High-quality Screw Extruder for Efficient Manufacturing

By:Admin

In recent years, the manufacturing industry has been witnessing a significant technological revolution, and one of the key players in this transformation is the screw extruder technology. This innovative technology has proven to be a game-changer in various manufacturing processes, offering increased efficiency, precision, and versatility. As companies strive to stay ahead in the competitive market, the adoption of screw extruder technology has become essential for enhancing productivity and maintaining high-quality production standards.

One of the leading pioneers in the development and application of screw extruder technology is [Company Name]. With a rich history of innovation and a strong commitment to pushing the boundaries of manufacturing technology, [Company Name] has established itself as a trusted name in the industry. The company's expertise in screw extruder technology has enabled it to offer cutting-edge solutions to a wide range of manufacturing processes, from plastic extrusion to food processing and pharmaceutical manufacturing.

At the core of [Company Name]'s screw extruder technology is its state-of-the-art research and development facilities, which are equipped with the latest machinery and a team of highly skilled engineers and scientists. This allows the company to continuously improve and refine its screw extruder technology, ensuring that it remains at the forefront of the industry. Additionally, [Company Name] places a strong emphasis on collaborating with its customers to understand their unique needs and challenges, providing customized solutions that deliver maximum impact and value.

One of the key benefits of screw extruder technology is its ability to precisely control the flow and mixing of materials, resulting in superior product quality and consistency. By leveraging advanced automation and control systems, [Company Name] has been able to optimize the performance of its screw extruders, enabling manufacturers to achieve a higher level of precision and efficiency in their production processes. This has proven to be especially valuable in industries such as plastics and rubber, where the demand for high-quality products is constantly increasing.

Furthermore, screw extruder technology offers a high degree of versatility, allowing manufacturers to adapt to changing market demands and produce a wide range of products with minimal retooling. This flexibility has been a major driving force behind the adoption of screw extruders in various industries, as it enables companies to streamline their production processes and respond quickly to new market opportunities. In this regard, [Company Name] has been instrumental in providing innovative solutions that empower manufacturers to stay agile and adaptive in today's dynamic business environment.

Another notable feature of [Company Name]'s screw extruder technology is its focus on sustainability and energy efficiency. The company has developed cutting-edge designs and materials that minimize waste and reduce energy consumption, aligning with the global push towards sustainable manufacturing practices. By integrating these eco-friendly solutions into its screw extruder technology, [Company Name] has helped its customers lower their environmental impact while enhancing their operational performance.

Looking to the future, [Company Name] remains committed to pushing the boundaries of screw extruder technology, with ongoing investments in research and development to drive continuous innovation. The company is also actively exploring new applications and markets for its screw extruder technology, seeking to unlock new opportunities for its customers and further expand its impact on the manufacturing industry.

In conclusion, screw extruder technology has emerged as a key enabler for driving efficiency, precision, and adaptability in the manufacturing industry, and [Company Name] stands at the forefront of this revolution. With its relentless pursuit of innovation and its commitment to meeting the evolving needs of the market, [Company Name] has cemented its position as a trusted partner for manufacturers seeking to elevate their production processes with advanced screw extruder technology. As the industry continues to evolve, [Company Name] is poised to lead the way in shaping the future of manufacturing with its cutting-edge solutions.

Company News & Blog

Efficient and Reliable PVC Pipe Making Machine Unveiled, Promising Sturdy Manufacturing Results

