Find plastic extruders near your location for all your needs

By:Admin

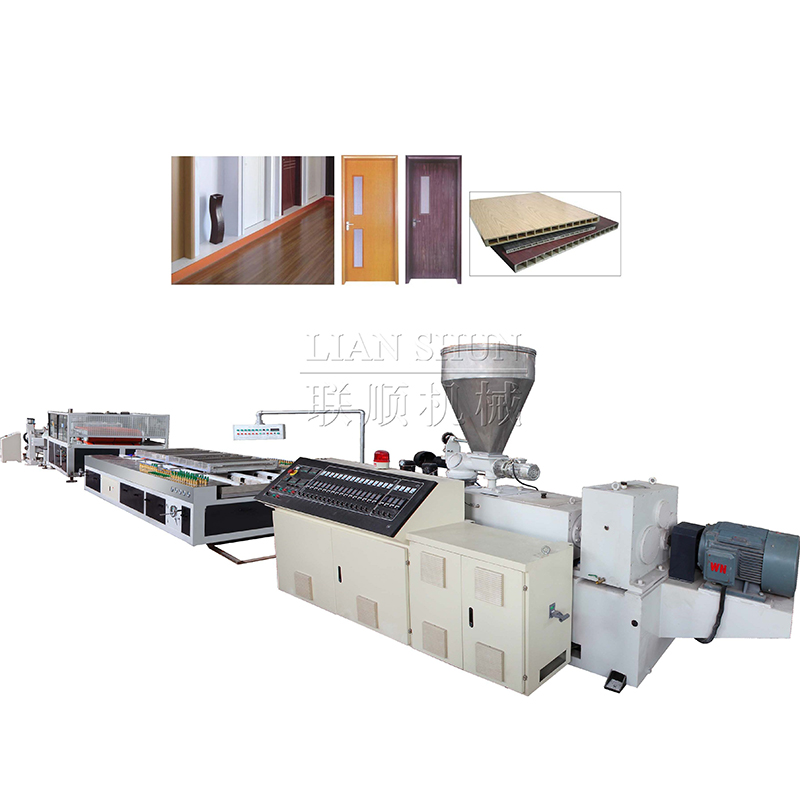

In the market for plastic extruders, there is a growing demand for high-quality machines that are reliable, efficient, and cost-effective. As a result, many companies are searching for reputable and reliable manufacturers of plastic extruders that are located near their operational base.

One such manufacturer that has been gaining attention in the industry is {}. Founded in {}, the company has established itself as a leading provider of plastic extrusion equipment and has built a strong reputation for delivering top-quality machines and excellent customer service.

The company's extensive product line includes a variety of plastic extruders, ranging from single screw extruders to co-extruders, and is suitable for producing a wide range of plastic products. These machines are designed to meet the diverse needs of their customers and are known for their efficiency, reliability, and durability.

One of the key factors that set {} apart from other manufacturers is their commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking new ways to enhance their machines' performance and capabilities. This dedication to innovation has allowed {} to stay at the forefront of technological advancements in the industry and ensures that their customers have access to state-of-the-art equipment.

In addition to their focus on innovation, {} also places a strong emphasis on quality control and adherence to industry standards. All of their machines undergo rigorous testing and inspection procedures to ensure that they meet the highest quality standards. This commitment to quality has earned the company various certifications and accreditations, solidifying their position as a trusted and reputable manufacturer in the industry.

Furthermore, {} takes pride in its customer-centric approach and is dedicated to providing exceptional service to its clients. The company has a team of knowledgeable and experienced professionals who are readily available to provide technical support, guidance, and training to their customers. This level of support allows their clients to maximize the performance and efficiency of their plastic extruders, ultimately leading to increased productivity and profitability.

It's also worth noting that {} is committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize its environmental impact and reduce waste in its manufacturing processes. This demonstrates their commitment to creating a greener and more sustainable future for the industry.

As a result of these factors, {} has been attracting attention from companies in search of reliable and reputable manufacturers of plastic extruders. Their dedication to quality, innovation, and customer satisfaction has set them apart as a leading provider of plastic extrusion equipment.

With the increasing demand for high-quality plastic extruders, {} is well-positioned to meet the needs of the industry and continue to grow its presence in the market. With a strong focus on innovation, quality, and customer service, the company is poised to remain a top choice for companies seeking reliable and efficient plastic extrusion equipment.

In conclusion, the demand for plastic extruders continues to grow, and companies are constantly searching for reputable manufacturers that can provide high-quality and reliable machines. {}. With its commitment to innovation, quality, and customer satisfaction, the company has established itself as a leading provider of plastic extrusion equipment and is well-positioned to meet the evolving needs of the industry.

