Top Plastic Granulators for Efficient Recycling and Grinding

By:Admin

In the fast-paced world of industrial manufacturing, the need for efficient and sustainable waste management solutions has never been greater. With the rise in global demand for plastic products, the volume of plastic waste generated has also skyrocketed, leading to a pressing need for effective recycling and processing technologies. This is where plastic granulators come into play.

{Company name} is a leading manufacturer of high-quality plastic granulators, offering a comprehensive range of machines designed to meet the diverse needs of the plastic recycling industry. With a strong commitment to innovation, reliability, and customer satisfaction, {Company name} has established itself as a trusted provider of cutting-edge granulation solutions.

Plastic granulators play a critical role in the recycling process, as they are designed to reduce plastic waste into smaller, uniform particles known as granules. These granules can then be easily melted and molded into new products, closing the loop on the plastic lifecycle and reducing the need for virgin plastic production. This not only helps to conserve natural resources but also minimizes the environmental impact of plastic waste.

The granulation process is an essential step in plastic recycling, and {Company name} understands the importance of delivering top-of-the-line equipment to its customers. Each granulator is precision-engineered to deliver high performance, energy efficiency, and consistent output, ensuring that plastic waste is effectively transformed into valuable raw materials for new production cycles.

One of the key factors that sets {Company name} apart from its competitors is its focus on customization. {Company name} recognizes that different plastic waste materials may require different processing parameters, and as such, offers a range of granulator models to accommodate various plastics, processing capacities, and specific operational requirements. This flexibility allows customers to select the ideal granulation solution for their unique needs, ensuring maximum efficiency and productivity.

In addition to its commitment to product quality, {Company name} is dedicated to providing exceptional customer support and aftersales service. The company's team of experts works closely with clients to understand their recycling challenges and recommend the most suitable granulation solutions. Furthermore, {Company name} offers comprehensive training and technical assistance to ensure that customers can optimize the performance of their granulators and achieve the best possible results.

{Company name} also prioritizes sustainability in its own operations, striving to minimize waste, energy consumption, and environmental impact throughout its manufacturing processes. By embracing eco-friendly practices and technologies, {Company name} sets an example for the industry and demonstrates its dedication to promoting a circular economy for plastics.

As the global demand for recycled plastic continues to grow, {Company name} remains at the forefront of the industry, continuously refining its granulator technology and expanding its product range to meet evolving market needs. With a focus on innovation, reliability, and customer satisfaction, {Company name} is poised to continue making a significant impact in the field of plastic recycling for years to come.

In conclusion, plastic granulators are essential tools for efficient and sustainable plastic recycling, and {Company name} is a trusted leader in providing top-quality granulation solutions to the industry. As the demand for recycled plastic materials continues to rise, {Company name} remains committed to delivering innovative, customized, and eco-friendly granulator technologies that empower businesses to transform plastic waste into valuable resources. With a focus on product excellence and customer support, {Company name} is driving positive change in the recycling landscape and contributing to a greener, more sustainable future.