Title: Innovative Rigid PVC Pipe Making Machine Revolutionizes Manufacturing ProcessIntroduction:In today's ever-evolving industrial landscape, innovation plays a crucial role in boosting productivity and efficiency. Breaking barriers with its groundbreaking technology, the Rigid PVC Pipe Making Machine (brand name removed) is set to revolutionize the manufacturing process, making it faster, more reliable, and cost-effective. This cutting-edge machine, developed by a leading company in the field, incorporates advanced features designed to meet the demands of the PVC pipe industry. In this article, we will delve into the innovative aspects of this machine, highlighting its potential impact on the manufacturing sector.1. Precision and Efficiency:The Rigid PVC Pipe Making Machine represents a significant step forward in the quest for precision and efficiency in industrial processes. This state-of-the-art machine integrates advanced components and modern technologies, enabling it to provide accurate and consistent results. The precise control system allows for greater control over key parameters such as temperature, pressure, and speed, ensuring the production of high-quality pipes with minimal material wastage. Moreover, the machine's automated procedures reduce manpower requirements, thereby boosting overall efficiency and cost-effectiveness.2. Versatility and Adaptability:The Rigid PVC Pipe Making Machine offers remarkable versatility and adaptability, making it suitable for a wide range of pipe production requirements. The machine is designed to accommodate various pipe diameters and thicknesses, making it an ideal choice for both small-scale and large-scale PVC pipe manufacturers. The flexibility provided by this machine allows manufacturers to produce an array of pipes to cater to diverse industry needs, whether for irrigation, plumbing, or industrial applications. Its ability to accommodate different pipe specifications allows for increased customization, meeting the unique demands of customers.3. Energy Efficiency and Environmental Consciousness:Acknowledging the importance of sustainable practices in today's world, the Rigid PVC Pipe Making Machine integrates energy-efficient features that contribute to reduced energy consumption, thereby minimizing the carbon footprint of the manufacturing process. Advanced insulation technology ensures minimal energy loss, optimizing thermal efficiency. Additionally, the machine incorporates modern filtration systems that effectively remove impurities and minimize waste generation, promoting environmental consciousness and sustainability. This eco-friendly approach aligns with global efforts to adopt greener manufacturing practices.4. Streamlined Operation and Maintenance:Ease of operation and maintenance are crucial factors in modern machinery, and the Rigid PVC Pipe Making Machine excels in both areas. Its user-friendly interface and intuitive controls simplify machine operation, reducing the learning curve for operators. Additionally, the machine's self-diagnostic capabilities enable early detection of potential issues, minimizing downtime and ensuring uninterrupted production. Regular maintenance requirements are simplified with accessible components and a robust design, reducing maintenance costs and increasing overall equipment lifespan.Conclusion:The introduction of the Rigid PVC Pipe Making Machine highlights the continuous progress being made in the manufacturing sector. By combining precision, versatility, energy efficiency, and streamlined operation, this innovative machine sets a new standard for the production of PVC pipes. Its ability to meet the diverse demands of the industry while delivering high-quality results showcases its potential to revolutionize the manufacturing process. As industries strive for enhanced productivity and sustainability, the Rigid PVC Pipe Making Machine emerges as a game-changer in the industry, paving the way for a more efficient and eco-conscious manufacturing landscape.

Industrial Plastic Mixer Machine: A Key Component for Manufacturing Processes

Introducing a Revolutionary Plastic Mixer Machine: A Game Changer for the Plastics IndustryThe plastics industry has seen significant advancements in technology and machinery in recent years, and one company is leading the way with its state-of-the-art plastic mixer machine. With a strong focus on innovation and sustainability, {} has developed a revolutionary mixer machine that is set to transform the way plastics are processed and manufactured.The new plastic mixer machine, which will be unveiled at an industry trade show next month, is a game changer for the plastics industry. It is designed to significantly improve the efficiency and quality of plastic mixing processes, making it a must-have for plastic manufacturers and processors around the world.The plastic mixer machine is equipped with advanced technology that allows for precise and uniform mixing of various types of plastics, including PVC, PET, and polyethylene. This level of precision and control is essential for ensuring the quality and consistency of plastic materials, which is crucial for producing high-quality end products.In addition to its advanced mixing capabilities, the new plastic mixer machine also features a number of sustainability-focused innovations. It is designed to minimize energy consumption and reduce waste, making it a more environmentally friendly option for plastic processing. This aligns with {}'s commitment to sustainable and responsible manufacturing practices.The company's dedication to innovation and sustainability is deeply rooted in its history. {} has been at the forefront of the plastics industry for over 30 years, consistently pushing the boundaries of what is possible in plastic manufacturing. With a team of experienced engineers and a dedication to continuous improvement, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the industry.The introduction of the new plastic mixer machine is a testament to {}'s ongoing commitment to innovation and excellence. By developing a machine that offers unparalleled precision, efficiency, and sustainability, the company is once again raising the bar for the plastics industry."We are excited to introduce our revolutionary plastic mixer machine to the market," said {}'s CEO. "This machine is the result of years of hard work and dedication from our team, and we believe it will have a significant impact on the industry. We are confident that it will set a new standard for plastic mixing processes and help our customers achieve new levels of efficiency and quality in their operations."The plastic mixer machine is set to be officially launched at the upcoming trade show, where attendees will have the opportunity to see it in action and learn more about its capabilities. The company is already receiving significant interest and inquiries from potential customers who are eager to incorporate the new machine into their operations.As the plastics industry continues to evolve, innovative solutions like {}'s plastic mixer machine will be essential for driving progress and meeting the changing needs of manufacturers and processors. With its advanced technology, sustainability focus, and track record of excellence, {} is well-positioned to lead the way in this next phase of the industry's development.In conclusion, the introduction of the new plastic mixer machine from {} represents a significant milestone for the plastics industry. With its advanced technology and sustainability-focused design, the machine is poised to revolutionize plastic mixing processes and set a new standard for efficiency and quality. As {} continues to push the boundaries of what is possible in plastic manufacturing, the industry can expect to see even more innovative solutions that address the evolving needs of manufacturers and processors.