Company News & Blog

Plastic Extrusion Machine: The Key to Efficient Extrusion Processes

Plastic Extrusion Machine: Revolutionizing the Manufacturing IndustryIn an era characterized by technological advancements, the manufacturing industry is constantly exploring innovative ways to optimize productivity and improve product quality. One such method that has gained immense popularity is plastic extrusion, facilitated by the Plastic Extrusion Machine, also known as an extruder. This machine has revolutionized the manufacturing industry by providing unprecedented flexibility and efficiency in producing a wide range of plastic products.Plastic extrusion is the process of melting raw plastic materials and shaping them into a continuous profile, allowing for the creation of various products such as pipes, tubes, sheets, films, and even complex profiles. The Plastic Extrusion Machine, also referred to as the extruder, is at the heart of this process, playing a pivotal role in transforming raw plastic materials into the desired end products.One prominent player in the manufacturing industry that has made significant contributions to the development and production of Plastic Extrusion Machines is {}. With a rich history dating back to {}, they have established themselves as a leader in designing and manufacturing high-quality extruders that cater to a diverse range of industries.With a meticulous attention to detail and an unwavering commitment to customer satisfaction, {} has consistently focused on delivering cutting-edge technology and unrivaled performance in their Plastic Extrusion Machines. These machines are renowned for their durability, accuracy, and seamless performance, enabling businesses to achieve unprecedented levels of productivity and efficiency.In order to cater to the varying needs of different industries, {} has developed a comprehensive portfolio of Plastic Extrusion Machines. This includes single-screw extruders, which are ideal for simpler profiles and basic applications, as well as twin-screw extruders that offer unparalleled versatility and unparalleled process control, making them suitable for complex shapes and demanding applications.The Plastic Extrusion Machines offered by {} are equipped with state-of-the-art features and technologies, ensuring optimum performance and ease of operation. These machines boast advanced temperature control systems, precise pressure and speed control mechanisms, and efficient melt filtration systems, all of which contribute to the production of high-quality plastic products.One notable aspect of {}'s Plastic Extrusion Machines is their adaptability to different plastic materials, including PVC, HDPE, LDPE, PP, and ABS, among others. This versatility allows businesses to explore a wide range of applications and expand their product offerings, catering to diverse market demands.Beyond the remarkable technical capabilities of their Plastic Extrusion Machines, {} is committed to environmentally responsible manufacturing practices. Their extruders are designed to minimize energy consumption, reduce waste generation, and optimize resource utilization. By embracing sustainable methods of production, {} aims to contribute to a greener and more sustainable future for the manufacturing industry.In addition to providing exceptional Plastic Extrusion Machines, {} offers comprehensive technical support and after-sales services to their customers. This includes installation assistance, operator training, maintenance services, and spare parts availability, ensuring uninterrupted productivity and long-term reliability of the machines.The enduring commitment to excellence and customer satisfaction has made {} a preferred choice for businesses seeking reliable Plastic Extrusion Machines. The company's constant drive for innovation and continuous investment in research and development have positioned them at the forefront of the manufacturing industry, setting new benchmarks of excellence.In conclusion, Plastic Extrusion Machines, such as those offered by {}, have revolutionized the manufacturing industry by enabling efficient and versatile production of a wide range of plastic products. With their cutting-edge technology, unrivaled performance, and commitment to sustainability, {} has emerged as a leader in this field, providing businesses with the means to enhance productivity, diversify offerings, and meet the evolving demands of the market.

High Quality PVC Pipe Extrusion Machine for Sale - Find the Best Deal Today!