Company News & Blog

Best Plastic Recycling Pelletizer Machine for Efficient Waste Management

Plastic recycling is a pressing issue in modern society, with more and more companies and individuals realizing the importance of finding sustainable solutions for plastic waste. In line with this growing concern, {Company Name} has taken a significant step towards addressing the problem with the introduction of their state-of-the-art Plastic Recycling Pelletizer Machine.The Plastic Recycling Pelletizer Machine is designed to efficiently process plastic waste and turn it into reusable plastic pellets. This innovative solution not only helps in reducing the amount of plastic going into landfills but also provides a sustainable source of raw material for the manufacturing industry.{Company Name} has a long-standing reputation for producing high-quality industrial machines, and the Plastic Recycling Pelletizer Machine is no exception. It is built with cutting-edge technology and is capable of processing a wide range of plastic materials, including PET, PVC, HDPE, and LDPE, among others. This versatility makes it a valuable asset for businesses in various sectors, including plastic manufacturing, recycling facilities, and waste management companies.One of the key features of the Plastic Recycling Pelletizer Machine is its high efficiency. The machine is equipped with advanced shredding and extrusion units that can handle large volumes of plastic waste with minimal energy consumption. This not only makes the process cost-effective but also reduces the overall carbon footprint of plastic recycling efforts.In addition to its efficiency, the Plastic Recycling Pelletizer Machine is also designed for ease of use and maintenance. It is equipped with a user-friendly interface that allows operators to monitor and control the entire process with ease. Furthermore, the machine is built to withstand the rigors of continuous operation, ensuring maximum uptime and productivity for businesses that rely on it for their plastic recycling needs.{Company Name} is dedicated to providing comprehensive support to its customers, and the introduction of the Plastic Recycling Pelletizer Machine is no exception. The company offers installation and training services to ensure that its customers can integrate the machine seamlessly into their operations. Additionally, their team of experienced technicians is always available to provide ongoing technical support and maintenance services, ensuring that the machine continues to perform at its best.The introduction of the Plastic Recycling Pelletizer Machine is a testament to {Company Name}'s commitment to sustainability and environmental responsibility. By offering a reliable and efficient solution for plastic recycling, the company is playing a crucial role in promoting a circular economy and reducing the environmental impact of plastic waste.The Plastic Recycling Pelletizer Machine is set to make a significant impact in the plastic recycling industry, providing businesses with a viable and sustainable solution for managing plastic waste. With its advanced technology, high efficiency, and comprehensive support services, it is poised to become a game-changer in the fight against plastic pollution.As the demand for sustainable solutions continues to grow, {Company Name} is proud to be at the forefront of driving positive change in the industry. With the Plastic Recycling Pelletizer Machine, the company is setting a new standard for plastic recycling and paving the way for a more sustainable future.

Understanding the Cost of Extruder Machines: What You Need to Know

Cost Of Extruder MachineThe cost of an extruder machine is a crucial consideration for companies in the manufacturing and processing industries. Extruder machines are utilized in various industries for the production of a wide range of products including food items, plastic materials, rubber, and more. The cost of an extruder machine can vary depending on several factors such as size, capacity, features, and brand. One of the leading manufacturers of extruder machines is [Company Name]. With over [X] years of experience in the industry, [Company Name] has a reputation for producing high-quality and innovative extruder machines that cater to the diverse needs of their customers. As a company, [Company Name] is committed to providing their customers with state-of-the-art extruder machines that are not only efficient but also cost-effective.When it comes to the cost of extruder machines, it is important to consider the specific requirements of the manufacturing or processing operations. The cost of an extruder machine can range from a few thousand dollars to several hundred thousand dollars. The size and capacity of the machine play a significant role in determining the cost, with larger and more powerful machines typically being more expensive.In addition to size and capacity, the features and capabilities of the extruder machine can also impact its cost. Extruder machines come with a variety of features such as advanced control systems, multiple extrusion capabilities, automated functions, and more. These features can add to the overall cost of the machine but are often essential for companies looking to optimize their production processes.Furthermore, the brand of the extruder machine can also influence its cost. While there are numerous manufacturers of extruder machines in the market, established and reputable brands like [Company Name] may come with a higher price tag due to their quality, reliability, and after-sales support. However, investing in a well-known brand can also provide companies with the assurance of superior performance and longevity.It is also important to note that the cost of an extruder machine is not limited to its initial purchase price. Companies must consider additional expenses such as installation, training, maintenance, and ongoing operational costs. These factors should be carefully evaluated to ensure that the total cost of ownership of the extruder machine aligns with the company's budget and operational requirements.In conclusion, the cost of an extruder machine can vary based on factors such as size, capacity, features, and brand. As a leading manufacturer in the industry, [Company Name] is dedicated to providing their customers with cost-effective extruder machines that deliver exceptional performance and value. By understanding their specific production needs and carefully evaluating the various cost considerations, companies can make informed decisions when investing in an extruder machine that will contribute to their success and growth in the industry.