Efficient Plastic Recycling Granulator for Sustainable Waste Management

A leading manufacturer in the industry of plastic recycling equipment, has recently introduced a new Plastic Recycling Granulator that aims to revolutionize the process of recycling and reprocessing plastic waste. This innovative machine is designed to meet the growing demand for sustainable and efficient solutions in the recycling industry.The Plastic Recycling Granulator incorporates state-of-the-art technology and advanced features that enable it to process a wide range of plastic materials, including HDPE, LDPE, PP, PVC, and PET. It is capable of granulating plastic waste into high-quality granules that can be used in the production of various plastic products, thus contributing to the circular economy and reducing the environmental impact of plastic waste.One of the key features of this new Plastic Recycling Granulator is its high efficiency and productivity. With a powerful motor and a robust cutting system, it is able to process large volumes of plastic waste in a short period of time, making it an ideal solution for recycling facilities and plastic manufacturers. In addition, it is equipped with advanced sensing and control systems that ensure consistent and precise granule size, resulting in superior quality output.Moreover, the Plastic Recycling Granulator is designed with user-friendly controls and easy maintenance features, making it convenient and cost-effective for operators to use and maintain. It also comes with built-in safety measures to ensure the protection of operators and prevent accidents in the workplace.In line with the company's commitment to sustainability, this new Plastic Recycling Granulator is also designed to minimize energy consumption and reduce operational costs. By optimizing the granulation process and utilizing energy-efficient components, it helps recycling facilities to lower their carbon footprint and achieve higher profitability.The introduction of this new Plastic Recycling Granulator is a testament to the company's dedication to innovation and continuous improvement. With decades of experience in the industry, they have a proven track record of delivering reliable, high-performance recycling equipment that meets the evolving needs of the market.Furthermore, the company boasts a team of highly skilled engineers and technicians who are dedicated to providing technical support and expertise to customers. This ensures that customers receive comprehensive assistance in the installation, operation, and maintenance of their recycling equipment, thus maximizing the performance and longevity of their investment.In addition to manufacturing and distributing plastic recycling equipment, the company also offers a range of consulting services to support customers in optimizing their recycling processes and maximizing their return on investment. This holistic approach demonstrates their ongoing commitment to supporting the success of their customers in the plastic recycling industry.In conclusion, the introduction of the new Plastic Recycling Granulator by demonstrates the company's dedication to driving positive change in the recycling industry. With its advanced capabilities, efficiency, and sustainability features, this new machine is set to make a significant impact on the way plastic waste is managed and reprocessed. As the demand for sustainable solutions continues to grow, this innovative recycling equipment is poised to play a pivotal role in advancing the circular economy and reducing the environmental footprint of plastic waste.