Pvc Pipe Extrusion Machine For SaleAt present, the demand for PVC pipes has increased significantly in the construction and infrastructure sectors due to their durability, low cost, and effectiveness in transporting fluids and chemicals. As a result, the demand for PVC pipe extrusion machines has also surged, as manufacturers seek to meet the growing market needs. In response to this demand, a leading machinery manufacturing company has announced the availability of its high-quality PVC pipe extrusion machine for sale.The {Company Name} is renowned for its expertise in designing and manufacturing innovative machinery for the plastic processing industry. With a focus on delivering precision, efficiency, and reliability, the company has become a trusted partner for businesses seeking cost-effective and high-performance solutions for PVC pipe production. The newly available PVC pipe extrusion machine is a testament to the company's commitment to providing advanced technology to enhance the productivity and quality of plastic pipe manufacturing.This state-of-the-art PVC pipe extrusion machine is equipped with advanced features and capabilities to meet the evolving needs of the plastic processing industry. It is designed to optimize the production process by ensuring consistent output, precise dimensions, and high structural integrity of the PVC pipes. The machine is capable of handling a wide range of PVC raw materials, making it versatile and adaptable to various production requirements.The extrusion process is at the core of PVC pipe manufacturing, and the {Company Name} has integrated cutting-edge technology into its machine to ensure superior performance. The machine's extrusion system is engineered to deliver high output rates while maintaining energy efficiency, resulting in cost-effective production for manufacturers. Additionally, the machine's control systems are designed for user-friendly operation, enabling operators to monitor and adjust production parameters with ease.Furthermore, the {Company Name} takes pride in its commitment to quality and durability, reflected in the construction of the PVC pipe extrusion machine. By utilizing premium materials and robust engineering, the machine is built to withstand the rigors of continuous production, ensuring longevity and minimal downtime for manufacturers. This reliability is paramount for businesses seeking a dependable solution for their PVC pipe manufacturing operations.In addition to the machine's technical capabilities, the {Company Name} also provides comprehensive support and service to its customers. From installation and training to maintenance and technical assistance, the company's team of experts is dedicated to ensuring that customers derive maximum value from their investment in the PVC pipe extrusion machine. This commitment to customer satisfaction has earned the {Company Name} a reputation for excellence in the plastic processing industry.As the demand for PVC pipes continues to grow, the availability of high-quality PVC pipe extrusion machines becomes increasingly crucial for manufacturers striving to meet market requirements. With its latest offering, the {Company Name} reaffirms its position as a leading provider of advanced machinery for the plastic processing industry. The PVC pipe extrusion machine for sale represents an opportunity for businesses to enhance their production capabilities and capitalize on the growing demand for PVC pipes.In conclusion, the {Company Name}'s PVC pipe extrusion machine for sale is a testament to the company's dedication to innovation, quality, and customer satisfaction. With its advanced features, robust construction, and comprehensive support, the machine serves as an ideal solution for manufacturers seeking to upscale their PVC pipe production. As the industry continues to evolve, the {Company Name} remains at the forefront, delivering cutting-edge technology to empower businesses in the plastic processing sector.

Efficient HDPE Washing Line for Effective Recycling Processes

Title: Innovative HDPE Washing Line Revolutionizes Plastic Recycling IndustryIntroduction:In today's era of heightened environmental consciousness, the need for sustainable solutions is more pressing than ever. In the quest for a greener future, one company is paving the way with its groundbreaking HDPE Washing Line. By transforming plastic waste into high-quality recycled materials, they are making significant contributions towards reducing plastic pollution and conserving valuable resources.Company Background:Established in [year], [Company Name] has emerged as a leading name in the recycling industry, with a focus on HDPE (High-Density Polyethylene). Recognizing the urgent need to address the global plastic crisis, they have combined state-of-the-art technology with their extensive expertise to create an efficient HDPE Washing Line that sets new industry standards.[Company Name] prides itself on its commitment to sustainability, driven by its core values of innovation, impeccable quality, and environmental consciousness. Their dynamic team of engineers, researchers, and technicians continuously work towards developing and improving recyclable solutions that address the challenges posed by plastic waste on both local and global scales.The Revolutionary HDPE Washing Line:[Company Name]'s HDPE Washing Line is a game-changer in the plastic recycling industry due to several unique features and innovations. This advanced system offers a comprehensive solution for effectively cleaning, separating, and reprocessing HDPE waste, enabling their transformation into high-quality recycled materials.1. Cutting-Edge Sorting Technology:The HDPE Washing Line incorporates cutting-edge sorting technology, ensuring that only clean and pure HDPE plastic flakes are obtained. Utilizing a combination of automated processes, including optical sorting and gravity separation, this system effectively removes contaminants such as labels, caps, and other impurities.2. Waterless Washing Process:What sets [Company Name]'s HDPE Washing Line apart is its waterless washing process. By eliminating the traditional water-intensive washing methods, which consume vast amounts of water and energy, this system dramatically reduces the environmental impact associated with plastic recycling. Moreover, the elimination of water also minimizes the risk of water contamination during the recycling process.3. Increased Efficiency and Productivity:[Company Name]'s HDPE Washing Line is designed for maximum efficiency, achieving high productivity rates without compromising on the quality of the recycled output. The system streamlines various stages of the recycling process, from shredding and washing to drying and pelletizing, ensuring a seamless and highly effective operation.4. End-Product Integrity:The HDPE Washing Line guarantees the production of high-quality recycled HDPE materials. With controlled processes and stringent quality checks, both the mechanical and physical properties of the recycled plastic are preserved, maintaining the same strength, durability, and resilience as virgin HDPE. This ensures that the recycled materials can be used in a wide range of applications without compromising performance.5. Economic and Environmental Benefits:By investing in [Company Name]'s HDPE Washing Line, recycling facilities not only contribute to a cleaner environment but also unlock economic benefits. The high-quality recycled HDPE materials produced by the system have a wide range of applications, including packaging, construction, automotive, and more. This presents enormous market opportunities, reduces the demand for virgin plastic, and contributes to a circular economy.Conclusion:[Company Name]'s innovative HDPE Washing Line has revolutionized the plastic recycling industry, offering a sustainable solution for tackling the global plastic crisis. By combining cutting-edge technology, waterless processes, and a commitment to environmental consciousness, they have set new industry standards while promoting economic growth and a greener future. With these advancements, the company is driving the transformation towards a more sustainable and circular plastic economy.