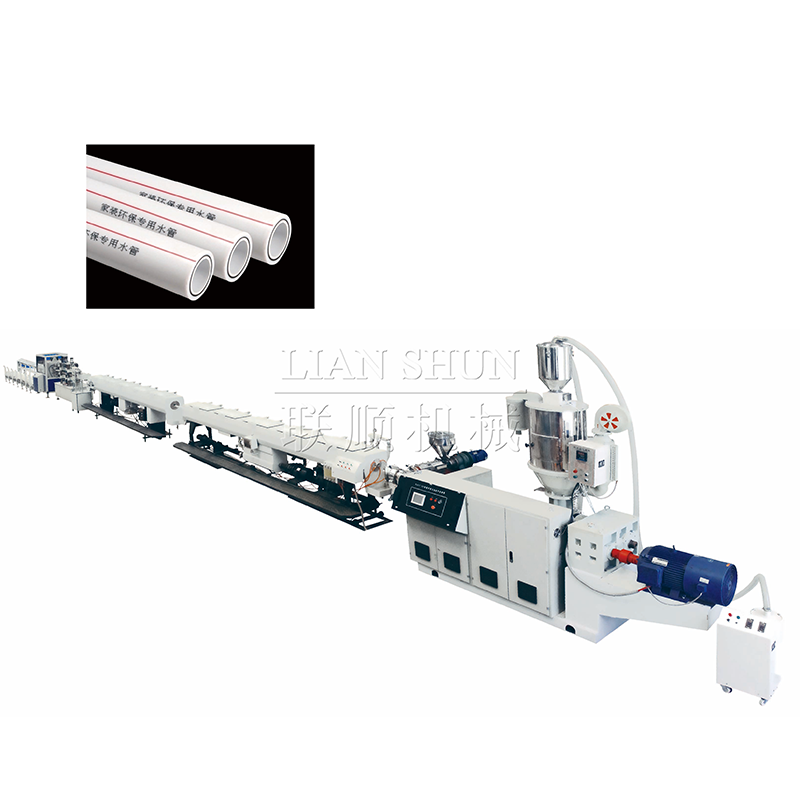

How Plastic Pipe Extruders are Shaping the Manufacturing Industry

Plastic Pipe Extruder Unveils Groundbreaking Innovation in Pipeline TechnologyThe plastic pipe extrusion industry is rapidly evolving, and leading the way in this technological revolution is [Company Name], a global leader in the manufacturing of high-quality plastic pipe products. With a commitment to innovation and sustainability, [Company Name] has recently unveiled their latest groundbreaking innovation in pipeline technology that is set to revolutionize the industry.The newly developed product, which leverages state-of-the-art extrusion technology, promises to deliver unparalleled performance and durability, while also addressing the growing concerns for environmental sustainability. Unlike traditional metal pipes, the plastic pipes produced by [Company Name] are lightweight, corrosion-resistant, and highly cost-effective, making them an ideal solution for a wide range of applications, including water distribution, sewer systems, and industrial piping.[Company Name] has long been recognized for its expertise in plastic pipe extrusion, boasting a rich history of innovation and a proven track record of delivering superior products to a global customer base. With a dedicated team of research and development experts, the company has continually pushed the boundaries of what is possible in the world of plastic pipe manufacturing.In addition to their commitment to technological advancement, [Company Name] also places a strong emphasis on sustainability and environmental responsibility. The newly developed plastic pipes are made from high-quality, recyclable materials, ensuring that the environmental impact of their production and usage is minimized. This aligns with the company's broader mission to promote a more sustainable and eco-friendly approach to pipeline infrastructure.Furthermore, [Company Name] has implemented stringent quality control measures throughout the production process, ensuring that each plastic pipe that rolls off their assembly line meets the highest standards of excellence. This dedication to quality has earned the company a sterling reputation within the industry, with customers around the world trusting [Company Name] to provide reliable and long-lasting pipeline solutions.With the unveiling of their latest innovation, [Company Name] is poised to reinforce its position as an industry leader in plastic pipe extrusion. The new product is expected to set a new benchmark for performance and reliability, offering customers a cutting-edge solution that meets the demands of modern infrastructure projects.Commenting on the launch of the new product, [Company Name]'s CEO expressed his confidence in the capabilities of the innovative plastic pipe extrusion technology, stating, "We are proud to introduce this groundbreaking innovation to the market. Our team has worked tirelessly to develop a product that not only outperforms traditional pipeline materials but also aligns with our commitment to sustainability. We believe that this innovation will have a transformative impact on the industry, and we are excited to see the positive outcomes it will bring to our customers and the environment."As the global demand for high-quality, sustainable pipeline solutions continues to grow, [Company Name] is well-positioned to meet the evolving needs of the market. Their dedication to innovation, quality, and environmental responsibility sets them apart as a leading force in the plastic pipe extrusion industry, and their latest breakthrough is a testament to their ongoing pursuit of excellence.In conclusion, the unveiling of [Company Name]'s groundbreaking innovation in pipeline technology represents a significant milestone in the evolution of the plastic pipe extrusion industry. Through their commitment to innovation, sustainability, and quality, [Company Name] continues to lead the way in providing cutting-edge solutions for infrastructure projects around the world. With their latest product set to redefine the standards for pipeline performance and durability, [Company Name] is undeniably shaping the future of the industry.