Efficient and Eco-Friendly Pet Flakes Washing Machine for Recycling Industry

Pet Flakes Washing Machine, an innovative solution to plastic waste management, is a revolutionary step towards a sustainable future. This advanced machine is designed to effectively clean and recycle PET (Polyethylene Terephthalate) flakes, thereby contributing to the reduction of plastic pollution. The company, a leading manufacturer of industrial machinery, is dedicated to providing cutting-edge technology for environmental conservation and sustainable development.With the increasing global concern over plastic waste, the demand for efficient recycling solutions has never been greater. The Pet Flakes Washing Machine addresses this pressing issue by offering an efficient and cost-effective method for cleaning and processing PET flakes. This not only helps in reducing the environmental impact of plastic waste but also contributes to the circular economy by promoting the reuse of materials.The machine is equipped with advanced washing and drying equipment, which ensures that the PET flakes are thoroughly cleaned and prepared for further processing. Its efficient filtration and separation system effectively removes contaminants and impurities, resulting in high-quality recycled PET flakes. The entire process is automated, ensuring consistency and reliability in the output.In addition to its technological prowess, the company behind the Pet Flakes Washing Machine is committed to sustainability and environmental responsibility. Their dedication to research and development has led to the creation of a machine that not only meets industry standards but also prioritizes energy efficiency and resource conservation. By utilizing this machine, businesses can not only contribute to the reduction of plastic waste but also improve their overall environmental footprint.The company's approach to sustainability extends beyond just the design of the machine. They also offer comprehensive support and training for their clients, empowering them to effectively operate and maintain the equipment. This commitment to customer satisfaction ensures that businesses can seamlessly integrate the Pet Flakes Washing Machine into their operations, further promoting sustainable practices within the industry.Furthermore, the company's focus on innovation and continuous improvement sets them apart in the market. They constantly strive to enhance their products and services, staying at the forefront of technological advancements in the field of plastic recycling. This dedication to excellence positions them as a reliable and forward-thinking partner for businesses seeking to invest in sustainable solutions.The Pet Flakes Washing Machine is not just a piece of equipment; it represents a significant step towards a cleaner and greener future. By offering a viable and efficient solution for PET flake recycling, the company is contributing to the global efforts to mitigate the environmental impact of plastic waste. With their commitment to sustainability, innovation, and customer satisfaction, they are poised to make a lasting impact on the industry and the planet.As the world continues to grapple with the challenges posed by plastic waste, the introduction of the Pet Flakes Washing Machine brings a ray of hope. It showcases the potential for technology to drive positive change and offers a tangible solution for businesses looking to embrace sustainability. With the support and expertise of the company behind this groundbreaking innovation, the adoption of this technology is set to make a meaningful difference in the fight against plastic pollution.

Revolutionizing Plastic Recycling: Discover the Innovative Shredder Recycling Plant

[News Title][City, Date] - In an effort to combat the growing problem of plastic waste and promote a sustainable future, a leading recycling company has recently unveiled its state-of-the-art plastic shredder recycling plant. The plant, which is capable of handling large quantities of plastic waste, is set to revolutionize the recycling industry and make significant strides towards environmental conservation. [Company Name], a renowned player in the recycling sector, specializes in innovative and eco-friendly solutions for waste management. With the launch of their new plastic shredder recycling plant, the company aims to address the urgent need for effective plastic recycling methods. The plant, located in [City], is equipped with cutting-edge technology and machinery that can efficiently process various types of plastic waste. From plastic bottles and containers to packaging material, the plant is capable of shredding and transforming these items into reusable materials. This process significantly reduces the amount of plastic waste that ends up in landfills or natural habitats, safeguarding the environment for future generations. According to [Company Name] spokesperson, "Our plastic shredder recycling plant represents a significant step towards achieving a circular economy, where waste is reduced, reused, and recycled. By implementing state-of-the-art technologies, we can meet the increasing demand for plastic recycling while minimizing environmental impact."The plant operates through a systematic process that ensures every piece of plastic waste is effectively shredded and sorted. Once the plastic waste is fed into the shredder, it is pulverized into smaller pieces, making it easier to handle in subsequent stages. Following this, the shredded plastic undergoes a meticulous separation process, dividing it into different types based on its composition and color. This division allows for more precise recycling methods, resulting in superior-quality recycled plastic materials.One of the key advantages of the plastic shredder recycling plant is its ability to handle a significant volume of plastic waste. Its high capacity ensures that large quantities of plastic can be processed efficiently, contributing to a more sustainable approach to waste management. The plant also boasts energy-saving features, equipped with advanced systems that minimize energy consumption while maximizing output.In addition to its environmental significance, the plant is expected to create numerous job opportunities for local communities. The establishment of the plant has resulted in additional employment opportunities, from plant operators and maintenance personnel to logistics and administrative staff. This development not only benefits the environment but also bolsters the local economy by promoting growth and providing sustainable livelihoods.The plastic shredder recycling plant represents a pivotal step towards tackling the global plastic waste crisis. By implementing advanced technologies and innovative recycling methods, [Company Name] is taking a crucial role in reducing the environmental impact of plastic waste. The plant's high capacity, precise separation techniques, and energy-saving features make it a game-changer in the recycling industry.As plastic pollution continues to pose a significant threat to our environment, it is imperative for companies like [Company Name] to lead the way in sustainable waste management. The plastic shredder recycling plant not only showcases their commitment to the environment but also sets a remarkable example for others in the industry to follow.With initiatives like this, it is hoped that the world will witness a paradigm shift in plastic waste management, embracing a circular economy where plastic products are recycled and given a second life. Through collaborative efforts and groundbreaking technologies, we can work towards a cleaner, greener future for generations to come.

