste, reducing the overall environmental impact of the manufacturing process.- Versatile Production: The machine is adaptable to various pipe sizes and specifications, allowing manufacturers to cater to a wide range of customer requirements. This flexibility ensures a competitive edge in the market, enabling companies to respond quickly to evolving industry demands.Section 4: Conclusion (100 words)The introduction of the Electrical PVC Pipe Manufacturing Machine signifies a milestone in the evolution of the industry. By combining advanced technology, streamlined processes, and environmental sustainability, this game-changing device has the potential to revolutionize the manufacturing landscape. As companies seek ways to increase productivity, reduce costs, and meet customer demands, the utilization of this machine could serve as a catalyst for success in the highly competitive Electrical PVC Pipe Manufacturing industry.