High-Quality Corrugated Pipe Machine for Sale - Efficient and Durable

Industrial Machinery Manufacturing Company is proud to announce the launch of their latest innovation, the Corrugated Pipe Machine. This state-of-the-art machine is set to revolutionize the manufacturing process for corrugated pipes, offering advanced technology and high efficiency for our valued customers.The Corrugated Pipe Machine is designed to produce high-quality corrugated pipes with precision and speed. It is equipped with advanced automation and control systems, ensuring consistent and reliable production. This cutting-edge machine can accommodate various materials, including PVC, HDPE, and PP, providing flexibility for different manufacturing requirements.The launch of the Corrugated Pipe Machine is the result of extensive research and development efforts by our team of experienced engineers and technicians. We have utilized our expertise in industrial machinery manufacturing to create a solution that meets the evolving needs of the corrugated pipe industry. The machine is engineered to deliver superior performance while minimizing downtime and maintenance requirements.The Corrugated Pipe Machine is easy to operate, thanks to its user-friendly interface and intuitive controls. It offers a range of customization options, allowing our customers to tailor the production process to their specific requirements. Whether it's adjusting the pipe diameter, wall thickness, or the production speed, this machine offers unparalleled flexibility and versatility.In addition to its impressive performance capabilities, the Corrugated Pipe Machine is also designed with sustainability in mind. It incorporates energy-saving features and efficient production processes, helping our customers reduce their environmental footprint while maintaining cost-effective operations."We are thrilled to introduce the Corrugated Pipe Machine to the market," said the CEO of Industrial Machinery Manufacturing Company. "This cutting-edge innovation is a testament to our commitment to providing our customers with the best-in-class solutions. We are confident that this machine will set new standards in the corrugated pipe manufacturing industry, offering unmatched performance and efficiency."The Corrugated Pipe Machine is available in various configurations to accommodate different production capacities and requirements. Whether our customers are looking to upgrade their existing production line or establish a new manufacturing facility, this machine offers a scalable solution to meet their needs.To complement the launch of the Corrugated Pipe Machine, Industrial Machinery Manufacturing Company is also offering comprehensive after-sales support services. Our team of skilled technicians is dedicated to ensuring seamless installation, training, and technical assistance for our customers, enabling them to maximize the potential of this innovative machine.As a leading industrial machinery manufacturer, Industrial Machinery Manufacturing Company takes pride in delivering cutting-edge solutions that empower our customers to thrive in today's competitive market. The Corrugated Pipe Machine exemplifies our commitment to innovation, quality, and customer satisfaction.In conclusion, the launch of the Corrugated Pipe Machine is a significant milestone for Industrial Machinery Manufacturing Company and the corrugated pipe manufacturing industry as a whole. This advanced machine is set to redefine the production process, offering unmatched performance, efficiency, and flexibility for our valued customers. With its innovative features and sustainable design, the Corrugated Pipe Machine is poised to set new benchmarks in the industry and empower manufacturers to achieve greater success.

Efficient Waste Crusher Machine - Simplifying Waste Management!