How Plastic Pipe Extruders are Shaping the Manufacturing Industry

Plastic Pipe Extruder Unveils Groundbreaking Innovation in Pipeline TechnologyThe plastic pipe extrusion industry is rapidly evolving, and leading the way in this technological revolution is [Company Name], a global leader in the manufacturing of high-quality plastic pipe products. With a commitment to innovation and sustainability, [Company Name] has recently unveiled their latest groundbreaking innovation in pipeline technology that is set to revolutionize the industry.The newly developed product, which leverages state-of-the-art extrusion technology, promises to deliver unparalleled performance and durability, while also addressing the growing concerns for environmental sustainability. Unlike traditional metal pipes, the plastic pipes produced by [Company Name] are lightweight, corrosion-resistant, and highly cost-effective, making them an ideal solution for a wide range of applications, including water distribution, sewer systems, and industrial piping.[Company Name] has long been recognized for its expertise in plastic pipe extrusion, boasting a rich history of innovation and a proven track record of delivering superior products to a global customer base. With a dedicated team of research and development experts, the company has continually pushed the boundaries of what is possible in the world of plastic pipe manufacturing.In addition to their commitment to technological advancement, [Company Name] also places a strong emphasis on sustainability and environmental responsibility. The newly developed plastic pipes are made from high-quality, recyclable materials, ensuring that the environmental impact of their production and usage is minimized. This aligns with the company's broader mission to promote a more sustainable and eco-friendly approach to pipeline infrastructure.Furthermore, [Company Name] has implemented stringent quality control measures throughout the production process, ensuring that each plastic pipe that rolls off their assembly line meets the highest standards of excellence. This dedication to quality has earned the company a sterling reputation within the industry, with customers around the world trusting [Company Name] to provide reliable and long-lasting pipeline solutions.With the unveiling of their latest innovation, [Company Name] is poised to reinforce its position as an industry leader in plastic pipe extrusion. The new product is expected to set a new benchmark for performance and reliability, offering customers a cutting-edge solution that meets the demands of modern infrastructure projects.Commenting on the launch of the new product, [Company Name]'s CEO expressed his confidence in the capabilities of the innovative plastic pipe extrusion technology, stating, "We are proud to introduce this groundbreaking innovation to the market. Our team has worked tirelessly to develop a product that not only outperforms traditional pipeline materials but also aligns with our commitment to sustainability. We believe that this innovation will have a transformative impact on the industry, and we are excited to see the positive outcomes it will bring to our customers and the environment."As the global demand for high-quality, sustainable pipeline solutions continues to grow, [Company Name] is well-positioned to meet the evolving needs of the market. Their dedication to innovation, quality, and environmental responsibility sets them apart as a leading force in the plastic pipe extrusion industry, and their latest breakthrough is a testament to their ongoing pursuit of excellence.In conclusion, the unveiling of [Company Name]'s groundbreaking innovation in pipeline technology represents a significant milestone in the evolution of the plastic pipe extrusion industry. Through their commitment to innovation, sustainability, and quality, [Company Name] continues to lead the way in providing cutting-edge solutions for infrastructure projects around the world. With their latest product set to redefine the standards for pipeline performance and durability, [Company Name] is undeniably shaping the future of the industry.

High Quality PVC Pipe Extrusion Machine for Sale - Find the Best Deal Today!