Enhance Your Pipe Production with a Cutting-Edge Extrusion Machine

Title: Revolutionizing Pipe Manufacturing through Innovative Extrusion TechnologyIntroduction:In an era of rapid industrialization and urbanization, the demand for high-quality pipes for various applications has been escalating. To cater to this growing need, the pioneering engineers at a leading manufacturing company have developed an advanced Pipe Extrusion Machine capable of revolutionizing the pipe manufacturing industry. By leveraging cutting-edge technology and adhering to stringent quality standards, this innovation promises to deliver durable and efficient pipes for a wide range of industrial, commercial, and residential applications.Innovative Features:The advanced Pipe Extrusion Machine eliminates the traditional bottlenecks and challenges associated with pipe production. With an optimal combination of precision engineering and automation, this state-of-the-art machine can seamlessly manufacture pipes with exceptional precision, consistency, and strength. Its key features include:Advanced Extrusion Technology: The machine harnesses advanced extrusion technology, which ensures a smooth and continuous flow of raw materials, resulting in pipes with uniform thickness and excellent surface finish. The extrusion process guarantees consistent quality across the entire length of the pipe, enabling manufacturers to deliver high-performance products.Integrated Control System: Equipped with an intelligent and intuitive control system, the Pipe Extrusion Machine enables seamless adjustments throughout the manufacturing process. Manufacturers can easily regulate parameters such as temperature, pressure, and speed, ensuring total control over the pipe's physical attributes to meet specific application requirements.Versatility: The machine can produce pipes of various diameters and lengths, catering to a wide range of applications such as water supply, drainage, gas transportation, telecommunications, and more. Its versatility allows manufacturers to diversify their product offerings to meet market demand efficiently.High Productivity: With an optimized production cycle, this cutting-edge machine ensures maximum efficiency. It minimizes downtime while increasing output, enabling manufacturers to fulfill large-scale orders without compromising on quality. The high productivity not only boosts profitability but also strengthens the competitiveness of pipe manufacturers in the market.Quality Assurance: The Pipe Extrusion Machine incorporates an advanced quality control mechanism that continually monitors the production process to guarantee product consistency and uniformity. This adherence to quality standards ensures that the pipes produced possess exceptional durability, resistance to environmental factors, and long service life.Sustainable Manufacturing: Environmentally conscious, the machine incorporates energy-efficient processes, reducing power consumption and minimizing the carbon footprint. By promoting sustainable manufacturing practices, it contributes to a greener future for the pipe manufacturing industry.Company Overview:With an impressive track record spanning several decades, {}, a renowned industry leader, continues to revolutionize the field of pipe manufacturing. Committed to driving innovation and meeting market demands, the company has continuously invested in research and development, resulting in breakthrough products like the Pipe Extrusion Machine.Devoted to maintaining the highest standards, the company ensures stringent quality control throughout every stage of the manufacturing process. By combining cutting-edge technology, expert craftsmanship, and market insights, {} has successfully established itself as a trusted partner for high-quality pipes.Outlook and Conclusion:The introduction of the Pipe Extrusion Machine by {} marks a significant step forward in the pipe manufacturing industry. With its innovative features and commitment to quality, this advanced technology is poised to address the increasing demand for durable and efficient pipes.Manufacturers can benefit from the machine's versatility, high productivity, and stringent quality control, enhancing their competitiveness and expanding their market share. Furthermore, the machine's sustainable manufacturing practices highlight the importance of environmental consciousness in the industry.As the global infrastructure development continues to expand, the Pipe Extrusion Machine promises to play a crucial role in meeting the evolving needs of various sectors. With its capacity to produce high-performance pipes tailored to specific applications, this innovation is set to revolutionize the way pipes are manufactured, ensuring a reliable and sustainable future for the industry.