Title: Cutting-edge Waste Crusher Machine Revolutionizes Waste ManagementIntroduction:In an effort to tackle the growing global problem of waste management, {Company Name} has unveiled its latest innovation - a cutting-edge Waste Crusher Machine. The machine promises to revolutionize waste disposal by providing efficient and sustainable solutions for both residential and commercial settings. With features like advanced technology, user-friendly design, and environmentally conscious operations, this state-of-the-art machine is set to transform the way we handle waste on a large scale.Setting the Stage for Sustainable Waste Management:In an increasingly consumer-driven world, managing waste has become a significant challenge. Traditional waste management systems are often inadequate, leading to harmful environmental consequences. Recognizing this issue, {Company Name} has developed a comprehensive solution with the Waste Crusher Machine.Key Features and Benefits:The Waste Crusher Machine stands out for several key features that set it apart from conventional waste management systems:1. Advanced Crushing Technology: The machine integrates advanced crushing technology to efficiently reduce waste volume. Its superior capabilities allow for the effective processing of various waste materials, including plastics, glass, paper, and organic waste.2. Robust Design: Built to withstand heavy-duty use, the Waste Crusher Machine is equipped with a sturdy construction that ensures optimal performance and durability. This design feature guarantees long-term operational efficiency, reducing the need for frequent repairs or replacements.3. User-Friendly Interface: With a user-friendly interface, the Waste Crusher Machine can be easily operated by individuals of all skill levels. The intuitive controls make waste disposal a hassle-free process, saving time and effort for users.4. Environmentally Conscious: Committed to sustainability, {Company Name}'s Waste Crusher Machine promotes eco-friendly waste management. By reducing waste volume and enabling efficient recycling, the machine significantly minimizes the environmental impact associated with waste disposal.5. Versatile Applications: The Waste Crusher Machine is designed to cater to a wide range of waste management needs. Whether in residential areas, commercial properties, or industrial facilities, the machine is adaptable to various environments, making it a versatile solution for waste disposal.A Step Towards a Greener Future:With the introduction of the Waste Crusher Machine, {Company Name} aims to spearhead the transition towards a greener and more sustainable waste management approach. By providing an innovative solution that streamlines waste processing and promotes recycling, this machine has the potential to improve the overall efficiency of waste management systems worldwide.Furthermore, the implementation of the Waste Crusher Machine can help reduce the strain on landfills, which are rapidly filling up due to the ever-increasing volume of waste. With its compact design and efficient waste reduction capabilities, this solution paves the way for a more environmentally conscious future.Conclusion:{Company Name}'s Waste Crusher Machine represents a significant step forward in waste management technology. With its advanced features, user-friendly design, and eco-friendly operations, the machine offers a comprehensive solution to the global waste management problem. By promoting efficient waste processing and recycling, this innovation has the potential to transform the way we handle waste on a large scale, paving the way towards a greener and more sustainable future.

New Co Extruder Technology Revolutionizes Plastic Production

The Co Extruder market is expected to witness significant growth in the coming years, according to a new research report. The report highlights the key factors driving the market and provides a detailed analysis of the current and future trends.The Co Extruder is a versatile and efficient machine that is used for the extrusion of various materials. It is commonly used in the plastic and food industries for the production of a wide range of products. The machine features a twin screw design that allows for the simultaneous extrusion of multiple materials, resulting in a more efficient and cost-effective process.One of the key players in the Co Extruder market is a leading manufacturer and supplier of plastic processing machinery. The company has a diverse product portfolio that includes extruders, blow molding machines, and other related equipment. With a strong focus on innovation and quality, the company has established itself as a trusted partner for customers around the world.The Co Extruder offered by the company is known for its high performance and reliability. It is designed to provide precise control over the extrusion process, resulting in consistent and high-quality output. The machine is also equipped with advanced features that enhance productivity and reduce downtime, making it an ideal choice for manufacturers looking to improve their production efficiency.In addition to its advanced technology, the company also offers comprehensive customer support services. From installation and training to maintenance and technical assistance, the company is committed to ensuring that its customers get the most out of their Co Extruder. With a global network of service centers and distributors, the company is able to provide timely and efficient support to customers in any location.The Co Extruder market is driven by several factors, including the growing demand for sustainable and cost-effective production solutions. With the increasing focus on environmental sustainability, manufacturers are looking for new ways to reduce waste and improve efficiency. The Co Extruder offers a number of benefits in this regard, including the ability to process a wide range of materials and the potential for energy savings.Furthermore, the Co Extruder market is also being propelled by the increasing adoption of advanced technologies in the manufacturing industry. As companies seek to stay ahead of the competition, they are investing in cutting-edge equipment that can help them improve their production processes. The Co Extruder is well-suited to meet this demand, with its advanced features and capabilities that can help manufacturers stay competitive in today's dynamic market.Looking ahead, the Co Extruder market is expected to continue its growth trajectory as manufacturers across various industries recognize the benefits of this technology. With its versatility, efficiency, and advanced features, the Co Extruder is poised to become an essential tool for manufacturers seeking to enhance their production capabilities.In conclusion, the Co Extruder market is on a strong growth trajectory, driven by the demand for sustainable and efficient production solutions. As one of the key players in this market, the company is well-positioned to capitalize on this trend with its innovative and high-quality Co Extruder. With a strong focus on technology and customer support, the company is poised to meet the evolving needs of manufacturers around the world.