Pvc Pipe Extrusion Machine For SaleAt present, the demand for PVC pipes has increased significantly in the construction and infrastructure sectors due to their durability, low cost, and effectiveness in transporting fluids and chemicals. As a result, the demand for PVC pipe extrusion machines has also surged, as manufacturers seek to meet the growing market needs. In response to this demand, a leading machinery manufacturing company has announced the availability of its high-quality PVC pipe extrusion machine for sale.The {Company Name} is renowned for its expertise in designing and manufacturing innovative machinery for the plastic processing industry. With a focus on delivering precision, efficiency, and reliability, the company has become a trusted partner for businesses seeking cost-effective and high-performance solutions for PVC pipe production. The newly available PVC pipe extrusion machine is a testament to the company's commitment to providing advanced technology to enhance the productivity and quality of plastic pipe manufacturing.This state-of-the-art PVC pipe extrusion machine is equipped with advanced features and capabilities to meet the evolving needs of the plastic processing industry. It is designed to optimize the production process by ensuring consistent output, precise dimensions, and high structural integrity of the PVC pipes. The machine is capable of handling a wide range of PVC raw materials, making it versatile and adaptable to various production requirements.The extrusion process is at the core of PVC pipe manufacturing, and the {Company Name} has integrated cutting-edge technology into its machine to ensure superior performance. The machine's extrusion system is engineered to deliver high output rates while maintaining energy efficiency, resulting in cost-effective production for manufacturers. Additionally, the machine's control systems are designed for user-friendly operation, enabling operators to monitor and adjust production parameters with ease.Furthermore, the {Company Name} takes pride in its commitment to quality and durability, reflected in the construction of the PVC pipe extrusion machine. By utilizing premium materials and robust engineering, the machine is built to withstand the rigors of continuous production, ensuring longevity and minimal downtime for manufacturers. This reliability is paramount for businesses seeking a dependable solution for their PVC pipe manufacturing operations.In addition to the machine's technical capabilities, the {Company Name} also provides comprehensive support and service to its customers. From installation and training to maintenance and technical assistance, the company's team of experts is dedicated to ensuring that customers derive maximum value from their investment in the PVC pipe extrusion machine. This commitment to customer satisfaction has earned the {Company Name} a reputation for excellence in the plastic processing industry.As the demand for PVC pipes continues to grow, the availability of high-quality PVC pipe extrusion machines becomes increasingly crucial for manufacturers striving to meet market requirements. With its latest offering, the {Company Name} reaffirms its position as a leading provider of advanced machinery for the plastic processing industry. The PVC pipe extrusion machine for sale represents an opportunity for businesses to enhance their production capabilities and capitalize on the growing demand for PVC pipes.In conclusion, the {Company Name}'s PVC pipe extrusion machine for sale is a testament to the company's dedication to innovation, quality, and customer satisfaction. With its advanced features, robust construction, and comprehensive support, the machine serves as an ideal solution for manufacturers seeking to upscale their PVC pipe production. As the industry continues to evolve, the {Company Name} remains at the forefront, delivering cutting-edge technology to empower businesses in the plastic processing sector.