Understanding the Cost of Extruder Machines: What You Need to Know

Cost Of Extruder MachineThe cost of an extruder machine is a crucial consideration for companies in the manufacturing and processing industries. Extruder machines are utilized in various industries for the production of a wide range of products including food items, plastic materials, rubber, and more. The cost of an extruder machine can vary depending on several factors such as size, capacity, features, and brand. One of the leading manufacturers of extruder machines is [Company Name]. With over [X] years of experience in the industry, [Company Name] has a reputation for producing high-quality and innovative extruder machines that cater to the diverse needs of their customers. As a company, [Company Name] is committed to providing their customers with state-of-the-art extruder machines that are not only efficient but also cost-effective.When it comes to the cost of extruder machines, it is important to consider the specific requirements of the manufacturing or processing operations. The cost of an extruder machine can range from a few thousand dollars to several hundred thousand dollars. The size and capacity of the machine play a significant role in determining the cost, with larger and more powerful machines typically being more expensive.In addition to size and capacity, the features and capabilities of the extruder machine can also impact its cost. Extruder machines come with a variety of features such as advanced control systems, multiple extrusion capabilities, automated functions, and more. These features can add to the overall cost of the machine but are often essential for companies looking to optimize their production processes.Furthermore, the brand of the extruder machine can also influence its cost. While there are numerous manufacturers of extruder machines in the market, established and reputable brands like [Company Name] may come with a higher price tag due to their quality, reliability, and after-sales support. However, investing in a well-known brand can also provide companies with the assurance of superior performance and longevity.It is also important to note that the cost of an extruder machine is not limited to its initial purchase price. Companies must consider additional expenses such as installation, training, maintenance, and ongoing operational costs. These factors should be carefully evaluated to ensure that the total cost of ownership of the extruder machine aligns with the company's budget and operational requirements.In conclusion, the cost of an extruder machine can vary based on factors such as size, capacity, features, and brand. As a leading manufacturer in the industry, [Company Name] is dedicated to providing their customers with cost-effective extruder machines that deliver exceptional performance and value. By understanding their specific production needs and carefully evaluating the various cost considerations, companies can make informed decisions when investing in an extruder machine that will contribute to their success and growth in the industry.

Pipe Belling Machine: A Revolutionary Tool for Efficient Pipe Manufacturing

Title: Cutting-Edge Pipe Belling Machine Revolutionizes the Manufacturing ProcessIntroduction (100 words):In a groundbreaking move towards enhancing manufacturing capabilities, Company XYZ has recently introduced their innovative Pipe Belling Machine. This state-of-the-art technology is poised to revolutionize the pipe manufacturing industry. With a focus on efficiency, precision, and versatility, this machine is set to streamline production processes and deliver impeccable quality. Company XYZ's commitment to technological advancements is evident in the development of this cutting-edge machine, which aims to offer a cost-effective, time-saving, and reliable solution for pipe belling requirements.Paragraph 1 (100 words):The Pipe Belling Machine by Company XYZ is an engineering marvel that offers unparalleled efficiency and precision. Designed to automate the pipe bell-formation process, this machine eliminates the need for labor-intensive manual labor, reducing production time and costs significantly. The reliable and consistent performance of this machine ensures a streamlined manufacturing process, maintaining strict adherence to quality standards. Moreover, the sleek and compact design of the Pipe Belling Machine allows for easy installation and compatibility with various pipe dimensions, enabling manufacturers to meet diverse customer requirements seamlessly.Paragraph 2 (100 words):The Pipe Belling Machine offers a range of advanced features that set it apart from conventional options currently available on the market. Equipped with state-of-the-art technology, this machine leverages computer numerical control (CNC) systems to achieve unparalleled precision throughout the belling process. This guarantees accurate measurements and identical belling dimensions for each pipe, further bolstering the quality of the final product. Additionally, the machine is capable of adapting to various belling methods, including socket, spigot, and flaring, providing manufacturers with flexibility and versatility, catering to a wide array of customer demands.Paragraph 3 (150 words):The Pipe Belling Machine's user-friendly interface and intuitive controls make it accessible to operators of varying skill levels. Its easy-to-navigate touchscreen panel enables efficient machine operation and reduces the potential for errors. With automatic feeding mechanisms and real-time monitoring of critical parameters, this machine not only enhances productivity but also minimizes material wastage. Furthermore, the machine's robust construction ensures durability and longevity, promising reliable performance over an extended period.Paragraph 4 (150 words):Company XYZ's commitment to customer satisfaction is evident in its after-sales support and assistance. A team of highly skilled technicians is readily available to provide installation guidance, comprehensive training, and prompt maintenance services for the Pipe Belling Machines. This ensures that manufacturers can integrate the machine seamlessly into their production line and maximize its efficiency.Conclusion (100 words):The introduction of Company XYZ's Pipe Belling Machine signifies a significant leap in manufacturing technology. By combining innovative features with a robust design, this machine offers unmatched efficiency, precision, and versatility. Manufacturers can now streamline their production processes with greater ease, reducing costs, and enhancing overall product quality. Company XYZ's dedication to customer service and support further ensures a seamless integration of this cutting-edge technology into existing operations. With a proven track record of pioneering advancements, Company XYZ remains committed to revolutionizing the pipe manufacturing industry while maintaining the highest levels of customer satisfaction.