The Ultimate Guide to Pelletizing Machines: Everything You Need to Know

PP Pelletizing Machine Revolutionizes Plastic RecyclingThe plastic industry has experienced a significant revolution as the demand for more sustainable and environmentally friendly practices has increased in recent years. As a response to this growing need, {Company Name} has introduced the latest innovation in plastic recycling - the PP Pelletizing Machine. This cutting-edge technology promises to revolutionize the plastic recycling process, making it more efficient and environmentally friendly than ever before.{Company Name} has been a leading force in the plastic recycling industry for over a decade, constantly striving to develop innovative solutions to address the environmental challenges posed by plastic waste. The company’s commitment to sustainability and innovation has led to the development of the PP Pelletizing Machine, which is set to change the way plastic recycling is done.The PP Pelletizing Machine is designed to process polypropylene (PP) plastic waste into high-quality pellets that can be used to manufacture new plastic products. By converting PP waste into pellets, the machine enables the plastic to be reused in a closed-loop system, reducing the need for virgin plastic production and minimizing environmental impact.One of the key features of the PP Pelletizing Machine is its advanced technology, which allows for efficient and precise processing of PP plastic waste. The machine is equipped with state-of-the-art equipment that ensures the quality and consistency of the pellets produced, making them suitable for a wide range of plastic manufacturing applications.Furthermore, the PP Pelletizing Machine is highly versatile, capable of processing different types of PP plastic waste, including films, fibers, and injection-molded parts. This flexibility makes it an ideal solution for businesses and industries looking to recycle their PP waste in an environmentally responsible manner.In addition to its technical capabilities, the PP Pelletizing Machine is also designed with user convenience in mind. Its user-friendly interface and automated processes make it easy to operate, requiring minimal training for operators. This allows businesses to integrate the machine into their existing recycling processes with ease, maximizing their recycling efficiency and output.The introduction of the PP Pelletizing Machine signifies a major milestone for {Company Name} and the plastic recycling industry as a whole. With this innovative technology, the company is paving the way for a more sustainable and circular approach to plastic recycling, contributing to the global effort to reduce plastic waste and promote a more sustainable future.The PP Pelletizing Machine is already showing promising results in various industrial applications, with businesses around the world expressing interest in adopting this groundbreaking technology. By investing in the PP Pelletizing Machine, companies can not only enhance their sustainability credentials but also contribute to the global effort to reduce plastic pollution and conserve natural resources.As the demand for sustainable plastic recycling solutions continues to grow, {Company Name} remains committed to driving innovation and setting new standards in the industry. The PP Pelletizing Machine is a testament to the company’s dedication to sustainability and its ability to deliver cutting-edge solutions that address the environmental challenges of our time.In conclusion, the introduction of the PP Pelletizing Machine by {Company Name} marks a significant leap forward in the plastic recycling industry. With its advanced technology, versatility, and user-friendly design, this innovative machine is set to revolutionize the way PP plastic waste is recycled, offering a more efficient and sustainable solution for businesses worldwide. As {Company Name} continues to lead the way in plastic recycling innovation, the PP Pelletizing Machine is poised to make a lasting impact on the industry, driving positive change for the environment and future generations.