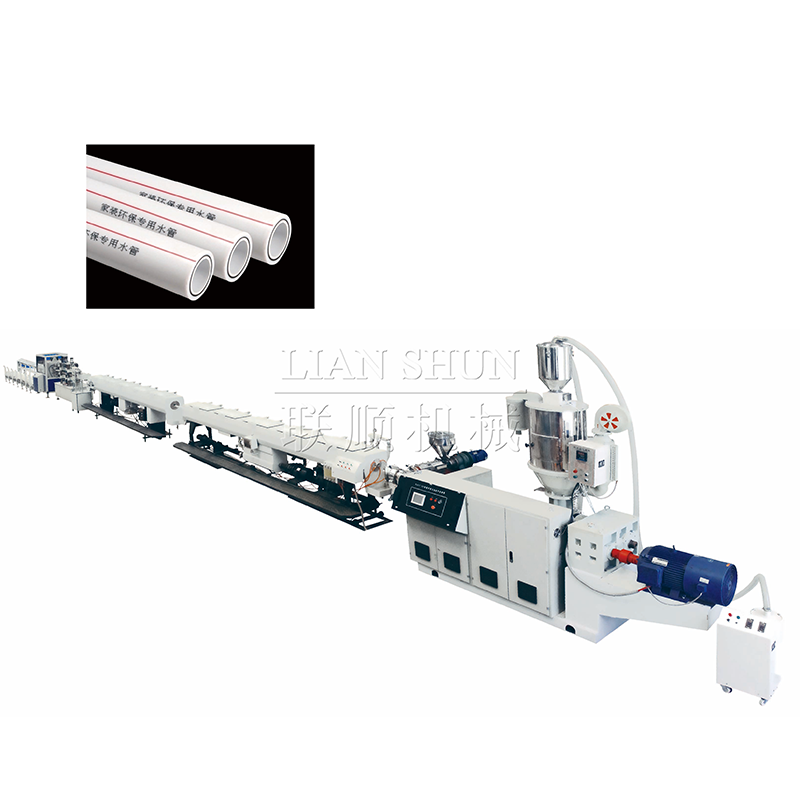

High-Quality PPR Pipe Machine for Efficient Pipe Production

Ppr Pipe Machine is a leading company in the field of plastic extrusion technology, specializing in the manufacturing of high-quality PPR pipe machines. The company has been at the forefront of the plastic extrusion industry for over 20 years and has earned a reputation for producing top-of-the-line machinery that meets the highest standards of quality and performance.With the increasing demand for PPR pipes in various industries, the need for advanced and efficient PPR pipe machines has also risen. In response to this demand, Ppr Pipe Machine has been continuously investing in research and development to innovate and improve their product line. The company is dedicated to providing innovative solutions to meet the evolving needs of the plastic extrusion industry.One of the key features of Ppr Pipe Machine's products is their advanced technology and precision engineering. The company uses state-of-the-art machinery and equipment to ensure that their PPR pipe machines are capable of delivering high productivity, excellent performance, and exceptional quality. The machines are designed to be user-friendly, efficient, and cost-effective, thus providing customers with a competitive edge in the market.Ppr Pipe Machine's commitment to quality is evident in their strict adherence to international standards and certifications. The company's machines are compliant with ISO 9001:2015, CE, and other relevant certifications, which attest to their commitment to delivering superior quality products. This dedication to quality has earned Ppr Pipe Machine the trust and loyalty of customers worldwide.Furthermore, Ppr Pipe Machine takes pride in its excellent customer service and technical support. The company has a team of highly skilled and experienced engineers who provide comprehensive support to customers, from the initial inquiry stage to after-sales service. This ensures that customers receive the necessary assistance and guidance to make the most out of their investment in PPR pipe machines.In line with their commitment to sustainability, Ppr Pipe Machine also places a strong emphasis on environmental responsibility. The company's manufacturing processes prioritize energy efficiency and waste reduction, in addition to ensuring that their products comply with environmental regulations. Ppr Pipe Machine is dedicated to minimizing its environmental impact and contributing to a more sustainable future.In addition to their dedication to quality and innovation, Ppr Pipe Machine also values collaboration and partnerships within the industry. The company works closely with suppliers, distributors, and other stakeholders to foster strong relationships and achieve mutual success. Ppr Pipe Machine is committed to delivering value to its partners and customers, thus strengthening its position as a reliable and trusted supplier in the plastic extrusion industry.Looking ahead, Ppr Pipe Machine remains focused on continuous improvement and advancement in their product line. The company is dedicated to staying at the forefront of technological developments in the plastic extrusion industry and providing customers with cutting-edge solutions for their PPR pipe production needs. Ppr Pipe Machine is poised to continue its legacy of excellence and innovation, driving the industry forward with its superior quality PPR pipe machines.In conclusion, Ppr Pipe Machine is a leading company in the plastic extrusion industry, known for its commitment to quality, innovation, and customer satisfaction. With a strong emphasis on advanced technology, precision engineering, and environmental responsibility, Ppr Pipe Machine continues to set the bar high for the manufacturing of PPR pipe machines. As the demand for PPR pipes continues to grow, Ppr Pipe Machine is well-equipped to meet the evolving needs of the industry and provide customers with top-of-the-line solutions.