Bottle Crusher Machine: Revolutionizing Waste Management with Advanced Technology

Title: Revolutionary Bottle Crusher Machine Transforms Recycling IndustryIntroduction (approximately 100 words):In an era where sustainability and environmental responsibility are more crucial than ever, ABC Company is leading the way with their revolutionary Bottle Crusher Machine. The cutting-edge technology behind this innovative solution is set to transform the recycling industry by streamlining the process of plastic bottle disposal. By eliminating the need for manual sorting and reducing the volume of bottles considerably, this machine is set to greatly enhance recycling efforts and decrease the carbon footprint associated with plastic waste.Body:1. Overcoming Recycling Challenges (approximately 200 words):The Bottle Crusher Machine by ABC Company is designed to tackle the challenges that traditional recycling methods face head-on. Manual sorting of plastic bottles is a labor-intensive and time-consuming process, often leading to inefficiencies and increased costs. Moreover, large volumes of bottles fill up landfill sites rapidly, causing environmental concerns. To tackle these challenges, ABC Company has developed a state-of-the-art solution. By employing advanced technology such as artificial intelligence and machine learning algorithms, the Bottle Crusher Machine can quickly and accurately sort different types of plastic bottles, significantly reducing manual labor and increasing operational efficiency.2. Key Features and Functionality (approximately 200 words):The Bottle Crusher Machine incorporates several key features that set it apart from traditional recycling methods. One such feature is its ability to automatically crush and compact plastic bottles of various shapes and sizes. This process ultimately results in reduced storage requirements, enabling recycling centers to maximize their available space.Moreover, the machine is equipped with advanced sensors and algorithms that enable it to differentiate between different types of plastic bottles. By sorting these bottles based on their composition, the machine ensures that they are sent for appropriate recycling or disposal processes. This innovative functionality helps significantly reduce contamination in recycling streams, resulting in higher-quality recycled materials.3. Positive Environmental Impact (approximately 200 words):The Bottle Crusher Machine's introduction is expected to have a significant positive impact on reducing plastic waste and promoting sustainable practices. With the ability to compact bottles, the machine helps minimize the amount of space required for storage and transportation of plastic waste. This ultimately reduces the carbon footprint associated with plastic disposal.In addition, by streamlining the recycling process and enhancing efficiency, the machine encourages more people to recycle their plastic bottles. With increased convenience and reduced effort required on the part of consumers, the rate of recycling is likely to rise considerably. This, in turn, will lead to a decreased reliance on landfill sites, thereby preserving natural resources and mitigating the adverse effects of plastic waste on the environment.Conclusion (approximately 100 words):The introduction of ABC Company's Bottle Crusher Machine marks a significant step forward in revolutionizing the recycling industry. By combining cutting-edge technology, efficient sorting algorithms, and a commitment to sustainability, this machine is set to transform plastic bottle disposal. With the potential to increase recycling rates, reduce contamination, and streamline operations, this revolutionary device paves the way for a more sustainable future. ABC Company's continued dedication to driving positive environmental change positions them at the forefront of the recycling industry, working towards a cleaner and greener planet.