Powerful Pipe Cutting Machines for Efficient Operations

Pipe Cutting Machines is a leading company that specializes in the manufacturing and distribution of high-quality pipe cutting and beveling machines. With years of experience in the industry, the company has established itself as a trusted provider of innovative solutions for pipe cutting needs. Their cutting-edge technology and commitment to excellence have made them a go-to source for businesses looking to streamline their operations and improve efficiency.The company's line of pipe cutting machines is designed to meet the diverse needs of various industries, including oil and gas, construction, and manufacturing. Their machines are capable of cutting and beveling pipes of various materials, sizes, and thicknesses, making them an ideal choice for a wide range of applications. Whether it's a small-scale project or a large industrial operation, Pipe Cutting Machines has the right equipment to get the job done efficiently and accurately.One of the key advantages of Pipe Cutting Machines is their commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. This dedication to innovation has allowed them to develop state-of-the-art pipe cutting machines that are not only highly precise but also incredibly user-friendly.In addition to their cutting-edge technology, Pipe Cutting Machines is known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and provide tailored solutions that meet and exceed their expectations. Whether it's customizing a machine to fit a unique application or providing technical assistance, Pipe Cutting Machines is dedicated to ensuring the success of its customers.Recently, Pipe Cutting Machines introduced a new line of pipe cutting machines that have been garnering attention in the industry. These cutting machines incorporate the latest advancements in technology to deliver unmatched performance and efficiency. With features such as automatic feed control, precision cutting, and remote operation capabilities, these machines are revolutionizing the way pipe cutting is done.One of the key highlights of the new line of pipe cutting machines is their versatility. They are designed to handle a wide range of pipe materials, including steel, stainless steel, aluminum, and more. This flexibility makes them an ideal choice for businesses that work with different types of materials and need a reliable and efficient cutting solution.The new line of pipe cutting machines also comes with advanced safety features to ensure the well-being of operators and workers. With built-in safety guards, emergency stop buttons, and automatic shut-off mechanisms, these machines prioritize the safety of everyone involved in the cutting process.Furthermore, Pipe Cutting Machines has also incorporated smart technology into their new line of machines. These machines are equipped with advanced software and connectivity features that allow for remote monitoring and control. This means that operators can easily monitor the cutting process and make adjustments as needed from a distance, improving overall efficiency and productivity.The introduction of this new line of pipe cutting machines is a testament to Pipe Cutting Machines' ongoing commitment to innovation and excellence in the industry. By continuously pushing the boundaries of what is possible in pipe cutting technology, the company is helping businesses around the world improve their operations and achieve outstanding results.In conclusion, Pipe Cutting Machines has proven itself to be a leader in the industry, offering cutting-edge solutions that meet the evolving needs of businesses. With a dedication to innovation, exceptional customer service, and a new line of advanced pipe cutting machines, the company is well-positioned to continue making a significant impact in the industry for years to come.