Highly Efficient Pulverizer Machine for Plastic - A Complete Guide

Pulverizer Machine For Plastic - A Game Changer in Plastic RecyclingIn the wake of increasing concern over plastic pollution, the need for effective plastic recycling solutions has never been more urgent. In response to this global challenge, {Company Name} has taken a significant step forward with the introduction of their advanced Pulverizer Machine for plastic recycling.The {Company Name} is a leading manufacturer and supplier of industrial machinery and equipment, specializing in the development of innovative solutions for the recycling industry. With a strong commitment to sustainability and environmental responsibility, the company has positioned itself as a driving force in the quest for efficient and effective plastic recycling technologies.The Pulverizer Machine for plastic is a cutting-edge innovation that is set to revolutionize the way plastic waste is processed and recycled. Unlike traditional recycling methods that rely on mechanical shredding and grinding, this advanced machine utilizes a sophisticated pulverizing technique to break down plastic materials into fine particles. This not only allows for a more thorough and efficient recycling process but also produces a higher quality end product.One of the key features of the Pulverizer Machine is its versatility and adaptability. The machine is designed to handle a wide range of plastic materials, including PET, HDPE, PVC, and more. This flexibility makes it an ideal solution for recycling facilities and businesses that deal with various types of plastic waste.In addition to its exceptional performance, the Pulverizer Machine is also designed with user-friendly features that enhance its ease of operation and maintenance. This includes a user-friendly interface, automated controls, and a durable, low-maintenance design. As a result, operators can maximize productivity and efficiency while minimizing downtime and maintenance costs.The introduction of the Pulverizer Machine for plastic is a testament to {Company Name}'s ongoing commitment to innovation and sustainability. By providing the recycling industry with a state-of-the-art solution, the company is not only addressing the pressing issue of plastic waste but also empowering businesses and organizations to make a tangible impact on the environment.The benefits of the Pulverizer Machine extend beyond its environmental impact. By streamlining the plastic recycling process and producing high-quality recycled materials, the machine also offers significant economic advantages. Businesses and recycling facilities that implement this innovative technology can expect to see improvements in their operational efficiency, cost savings, and overall profitability.Furthermore, the Pulverizer Machine aligns with the growing global emphasis on circular economy principles, which prioritize the reduction, reuse, and recycling of materials. In doing so, {Company Name} is not only contributing to a more sustainable future but also positioning itself as a leader in the transition towards a more circular and resource-efficient economy.As the demand for effective plastic recycling solutions continues to rise, {Company Name} is poised to play a pivotal role in shaping the industry's future. With the Pulverizer Machine for plastic, the company has demonstrated its commitment to driving innovation, promoting sustainability, and empowering its customers to make a positive impact on the environment.In conclusion, the introduction of the Pulverizer Machine for plastic represents a significant milestone for {Company Name} and the plastic recycling industry as a whole. By leveraging cutting-edge technology and a strong sustainability focus, the company has pioneered a game-changing solution that is set to redefine the way plastic waste is processed and recycled. As the momentum for sustainable and responsible plastic recycling continues to grow, the Pulverizer Machine stands ready to lead the charge towards a more sustainable and circular future.

Complete Guide to WPC Extrusion Line: Equipment, Process, and Applications

In recent years, the demand for wood-plastic composite (WPC) products has been on the rise due to their various benefits such as durability, low maintenance, and eco-friendliness. To meet the growing market demand, a leading machinery manufacturer, has introduced a state-of-the-art WPC extrusion line that promises to revolutionize the production process of WPC products.This new WPC extrusion line is equipped with advanced technology and features that set it apart from traditional extrusion lines. It is designed to offer high efficiency, precision, and flexibility in the production of a wide range of WPC products, including decking, fencing, railing, and flooring. With its innovative design and high-quality components, this extrusion line is capable of producing WPC products with superior quality and performance.One of the key features of this WPC extrusion line is its modular design, which allows for easy customization and scalability according to the specific production requirements of the customers. This means that manufacturers can easily adapt the extrusion line to produce different types of WPC products without the need for significant retooling or downtime. This level of flexibility is essential in today's fast-paced market, where product innovation and differentiation are crucial for staying ahead of the competition.In addition to its flexibility, this WPC extrusion line also offers high efficiency and productivity. Its advanced control system and automation features ensure smooth and consistent production, resulting in minimal material waste and maximum output. This not only helps manufacturers reduce production costs but also ensures that they can meet the increasing demand for WPC products in a timely manner.Furthermore, the WPC extrusion line is designed with sustainability in mind. It is capable of using recycled materials and natural fibers as raw materials, making it an environmentally friendly choice for WPC production. This aligns with the growing consumer preference for sustainable and eco-friendly products, giving manufacturers a competitive edge in the market.Aside from the technological advancements, the company behind this WPC extrusion line also offers comprehensive customer support and service. With its extensive experience and expertise in the field of extrusion machinery, the company is well-equipped to provide technical assistance, training, and spare parts to ensure the smooth operation of the WPC extrusion line for its customers.It is worth mentioning that the company has a proven track record of delivering high-quality and reliable machinery to the WPC industry. With its dedication to innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for WPC manufacturers worldwide.Overall, the introduction of this advanced WPC extrusion line marks a significant milestone in the WPC industry. It not only represents a leap forward in terms of technology and production capabilities but also underscores the potential for further growth and innovation in the WPC market.In conclusion, the new WPC extrusion line from the company is set to reshape the landscape of WPC production with its cutting-edge technology, efficiency, flexibility, and sustainability. As the demand for WPC products continues to grow, this extrusion line is poised to play a pivotal role in meeting the market needs and driving the industry forward.