Efficient and Precise Cutting Machine for UPVC Profiles

The leading manufacturer of uPVC profile cutting machines, a company known for its innovative and reliable products, has recently introduced a new machine that is set to revolutionize the production process for uPVC profiles. This cutting-edge machine is designed to optimize efficiency and precision in cutting uPVC profiles, making it an essential tool for manufacturers in the uPVC industry.The new uPVC profile cutting machine is equipped with state-of-the-art technology that allows for seamless and accurate cutting of uPVC profiles. Its advanced features include a high-speed cutting mechanism, a multi-axis control system, and automated positioning for precise cutting. This machine is also designed to handle various types of uPVC profiles, ensuring versatility and flexibility for manufacturers.With the introduction of this new machine, the company aims to address the challenges faced by uPVC profile manufacturers in the production process. By providing a solution that offers superior precision and efficiency, the company is committed to helping manufacturers streamline their operations and enhance the quality of their uPVC profiles.In addition to its advanced technology, the uPVC profile cutting machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and user-friendly controls ensure that operators can easily program and operate the machine, minimizing the need for extensive training and expertise.Furthermore, the machine is also equipped with safety features to ensure the well-being of operators and workers in the production facility. With built-in safety mechanisms and protective measures, the machine prioritizes the safety of its users while delivering exceptional cutting performance.The introduction of this new uPVC profile cutting machine reinforces the company's commitment to innovation and excellence in the uPVC industry. By continuously investing in research and development, the company remains at the forefront of technological advancements, ensuring that its products meet the evolving needs of manufacturers in the uPVC sector.Moreover, the company's dedication to quality and reliability is reflected in the superior performance of its uPVC profile cutting machines. With a proven track record of delivering high-quality products, the company has established itself as a trusted partner for uPVC profile manufacturers worldwide.As a leading manufacturer of uPVC profile cutting machines, the company has a strong global presence, with a network of distributors and service centers in key markets around the world. Its commitment to customer satisfaction and after-sales support ensures that manufacturers can rely on the company for comprehensive assistance and technical expertise.In conclusion, the introduction of the new uPVC profile cutting machine represents a significant milestone for the company and the uPVC industry as a whole. By providing manufacturers with a cutting-edge solution that enhances efficiency, precision, and versatility, the company continues to drive innovation and progress in the uPVC sector. As uPVC profile manufacturers seek to optimize their production processes and maintain a competitive edge in the market, this new machine offers a compelling solution that aligns with the industry's evolving needs. With its advanced technology, user-friendly features, and commitment to quality, the company's uPVC profile cutting machine sets a new standard for excellence in the industry.

Corrugated Pipe Extrusion Line: Advancements in Manufacturing Technology

Title: Leading Corrugated Pipe Extrusion Line Sets New Benchmark in the Plastic IndustryIntroduction (100 words):In an era of rapidly evolving technological advancements, {} has emerged as a frontrunner in the plastic extrusion industry. By offering state-of-the-art corrugated pipe extrusion lines, the company has revolutionized the production of high-quality plastic piping solutions worldwide. This breakthrough technology has not only streamlined manufacturing processes but also elevated the standards of durability and performance in the construction, agriculture, and infrastructure sectors. {} continues to lead the way by introducing cutting-edge machinery, underscoring its commitment to innovation, sustainability, and customer satisfaction.Paragraph 1 (100 words):With its unwavering dedication to precision engineering, {} has disrupted the domain of plastic extrusion lines. Designed and manufactured using cutting-edge technology, their corrugated pipe extrusion lines offer unmatched productivity, reliability, and flexibility. These advanced extrusion lines can efficiently produce a wide range of corrugated plastic pipes, catering to diverse industry requirements. Equipped with state-of-the-art control systems, these tailor-made extrusion lines enable manufacturers to produce high-quality pipes with consistency, meeting stringent industry regulations and customer demands.Paragraph 2 (150 words):Due to the inherent advantages of corrugated plastic pipes over conventional alternatives, such as PVC, steel, or concrete, the demand for this innovative solution has witnessed a substantial upsurge in recent years. By leveraging their expertise and extensive research, {} has developed a corrugated pipe extrusion line that can tackle the challenges associated with diverse applications, weather conditions, and external loading, ensuring unparalleled durability and longevity. This breakthrough technology allows for the production of pipes that exhibit excellent resistance to corrosion, chemical substances, and abrasion, making them ideal for applications in drainage systems, underground conduits, telecom networks, electrical systems, and agricultural irrigation.Paragraph 3 (200 words):The corrugated pipe extrusion lines by {} have set new benchmarks in terms of sustainability and resource efficiency. These extrusion lines utilize eco-friendly materials and incorporate energy-saving features to minimize carbon footprint and operational costs. By employing cutting-edge co-extrusion technology, {} ensures that the corrugated pipes produced are not only structurally robust but also offer superior hydraulic efficiency, reducing energy consumption during fluid transfer and providing significant cost savings to end-users.In addition to environmental benefits, {} also prioritizes safety and ease of operation. These extrusion lines are equipped with intelligent control systems that facilitate real-time monitoring and adjustment of critical parameters, ensuring optimal operational performance and reliability. The user-friendly interfaces enable operators to seamlessly navigate through complex extrusion processes, guaranteeing consistency and quality in the final product.In conclusion (100 words):With its innovative corrugated pipe extrusion lines, {} has established itself as a market leader, pushing the boundaries of plastic extrusion technology. By combining precision engineering, sustainability, and customer-centric design, the company has provided manufacturers with a reliable and efficient solution for producing high-quality corrugated plastic pipes. Through continued research and development, {} is constantly advancing its extrusion line technology, setting new industry standards, and powering the growth of various sectors including construction, agriculture, and infrastructure. Industry insiders predict that the company's commitment to innovation and sustainability will continue to shape the future of plastic extrusion technology worldwide.