Advanced Planetary Cutting Machine for Precision Fabrication

The Planetary Cutting Machine is revolutionizing the field of industrial cutting and shaping, offering unparalleled efficiency, precision, and versatility. This cutting-edge technology is being hailed as a game-changer for manufacturers across a wide range of industries, from automotive and aerospace to construction and renewable energy.The Planetary Cutting Machine is capable of cutting and shaping various materials, including metals, plastics, ceramics, and composites, with exceptional speed and accuracy. The machine's unique planetary motion system allows for simultaneous cutting and shaping in multiple directions, ensuring superior precision and consistency in the final product.One of the key features of the Planetary Cutting Machine is its modular design, which allows for easy customization and integration into existing manufacturing processes. This flexibility makes it an ideal solution for companies looking to upgrade their production capabilities without having to overhaul their entire operations.In addition to its cutting and shaping capabilities, the Planetary Cutting Machine also offers advanced automation and control features, allowing for seamless integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This not only streamlines the production process but also minimizes the risk of human error, resulting in higher-quality finished products.The company behind the Planetary Cutting Machine, [Company Name], is a leading provider of cutting-edge manufacturing solutions. With a rich history of innovation and a commitment to excellence, the company has established itself as a trusted partner for businesses seeking to optimize their production processes and stay ahead of the competition.[Company Name] prides itself on its dedication to research and development, constantly pushing the boundaries of what is possible in the field of industrial cutting and shaping. The Planetary Cutting Machine is the latest in a long line of breakthrough technologies from the company, showcasing its ability to anticipate industry needs and deliver cutting-edge solutions.The company's commitment to customer satisfaction is another key aspect of its success. By working closely with clients to understand their specific needs and challenges, [Company Name] is able to develop tailored solutions that address their unique requirements and deliver tangible results. This customer-centric approach has earned the company a reputation for reliability and innovation in the industry.Looking ahead, [Company Name] is poised to continue its legacy of innovation and excellence, with plans to further expand the capabilities of the Planetary Cutting Machine and explore new applications for this groundbreaking technology. By staying at the forefront of technological advancements and remaining deeply attuned to the needs of its customers, the company is well-positioned to continue shaping the future of industrial manufacturing.In conclusion, the Planetary Cutting Machine represents a significant leap forward in the field of industrial cutting and shaping. Its cutting-edge capabilities, coupled with the expertise and commitment of [Company Name], make it a formidable tool for businesses seeking to elevate their production processes and achieve superior results. As the industry continues to evolve, the Planetary Cutting Machine and its innovative creators are poised to remain at the forefront of this exciting transformation.

High Performance PVC Crushing Machine for Efficient Recycling

Pvc Crushing Machine: The Latest Innovation in Recycling TechnologyIn today's world, the issue of plastic pollution has become a growing concern for environmentalists and policymakers. With the increasing use of plastic materials in various industries, the need for effective recycling solutions has never been more critical. Recognizing the importance of sustainable and eco-friendly practices, {Company Name} has recently introduced a cutting-edge Pvc Crushing Machine that is set to revolutionize the plastic recycling process.{Company Name} is a leading manufacturer and supplier of recycling equipment, with a strong commitment to environmental sustainability. With years of experience in the industry, {Company Name} has earned a reputation for delivering high-quality and innovative solutions that meet the evolving needs of the market.The newly launched Pvc Crushing Machine is a state-of-the-art equipment designed to efficiently process and recycle PVC materials. It is equipped with advanced technology and features a robust construction that ensures durability and reliability. The machine is capable of effectively crushing and granulating PVC waste, turning it into reusable raw materials that can be used in the manufacturing of new products.One of the key highlights of the Pvc Crushing Machine is its high processing capacity, which allows for a significant volume of PVC waste to be processed in a short period. This not only improves the efficiency of the recycling process but also contributes to reducing the environmental impact of plastic pollution. In addition, the machine is designed with user-friendly controls and safety features, making it easy to operate and maintain.{Company Name} has also emphasized the importance of incorporating sustainable practices into its manufacturing processes. The Pvc Crushing Machine is designed to minimize energy consumption and waste generation, further demonstrating {Company Name}'s commitment to environmental responsibility.The introduction of the Pvc Crushing Machine aligns with {Company Name}'s mission to support a circular economy and promote the sustainable use of resources. By providing innovative recycling solutions, {Company Name} aims to encourage businesses and industries to adopt more environmentally friendly practices and reduce their reliance on virgin plastics.In response to the growing demand for sustainable solutions, {Company Name} has already received positive feedback from clients who have integrated the Pvc Crushing Machine into their recycling operations. Many have praised the machine for its efficiency, reliability, and cost-effectiveness, highlighting its potential to make a significant impact on the plastic recycling industry.As the global focus on sustainability continues to grow, {Company Name} remains committed to driving positive change through its innovative products and services. The Pvc Crushing Machine stands as a testament to {Company Name}'s dedication to delivering sustainable and eco-friendly solutions that benefit both businesses and the environment.With the introduction of the Pvc Crushing Machine, {Company Name} is poised to play a pivotal role in advancing the plastic recycling industry and encouraging a more responsible approach to plastic waste management. As the demand for sustainable solutions continues to rise, {Company Name} remains at the forefront of driving innovation and promoting environmental stewardship in the recycling industry.