The Undisclosed Expenses Associated with Twin Screw Extruder Acquisition

Title: Affordable Twin Screw Extruder Solutions Revolutionize the Manufacturing IndustryIntroduction:In today's competitive manufacturing landscape, companies across various industries are constantly exploring cost-effective solutions to enhance their production processes. One such solution gaining increasing popularity is the Twin Screw Extruder. With its ability to efficiently process a wide range of materials, this machinery is enabling businesses to achieve higher productivity and quality standards while streamlining expenses. This article delves into the innovation behind Twin Screw Extruders and the significant cost reductions they offer, making them an indispensable asset for manufacturers worldwide.1. The Twin Screw Extruder Advantage:Twin Screw Extruders are versatile machines used in various industries, including plastics, food processing, pharmaceuticals, and chemical manufacturing. These extruders consist of two intermeshing screws that operate side by side within a barrel. When the material enters the extruder, the rotating screws move it forward, subjecting it to mechanical and thermal forces that facilitate mixing, melting, and homogenizing.The twin screw configuration offers many advantages over single screw extruders, including higher throughput rates, improved mixing capabilities, and enhanced control over material properties. This versatility allows manufacturers to work with a broader range of materials, opening up new possibilities for product development.2. New Cost-Effective Solutions:Traditionally, accessing Twin Screw Extruders came with a hefty price tag, often limiting their widespread adoption among small and medium enterprises. However, recent technological advancements and market competition have resulted in more affordable, yet equally efficient, alternatives.Thanks to innovative engineering and streamlined manufacturing processes, several companies, including industry leaders and newer entrants, are offering cost-effective Twin Screw Extruder solutions, efficiently meeting the needs of manufacturers at a reduced investment. These affordable alternatives do not compromise on performance, reliability, or quality, allowing businesses of all sizes to leverage the benefits of this technology.3. Enhanced Performance and Efficiency:The incorporation of advanced technology in new-generation Twin Screw Extruders has significantly improved their performance and efficiency. These machines are engineered to handle a broader range of materials, including polymer blends, resins, and additives, with precision and consistency.The enhanced process control mechanisms, efficient energy consumption, and optimized screw design of these extruders ensure higher throughput rates and improved product quality. This results in reduced wastage, enhanced product consistency, and lower production costs for manufacturers. Additionally, the ability of Twin Screw Extruders to accommodate materials with a wide range of viscosities and melt temperatures further adds to their efficiency.4. Cost Reduction Strategies:The affordability of Twin Screw Extruders can be attributed to various factors. One such factor is the improved manufacturing process, where advancements in production techniques and standardized components have reduced both material and labor costs. Additionally, manufacturers are focused on simplifying maintenance routines, thereby reducing operational expenses over the machine's lifetime.Moreover, increased market competition has prompted suppliers to offer more cost-friendly alternatives without compromising on quality. This intense competition has driven innovation and rethinking of traditional design practices, leading to more streamlined, efficient, and reasonably priced Twin Screw Extruder models.5. Impact on Industries:The broader accessibility to affordable Twin Screw Extruders is revolutionizing several industries, allowing manufacturers to enhance their processes, develop new products, and stay competitive in the market. With reduced investment costs, more companies can now embrace these extruders to meet growing consumer demands and market challenges.The plastics industry, for instance, benefits from the twin screw technology by efficiently processing a wide range of polymers, resulting in high-quality and consistent end products. Similarly, in food processing, the extruders' ability to blend, cook, and shape ingredients enables manufacturers to create a vast array of products, from breakfast cereals to functional snacks.Conclusion:The availability of affordable Twin Screw Extruders is transforming the manufacturing industry by enabling businesses of all sizes to streamline their processes and enhance productivity. With improved performance, efficiency, and reduced investment costs, these extruders are becoming an indispensable asset for manufacturers worldwide. As competition continues to spur innovation in this field, the future holds promising advancements in Twin Screw Extruder technology, paving the way for further cost efficiencies and enhanced manufacturing capabilities.